Recyclable anchor rod for foundation pit support and construction method thereof

A foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of large number of anchor bars, complex cable body structure, high recycling cost, etc., and achieve simple and quick disassembly and recycling process , Dismantling and recycling process is efficient and the effect of low support cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below.

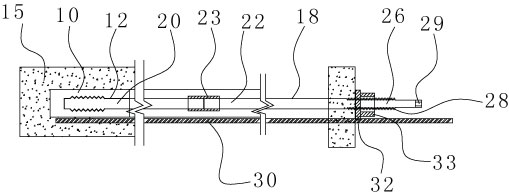

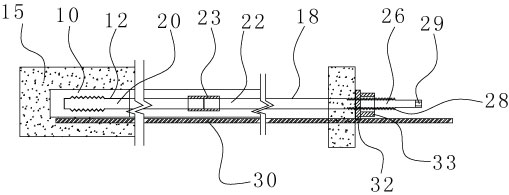

[0021] Such as figure 1 As shown, the present invention is a recoverable anchor rod for foundation pit support, which includes a concrete prefabricated part 10 and a round steel anchor rod 20, and the inside of the concrete prefabricated part 10 is provided with a hollow metal threaded sleeve 12, The front end 21 of the round steel anchor 20 is provided with an external thread and is screwed to the concrete prefabricated part 10 through the metal threaded sleeve 12 , and the tail 26 of the round steel anchor 20 is provided with a locking thread 28 .

[0022] Before installation, the round steel anchor rod 20 is put on the concrete prefabricated part 10 with anchor support threaded sleeve (metal thread sleeve 12) and sent into the anchor hole, inject cement slurry or fine stone concrete, and wait for it to solidify to form an anchor seat After 15, it can be tensioned and anchored. When disassembling,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com