NCO replaced crosslinking cured joint filling material for concrete pavement

A cement pavement, cross-linking and curing technology, applied in the direction of roads, roads, pavement details, etc., to achieve the effect of low viscosity and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

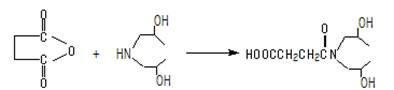

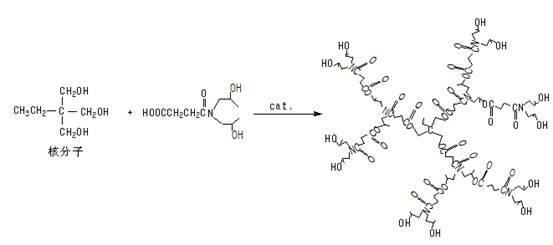

[0073] (1) Weigh 30.022 g of succinic anhydride and 39.952 g of diisopropanolamine, first dissolve diisopropanolamine in 70 mL of DMAc, pour it into a three-necked flask with a magnetic stirrer, and then add succinic anhydride Dissolve with 70 mL DMAc, then slowly drop it into the three-necked flask while stirring, add dropwise for about 1 hour, and react at room temperature for 3 hours to obtain AB 2 type monomer. In the above system, firstly add 60 mL of toluene (toluene is a water-carrying agent), add 1.916 g of trimethylolpropane as the core molecule, add 0.3 g of p-toluenesulfonic acid, and then start heating until it boils, and there is reflux in the spherical condenser tube produce. After incubating for 7 h, slowly add 15 mL of acrylic acid dropwise to the system, dropwise for about 1 hour, control the reaction temperature at 90-120°C, separate water under reflux, react for 4-6 hours, and then remove the solvent and excess excess by distillation under reduced pressure....

example 2

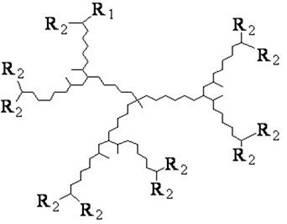

[0079] (1) Put 104 mL of divinyltriamine in a 500 mL three-necked flask, cool it in an ice-water bath, and place it under N 2 Under the protection, the mixed solution of 86 mL methyl acrylate and 200 mL methanol was slowly added dropwise with a constant pressure funnel. 2 type monomer, then distilled under reduced pressure to remove methanol, then heated to 150 °C for 4 h under reduced pressure, and stopped the reaction to obtain a viscous pale yellow amino-terminated hyperbranched compound. 60ml of toluene was added to the system as a solvent, and then 15mL of acrylic acid was slowly added dropwise to the system for about 1 hour. Solvent and excess acrylic acid gave hyperbranched polymers containing a small amount of amino groups and a large amount of -C=C at the end.

[0080] (2) 30g of polyoxypropylene glycol with molecular weight of 2000, hydroxyl value of 54-58mgKOH / g, 20g of molecular weight of 3050, hydroxyl value of 55-58mgKOH / g polyoxypropylene triol, and 15g of po...

example 3

[0085] (1) Weigh 30.022 g of succinic anhydride and 39.952 g of diisopropanolamine, first dissolve diisopropanolamine in 70 mL of DMAc, pour it into a three-necked flask with a magnetic stirrer, and then add succinic anhydride Dissolve with 70 mL DMAc, then slowly drop it into the three-necked flask while stirring, add dropwise for about 1 hour, and react at room temperature for 3 hours to obtain AB 2 type monomer. In the above system, firstly add 60 mL of toluene (toluene is a water-carrying agent), add 1.916 g of trimethylolpropane as the core molecule, add 0.3 g of p-toluenesulfonic acid, and then start heating until it boils, and there is reflux in the spherical condenser tube produce. After incubating for 7 h, slowly add 15 mL of acrylic acid dropwise to the system, dropwise for about 1 hour, control the reaction temperature at 90-120°C, separate water under reflux, react for 4-6 hours, and then remove the solvent and excess excess by distillation under reduced pressure....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com