Rotor for rotary electric machine

A technology for rotating electrical machines and rotors, applied in electrical components, electromechanical devices, electrical components, etc., can solve the problems of reducing the forming dimensional accuracy and increasing the size of the pressing machine, increasing the manufacturing cost, and increasing the pressing load of the manufacturing end plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

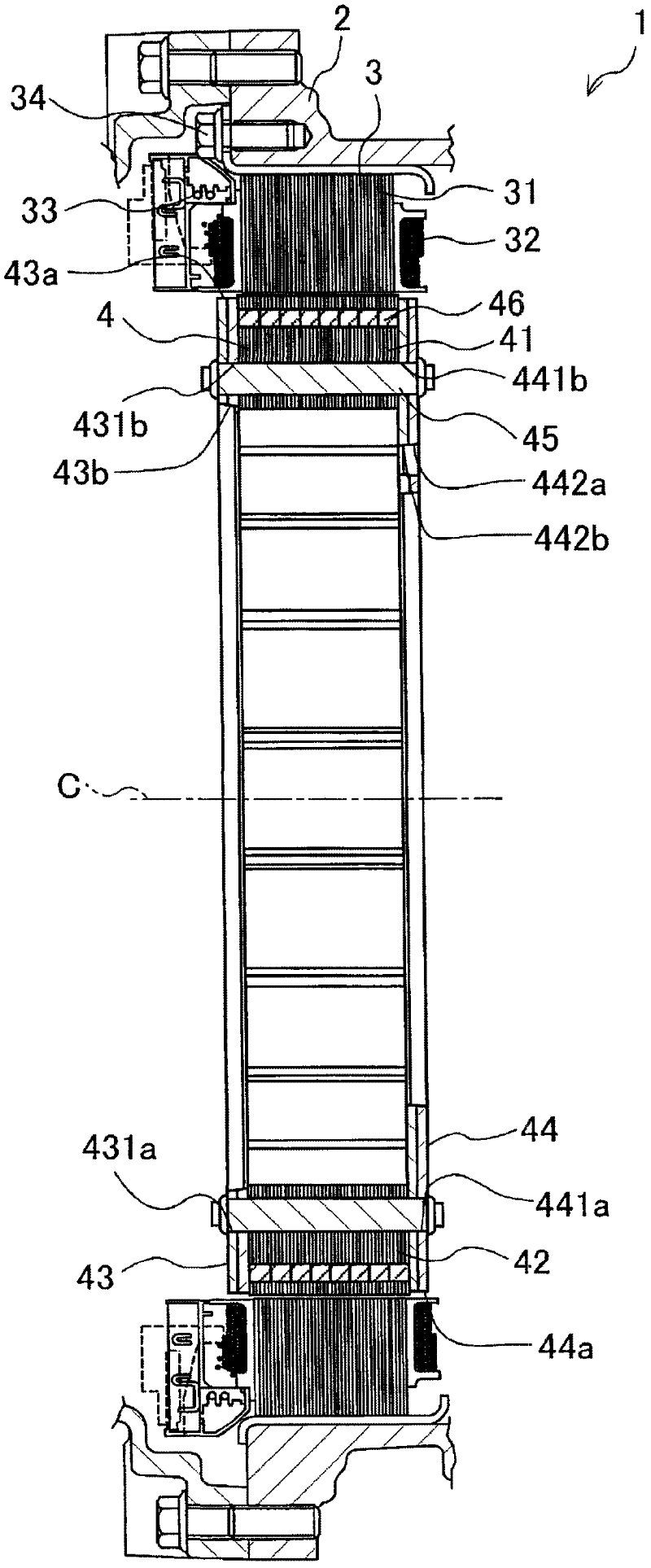

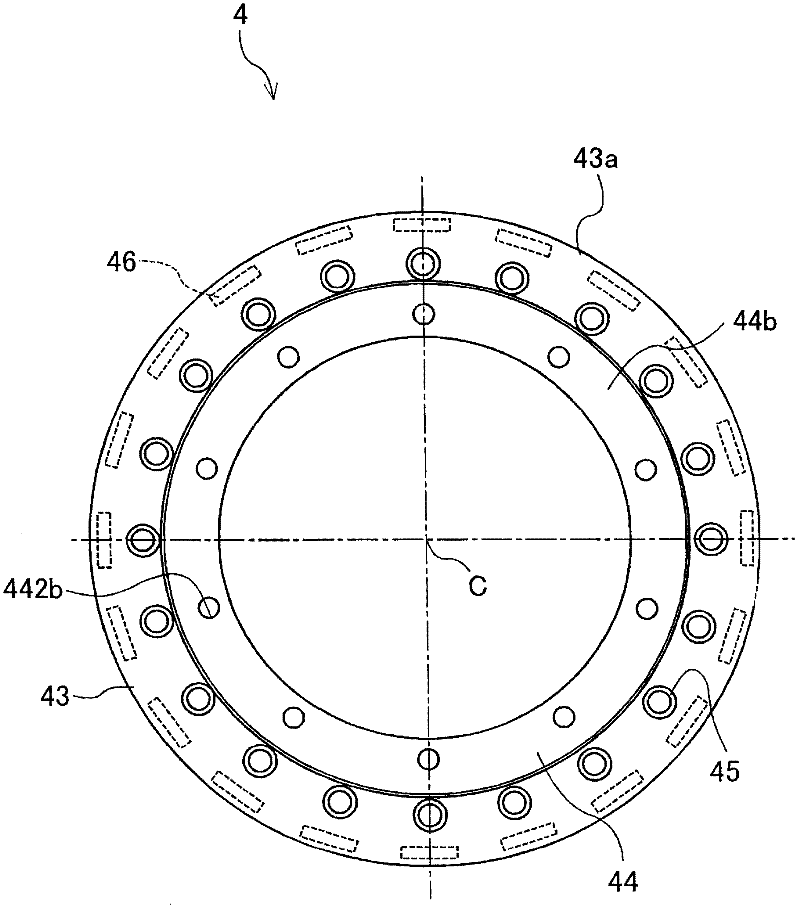

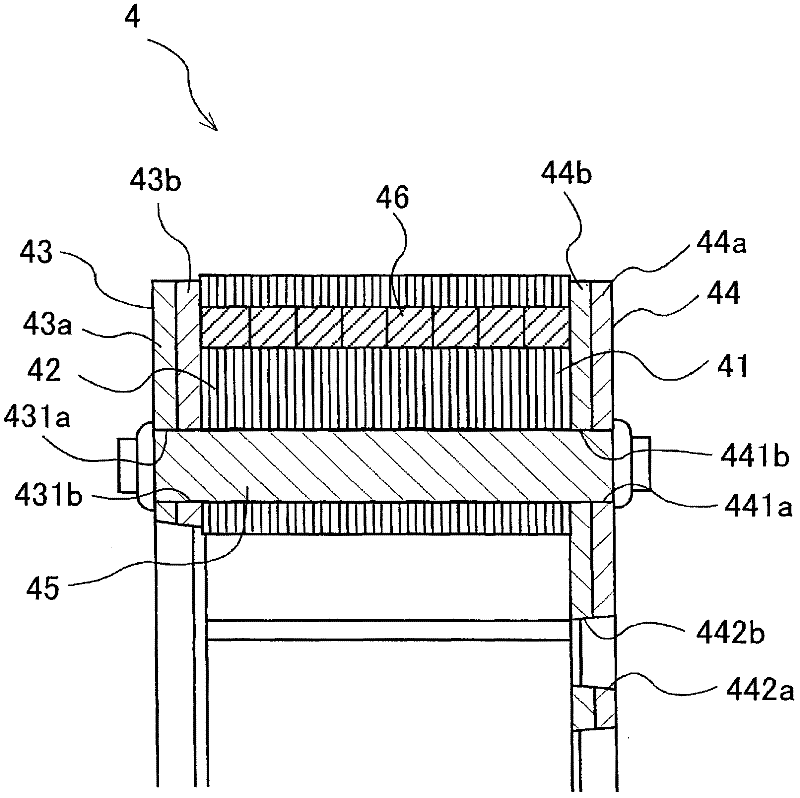

[0028] Below, refer to Figure 1 to Figure 5 , illustrates the rotor 4 of the motor 1 according to the first embodiment.

[0029] The electric motor 1 as the rotating electric machine according to the first embodiment is a synchronous electric motor for driving wheels of a hybrid vehicle. The electric motor 1 is arranged between a clutch device connected to the engine and a transmission. However, the motor 1 of the present embodiment can be applied to any type of motors, such as motors provided in home appliances, and motors driving industrial machines.

[0030] In the following description, unless otherwise specified, the direction of the rotation axis or the axial direction corresponds to the direction along the rotation axis C of the motor 1 (rotor 4), that is, figure 1 Middle left direction. in addition, figure 1 The left side in corresponds to the front side of the vehicle, while figure 1 The right side in corresponds to the rear side of the vehicle.

[0031] Such a...

no. 2 example

[0056] Below, refer to Figure 6 , illustrating the third end plate 47 as the second end plate according to the second embodiment. In the second embodiment, the same constituent elements or parts as those of the first embodiment are given the same reference numerals as those of the first embodiment, and descriptions thereof are omitted. refer to Figure 6 The third end plate 47 according to the second embodiment is explained. Such as Figure 6 As shown, the third end plate 47 of the rotor 4A includes a fifth constituent plate 47a as a third constituent member, and a sixth constituent plate 47b as a fourth constituent member. The fifth constituent plate 47a formed substantially in a ring shape includes twenty fifth holes 471a each being a through hole, and the fastening pins 45 are respectively inserted into the fifth holes 471a. In the same manner as the third constituent plate 44a of the first embodiment, fifth holes 471a are arranged at equal intervals in the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com