Method for modifying cigarette style by utilizing waste tobacco shreds

A technology for cigarettes and cut tobacco, which is applied in the field of enhancing the style characteristics of cigarettes and endogenous flavors, can solve the problems of rare comprehensive utilization efficiency of high-quality tobacco leaf raw material resources, and achieve the effects of improving the utilization rate and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] During the processing of Yunyan (A) (a type of cigarette), 30 kg of waste shredded tobacco was collected. First, put 30kg in a 200L extractor, then add 60kg of 95% ethanol at a mass ratio of 1:2, extract for 3 hours, filter with gauze to obtain the extract, and then place the extract in a 100L concentrated The model is concentrated, and the sample is measured until the refractive index n of the sample is D 20 When the value reaches 1.31, about 40kg of its concentrate is obtained. Then 40kg of concentrated liquid is separated by molecular distillation equipment, and the obtained sample is concentrated by a concentrator until its refractive index n D 20 A value of 1.10 yields an endogenous flavor.

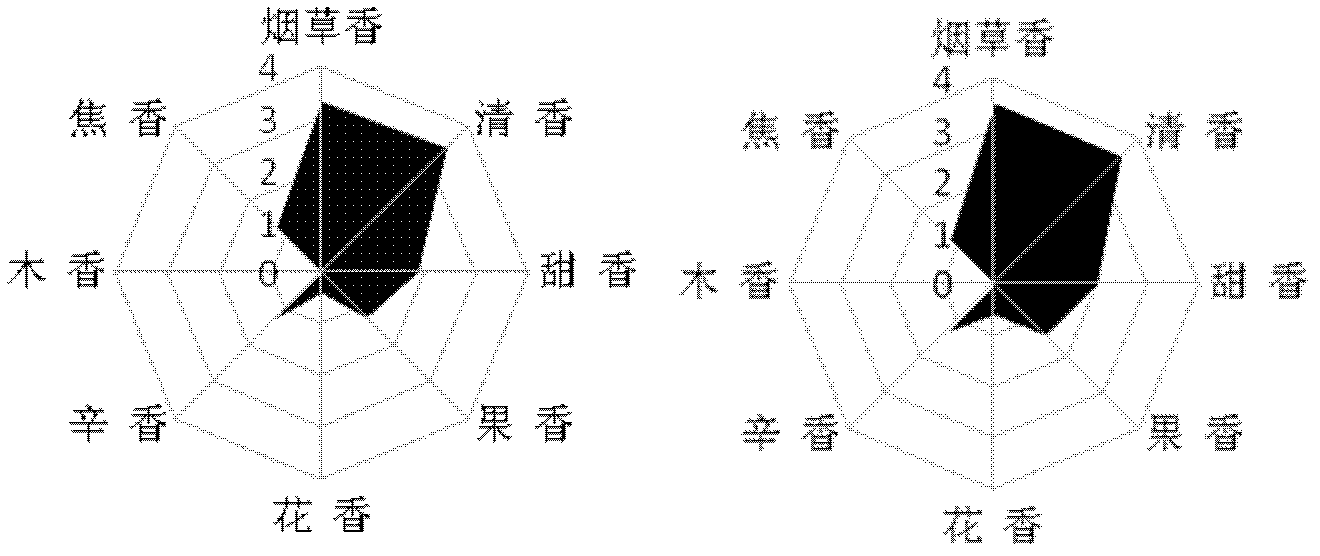

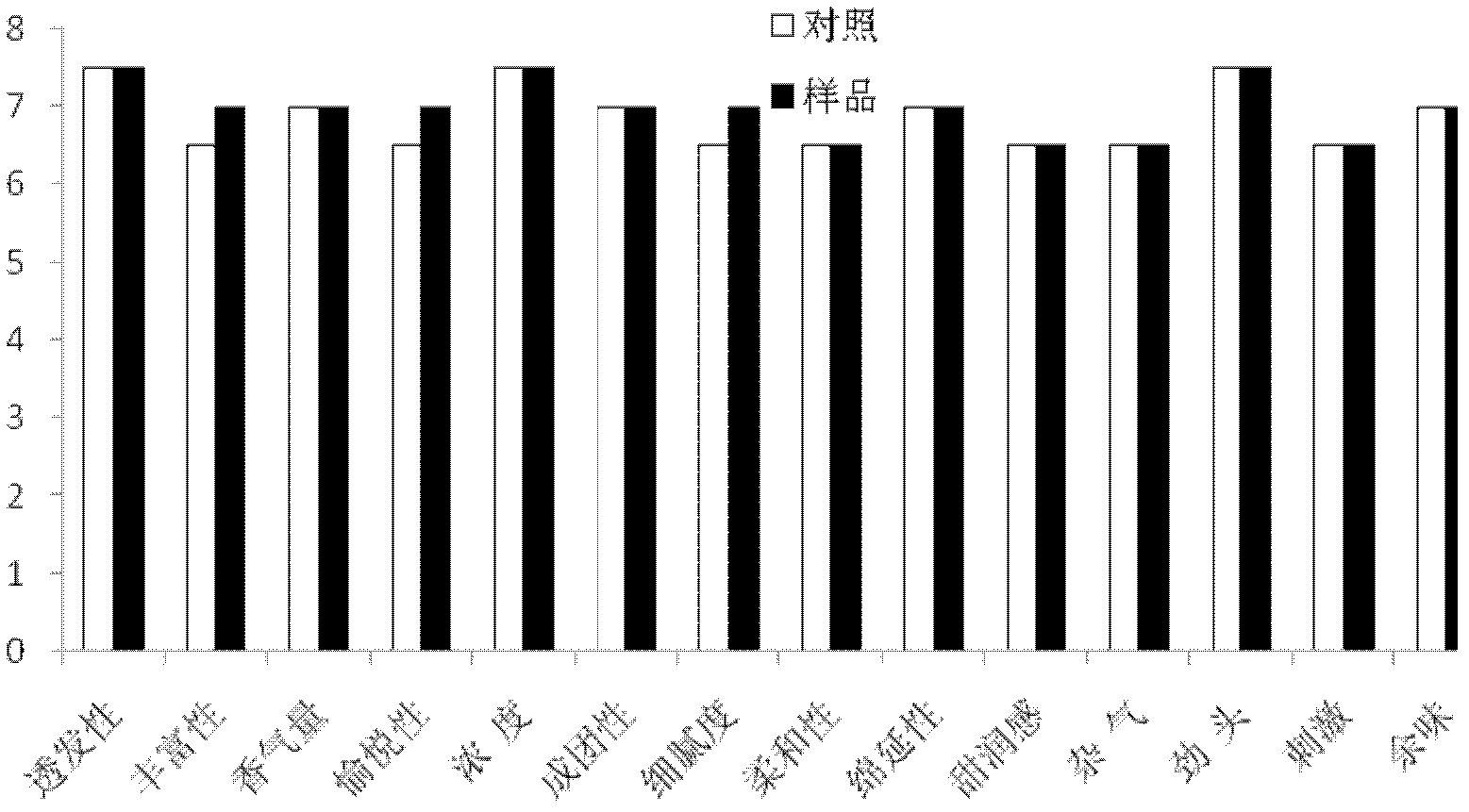

[0023] The obtained endogenous spices were taken, and added in a proportion of 0.3% in the Yunyan (B) (three types of cigarettes) feeding process. After the production was carried out according to the conventional process, the samples were obtained for the determination of...

Embodiment 2

[0027] During the processing of Yunyan (A) (a type of cigarette), 30 kg of waste shredded tobacco was collected. First, put 30kg in a 200L extractor, then add 60kg of 95% ethanol at a mass ratio of 1:2, extract for 3 hours, filter with gauze to obtain the extract, and then place the extract in a 100L concentrated The model is concentrated, and the sample is measured until the refractive index n of the sample is D 20 When the value reaches 1.32, about 40kg of its concentrate is obtained. Then 40kg of concentrated liquid is separated by molecular distillation equipment, and the obtained sample is concentrated by a concentrator until its refractive index n D 20 A value of 1.15 yields an endogenous flavor.

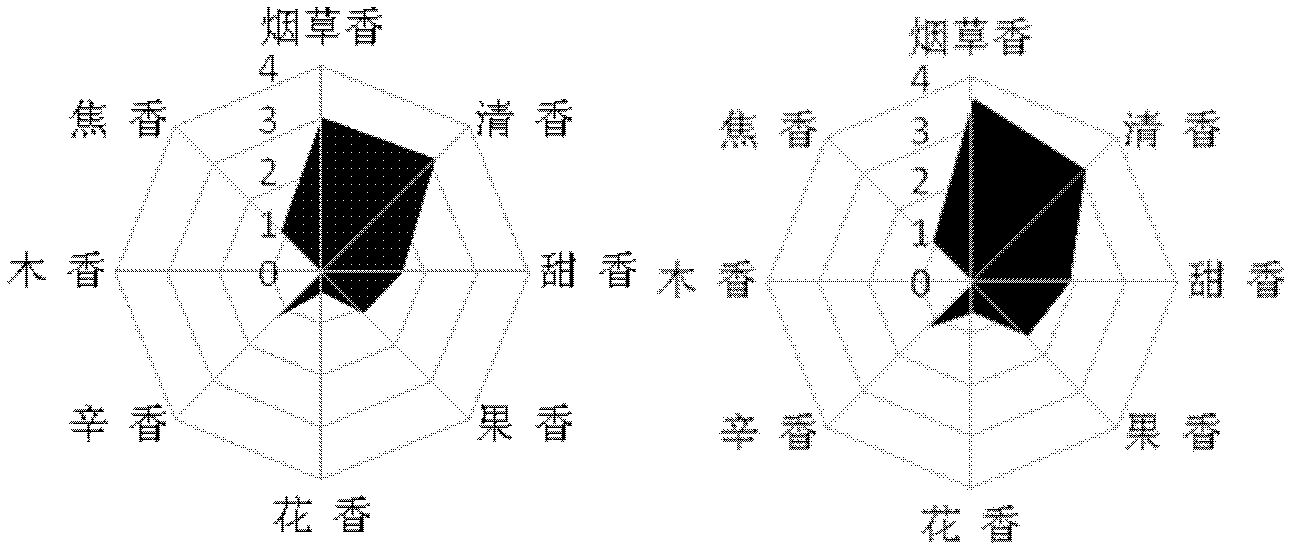

[0028] The obtained endogenous spices were taken, and added in the proportion of 0.5% in the Yunyan (C) (four types of cigarettes) feeding process. After the production was carried out according to the conventional process, the samples were obtained for the determination o...

Embodiment 3

[0032] During the processing of Yunyan (A) (a type of cigarette), 30 kg of waste shredded tobacco was collected. First, put 30kg in a 200L extractor, then add 60kg of 95% ethanol at a mass ratio of 1:2, extract for 3 hours, filter with gauze to obtain the extract, and then place the extract in a 100L concentrated The model is concentrated, and the sample is measured until the refractive index n of the sample is D 20 When the value reaches 1.34, about 40kg of its concentrate is obtained. Then 40kg of concentrated liquid is separated by molecular distillation equipment, and the obtained sample is concentrated by a concentrator until its refractive index n D 20 A value of 1.20 yields an endogenous flavor.

[0033] The obtained endogenous spices were taken and added in a proportion of 0.6% in the Yunyan (D) (category five cigarettes) feeding process. After the production was carried out according to the conventional process, the samples were obtained for the determination of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com