Ribbon cutting machine

A technology of cutting machine and webbing, which is applied in the cutting of textiles, papermaking, and textile materials, etc., can solve problems such as low efficiency, and achieve the effects of improving production efficiency, saving labor costs, and facilitating adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

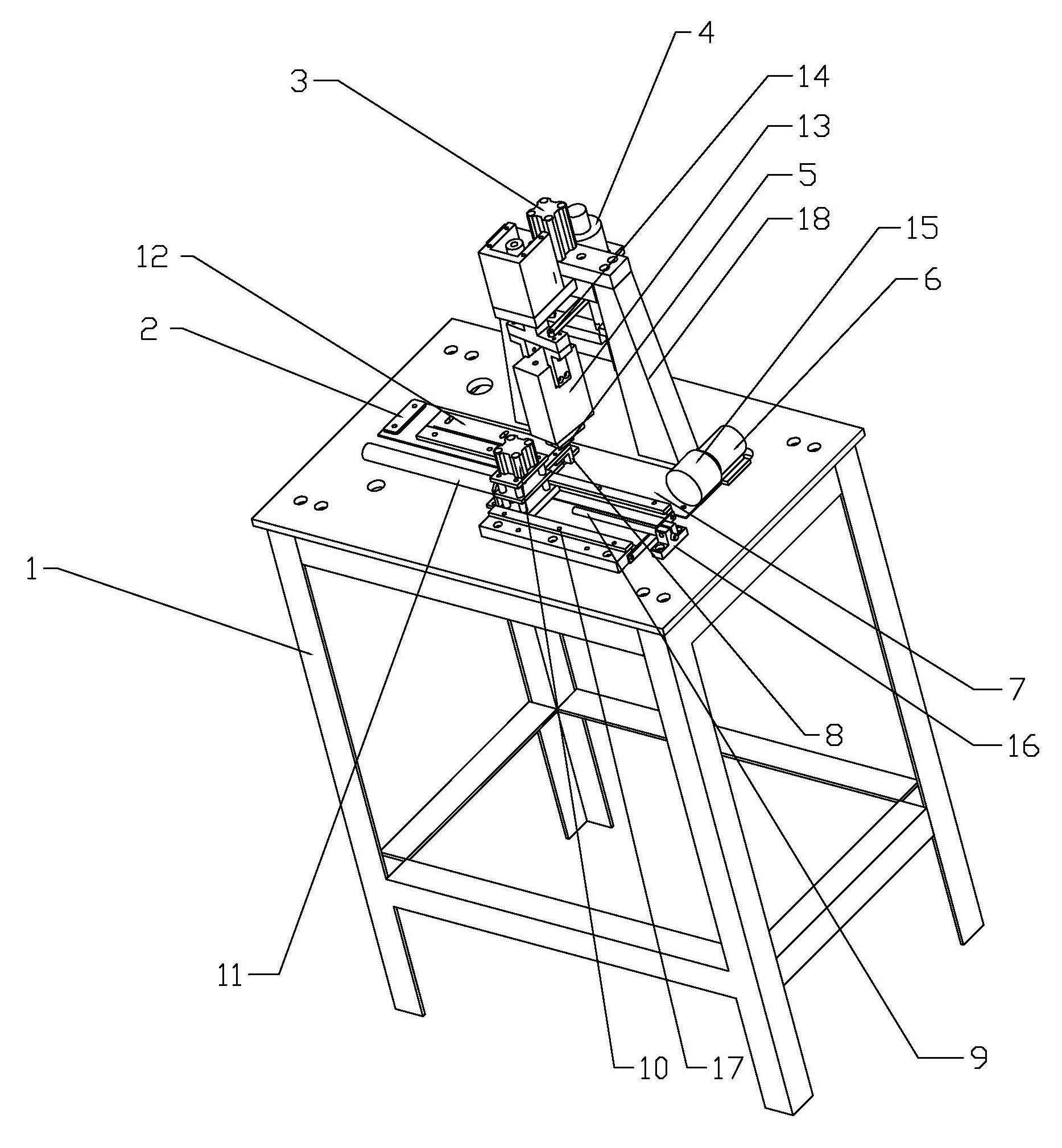

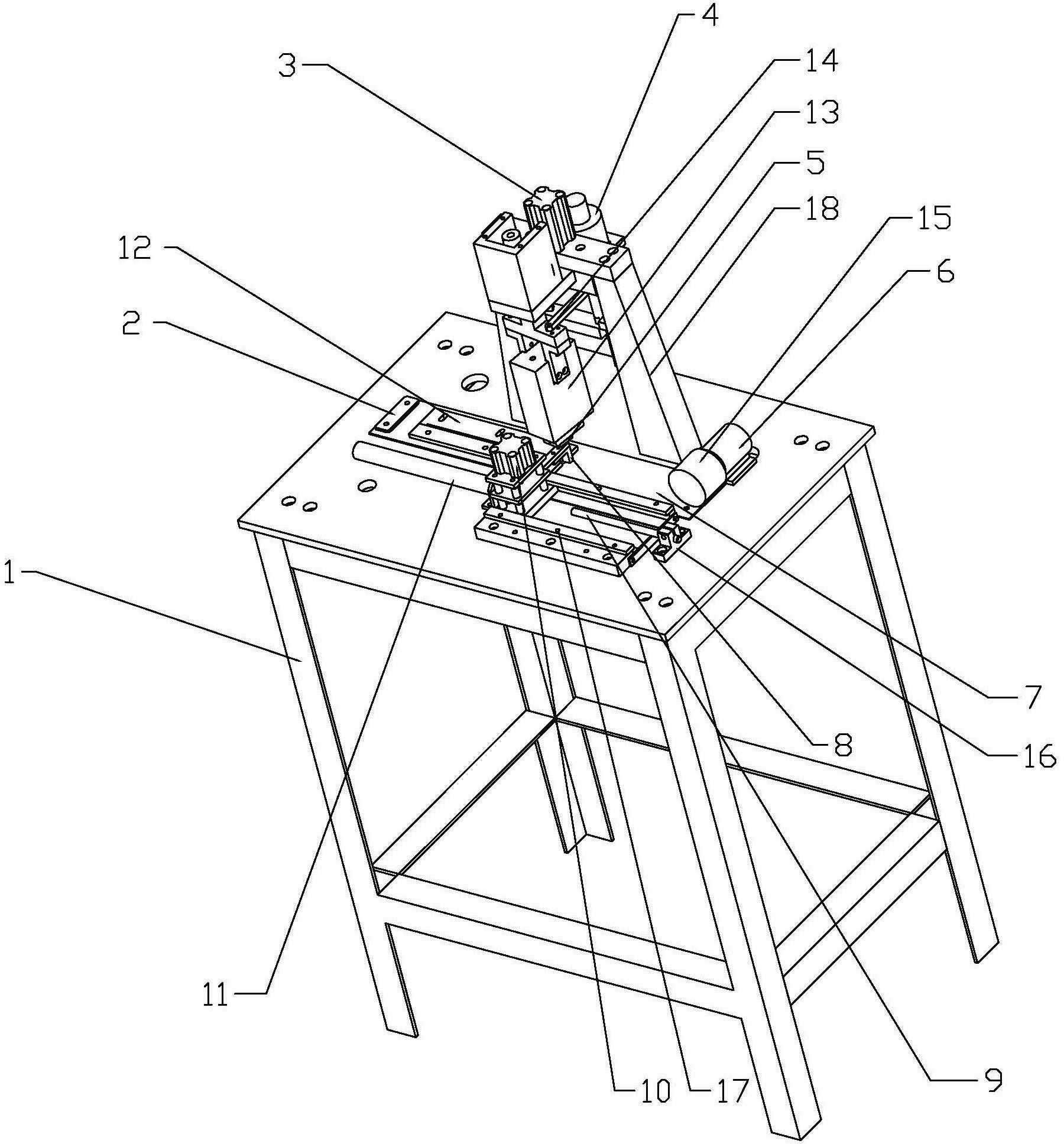

[0020] Please see attached figure 1 , the main body of the present invention is a frame 1, the frame 1 plays a supporting role, and the top surface of the frame 1 is an operating table. In the present embodiment, a support frame 18 is fixedly installed on the frame 1. In this embodiment, for a clearer description, the forward direction of the webbing is defined as the rear. In this embodiment, a rotating cylinder 4 and a cutting cylinder 3 are fixedly installed on the top of the support frame 18, and the hot-melt cutting knife is installed on the air rod of the cutting cylinder 3, and the hot-melt cutting knife is pushed up and down by the cutting cylinder 3, and the webbing Carry out cutting, in the present embodiment, the hot-melt cutting knife...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap