High-efficiency dust collection cyclone separator group

A cyclone separator, a high-efficiency technology, is applied in cyclone devices, devices whose axial directions of the cyclone can be reversed, etc., which can solve the problems of troublesome maintenance, high use cost, complicated structures of electrostatic precipitators and bag filters, etc. Achieve the effect of meeting the requirements of safe operation and reducing the powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

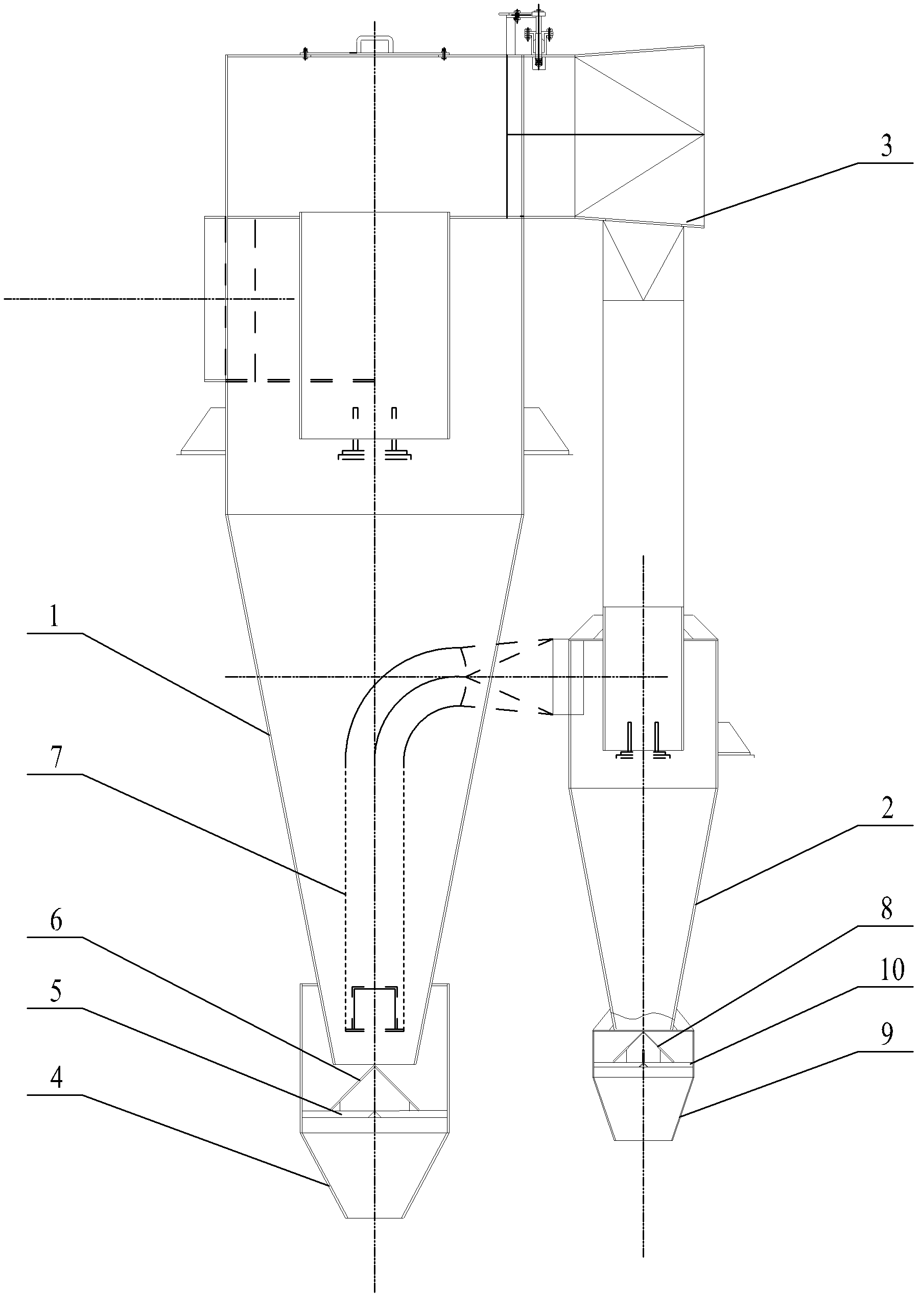

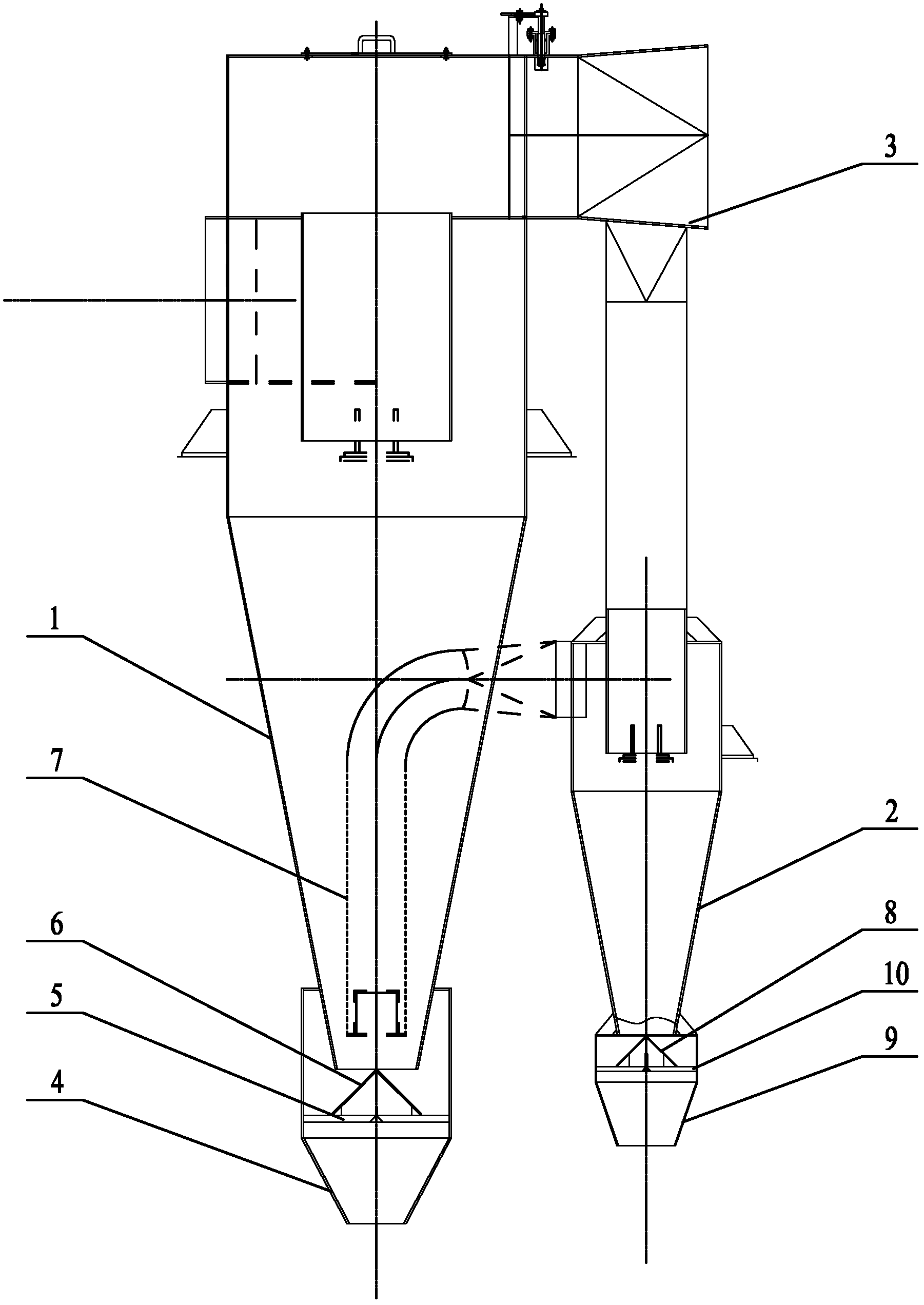

[0009] As shown in the figure: the high-efficiency dust collection cyclone separator group includes a front-stage cyclone separator 1 and a rear-stage cyclone separator 2. Several front-stage cyclone separators 1 are connected in parallel, and the exhaust of the front-stage cyclone separator 1 The pipe is connected in parallel with the exhaust pipe of the back-stage cyclone separator 2 into the exhaust pipe 3, and the ash outlet of each front-stage cyclone separator 1 is connected with the front-stage ash collecting hopper 4, and the outlet of the back-stage cyclone separator 2 The ash outlet is connected with a back-stage ash-collecting bucket 9, and a front-stage installation frame 5 is fixed in the front-stage ash collection bucket 4, and a front-stage conical hood 6 is fixedly installed on the front-stage installation frame 5, and the front-stage conical hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com