Weather-resistant PE gas pipe

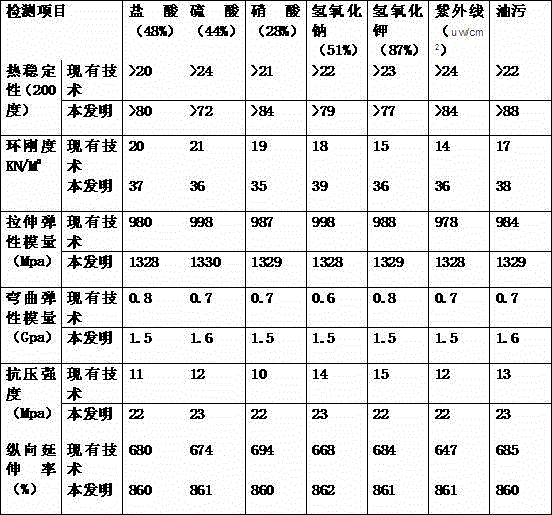

A gas pipe and weather resistance technology, applied in the field of pipes, can solve the problem that the weather resistance cannot achieve satisfactory results, and achieve the effect of increasing the scope of use, good weather resistance, and improving weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A PE gas pipe with good weather resistance, made of the following raw materials in weight percentage: polyethylene (HDPE) 95%, light stabilizer 0.6%, carbon black 0.7%, TNPP 0.7%, isooctyl thioglycolate 0.7%, Di-n-octyltin maleate 0.8%, Zinc oxide 0.4%, Titanium oxide 0.5%, Clay 0.6%.

[0019] The above-mentioned PE gas pipe with good weather resistance, its preparation method comprises the following steps:

[0020] 1) Put polyethylene (HDPE), light stabilizer, carbon black, TNPP, isooctyl thioglycolate, and di-n-octyltin maleate into the plasticizing equipment according to the above weight percentage, heat to 120 degrees, and melt into a melt, spare;

[0021] 2) Put zinc oxide, titanium oxide, and clay into the crushing equipment according to the above weight percentage, crush them into 300 meshes, then put them into the mixing equipment, stir at a speed of 3500r / min for 30min, and mix evenly to make mixed powder A. spare;

[0022] 3) Put the melt produced in step...

Embodiment 2

[0027] A PE gas pipe with good weather resistance, made of the following raw materials in weight percentage: polyethylene (HDPE) 97%, light stabilizer 0.3%, carbon black 0.4%, TNPP 0.3%, thioglycolic acid isooctyl Ester 0.5%, Di-n-octyltin maleate 0.6%, Zinc oxide 0.2%, Titanium oxide 0.3%, Clay 0.4%.

[0028] The above-mentioned PE gas pipe with good weather resistance, its preparation method comprises the following steps:

[0029] 1) Put polyethylene (HDPE), light stabilizer, carbon black, TNPP, isooctyl thioglycolate, and di-n-octyltin maleate into the plasticizing equipment according to the above weight percentage, heat to 150 degrees, and melt into a melt, spare;

[0030] 2) Put zinc oxide, titanium oxide, and clay into the crushing equipment according to the above weight percentage, crush them into 400 meshes, then put them into the mixing equipment, stir at a speed of 3000r / min for 60min, and mix evenly to make mixed powder A. spare;

[0031] 3) Put the melt produc...

Embodiment 3

[0036] A PE gas pipe with good weather resistance, made of the following raw materials in weight percentage: polyethylene (HDPE) 96.1%, light stabilizer 0.5%, carbon black 0.5%, TNPP 0.4%, isooctyl thioglycolate 0.6%, Di-n-octyltin maleate 0.7%, Zinc oxide 0.3%, Titanium oxide 0.4%, Clay 0.5%.

[0037] The above-mentioned PE gas pipe with good weather resistance, its preparation method comprises the following steps:

[0038] 1) Put polyethylene (HDPE), light stabilizer, carbon black, TNPP, isooctyl thioglycolate, and di-n-octyltin maleate into the plasticizing equipment according to the above weight percentage, heat to 130 degrees, and melt into a melt, spare;

[0039] 2) Put zinc oxide, titanium oxide, and clay into the crushing equipment according to the above weight percentage, crush them into 350 meshes, then put them into the mixing equipment, stir at a speed of 3300r / min for 50min, and mix evenly to make mixed powder A. spare;

[0040] 3) Put the melt produced in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com