Automatic wire feed straightening shaft of steel wire straightening cutting machine

A cutting machine and automatic threading technology, which is applied in the field of automatic threading and straightening shafts of steel wire straightening and cutting machines, can solve the problems of scratches, trouble, low work efficiency, etc., and achieve the effect of good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

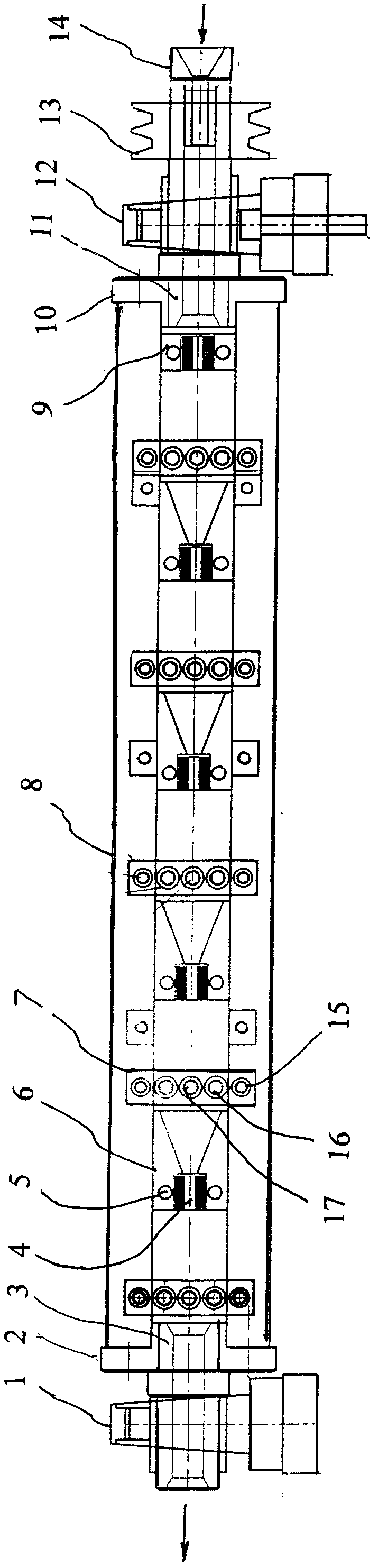

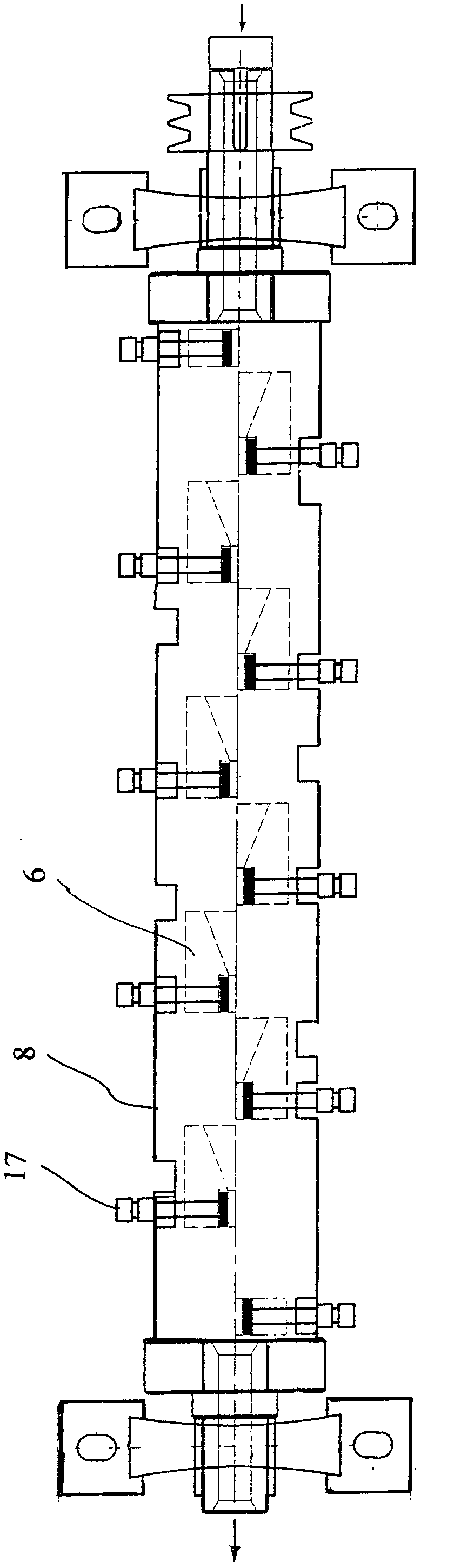

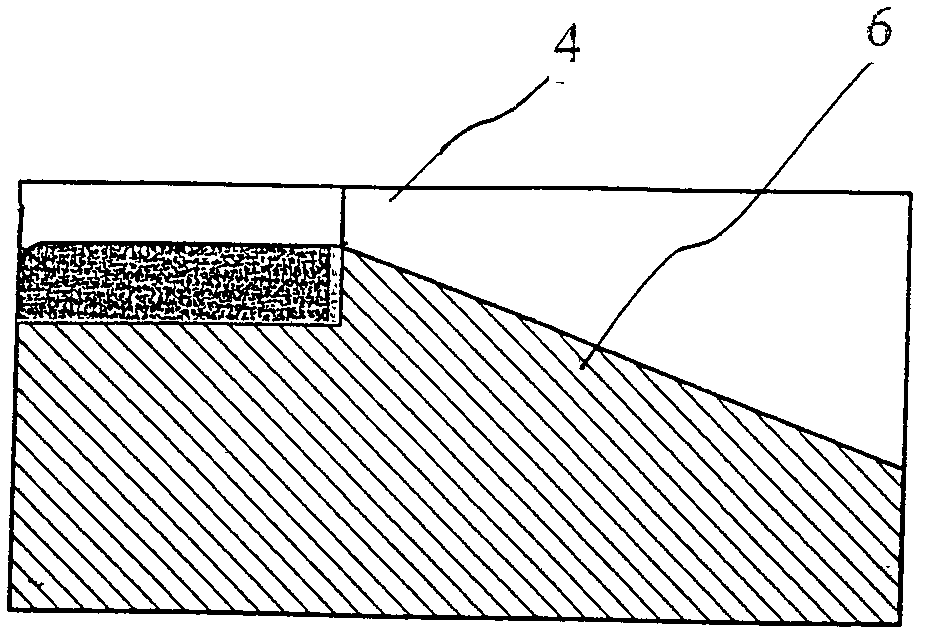

[0017] Such as Figure 1 to Figure 5 As shown, the present embodiment is an automatic wire threading straightening shaft of a steel wire straightening and cutting machine with a ten-level straightening die. The main body 8 is a hollow cylinder welded by two tile-shaped long strip plates with a half-moon shape. The main body 8 is axially provided with long grooves, and both ends are provided with hollow front and rear short shafts 11 / 3, which are mounted on the front and rear bearing blocks 12 / 1 of the fuselage. The front short shaft 11 of the feeding end of the straightening shaft is provided with a guide wire sleeve 14 in front of it, and several straightening modules 6 are arranged in the main body 8, and an adjusting plate 7 is arranged on the outer wall of the main body 8 corresponding to the straightening module 6, and each of the The straightening modules 6 are wedge-shaped and arranged at intervals on opposite sides of the inner wall of the straightening shaft. The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com