Vibration friction welder

A vibration friction and welding machine technology, which is applied in the field of welding equipment, can solve the problems of troublesome repair and maintenance, inability to weld, high production cost, etc., and achieve the effect of good sealing effect, less component parts and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described below in conjunction with accompanying drawing.

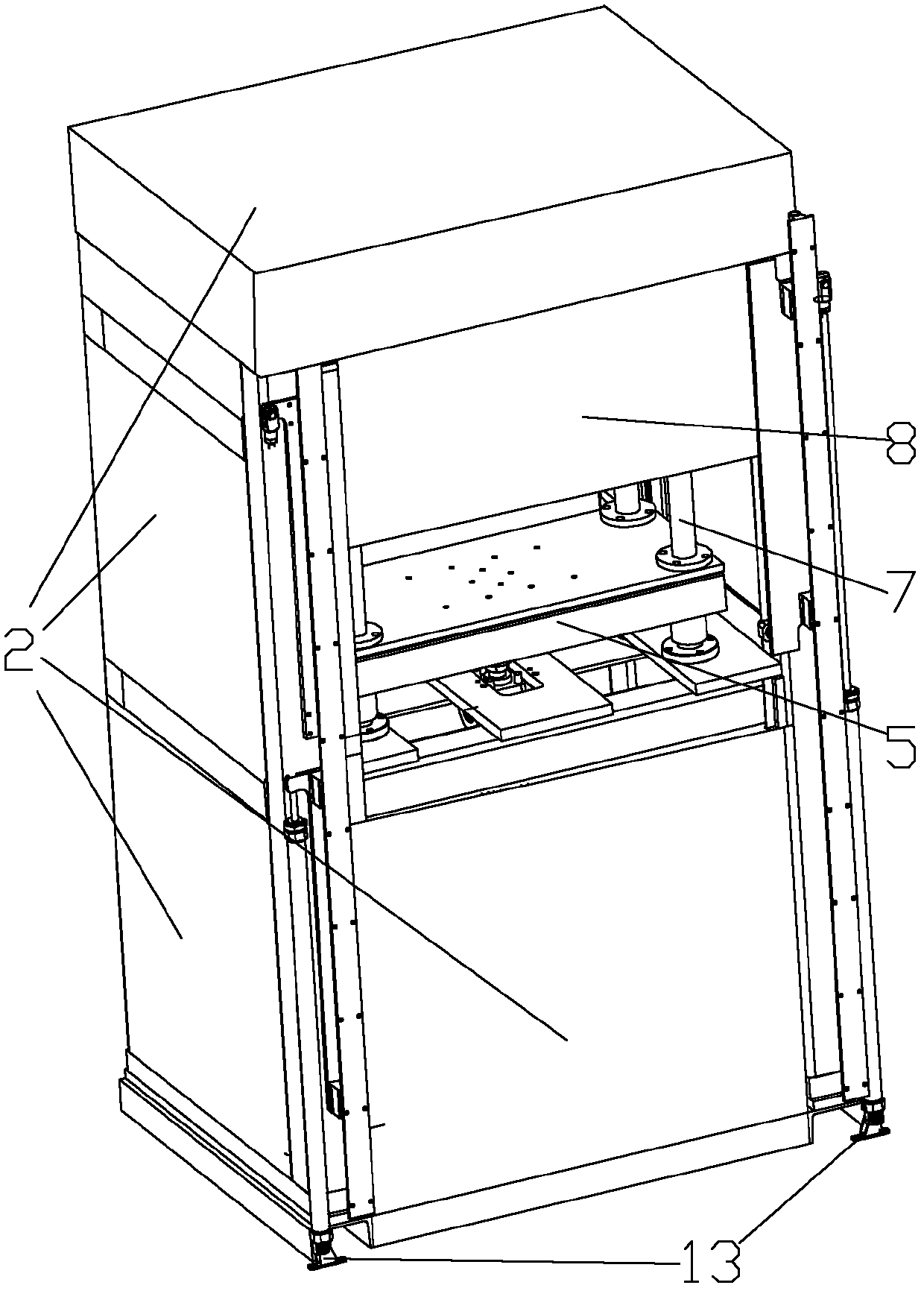

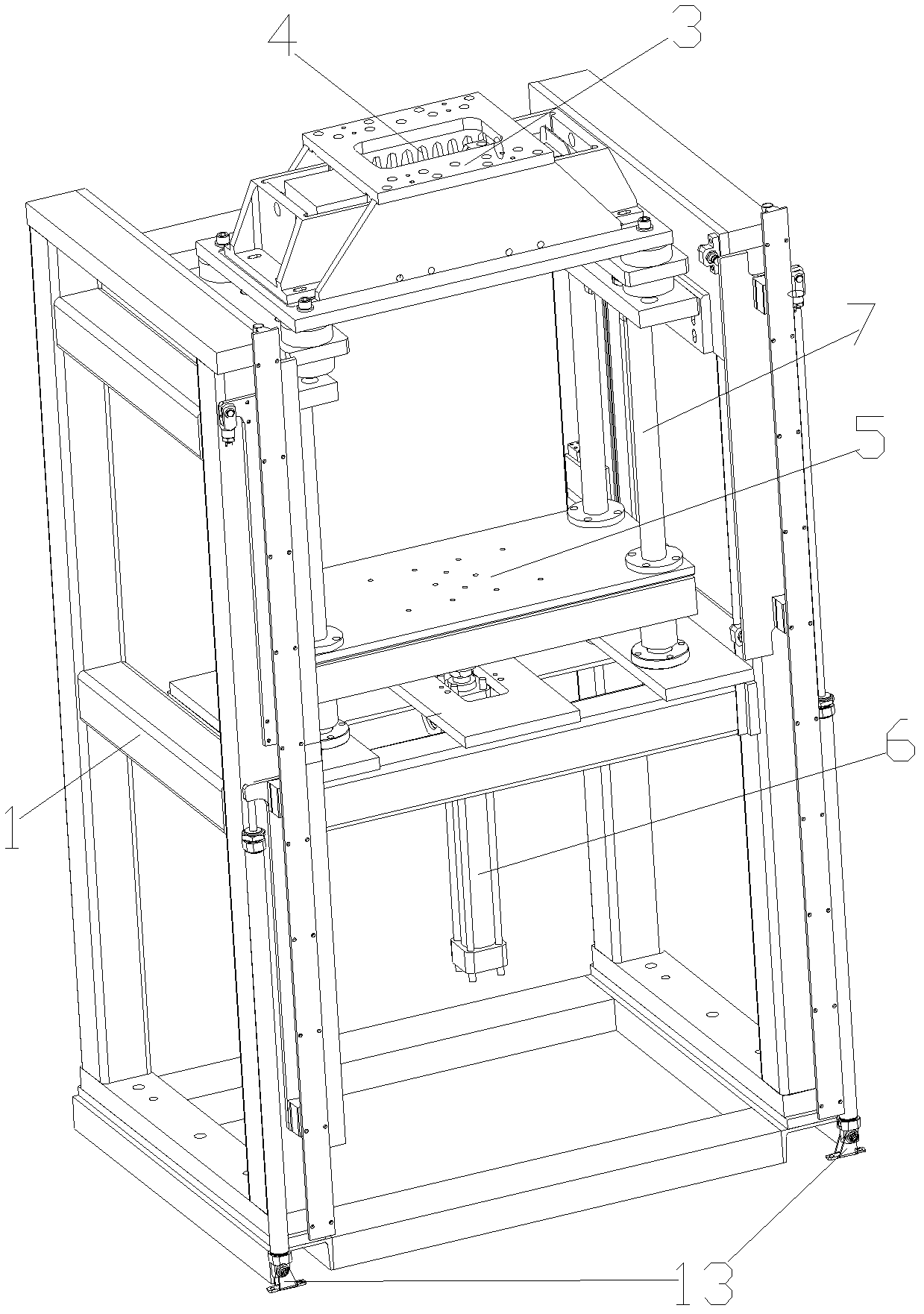

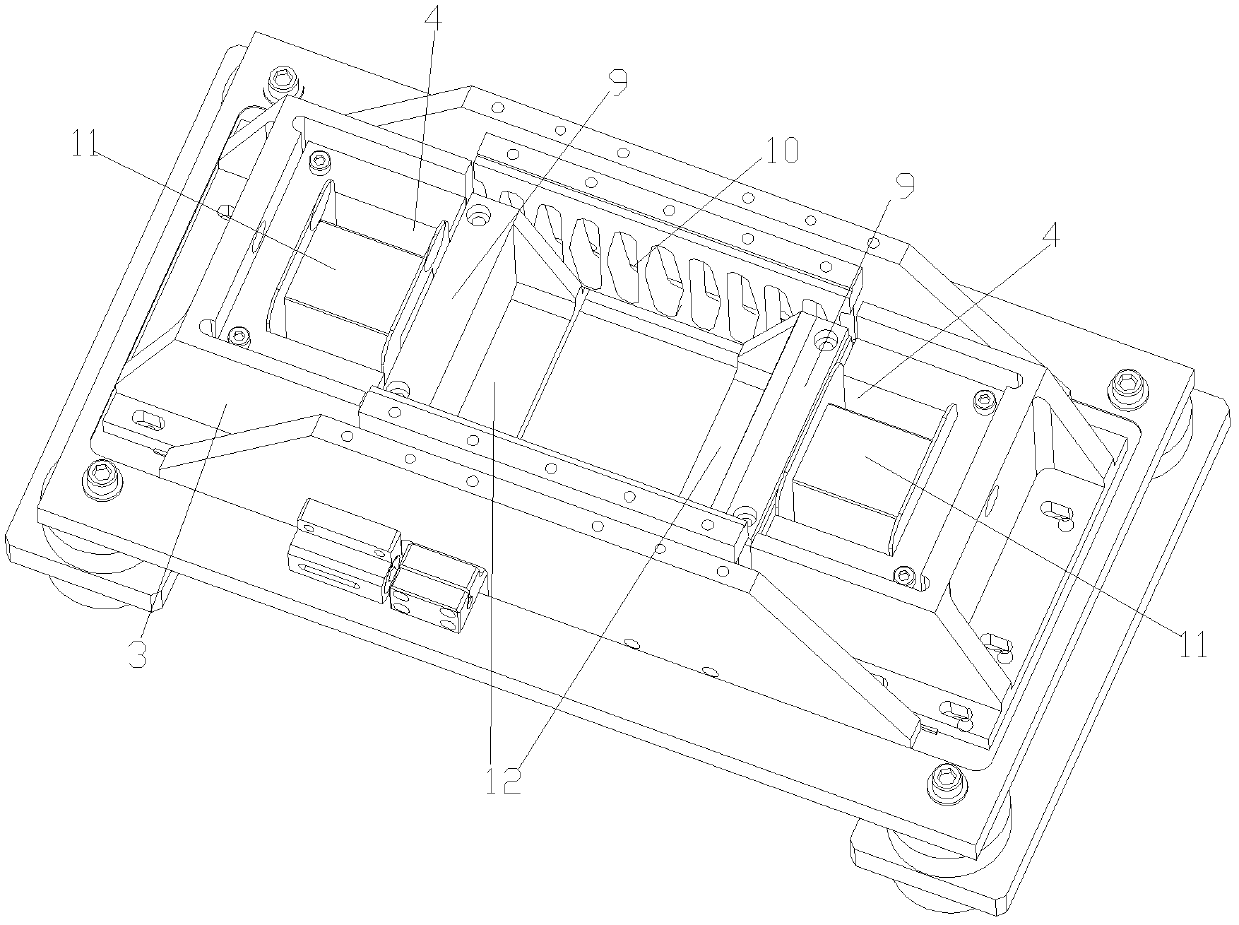

[0017] attached figure 1 , 2 , 3 are a kind of vibration friction welding machine according to the present invention, comprising equipment frame 1, the casing 2 arranged on the periphery of equipment frame 1 and the vibrating head frame 3 and lower mold lifting table 5 arranged in equipment frame 1, the machine The four walls, the bottom and the top of the shell 2 are covered with sound-absorbing materials, which reduces the noise pollution in the workshop; an automatic vertical sliding door 8 with a sound-absorbing pad is installed on the front of the shell 2, and the sliding door 8 is activated when the start switch is released. It will automatically return to ensure the safety of the operator. The vibrating head frame 3 is provided with an electromagnetic vibrating head 4; the electromagnetic vibrating head 4 is mainly composed of two vibrating armatures 9 symmetrically arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com