Mounting structure positioned by aid of external cylindrical surface of element with non-circular section

A technology of installation structure and cylindrical surface, which is applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of inlay installation processing difficulties, difficult positioning, inconvenient disassembly, etc., and achieve reliable radial positioning, improved positioning accuracy, and accurate installation positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

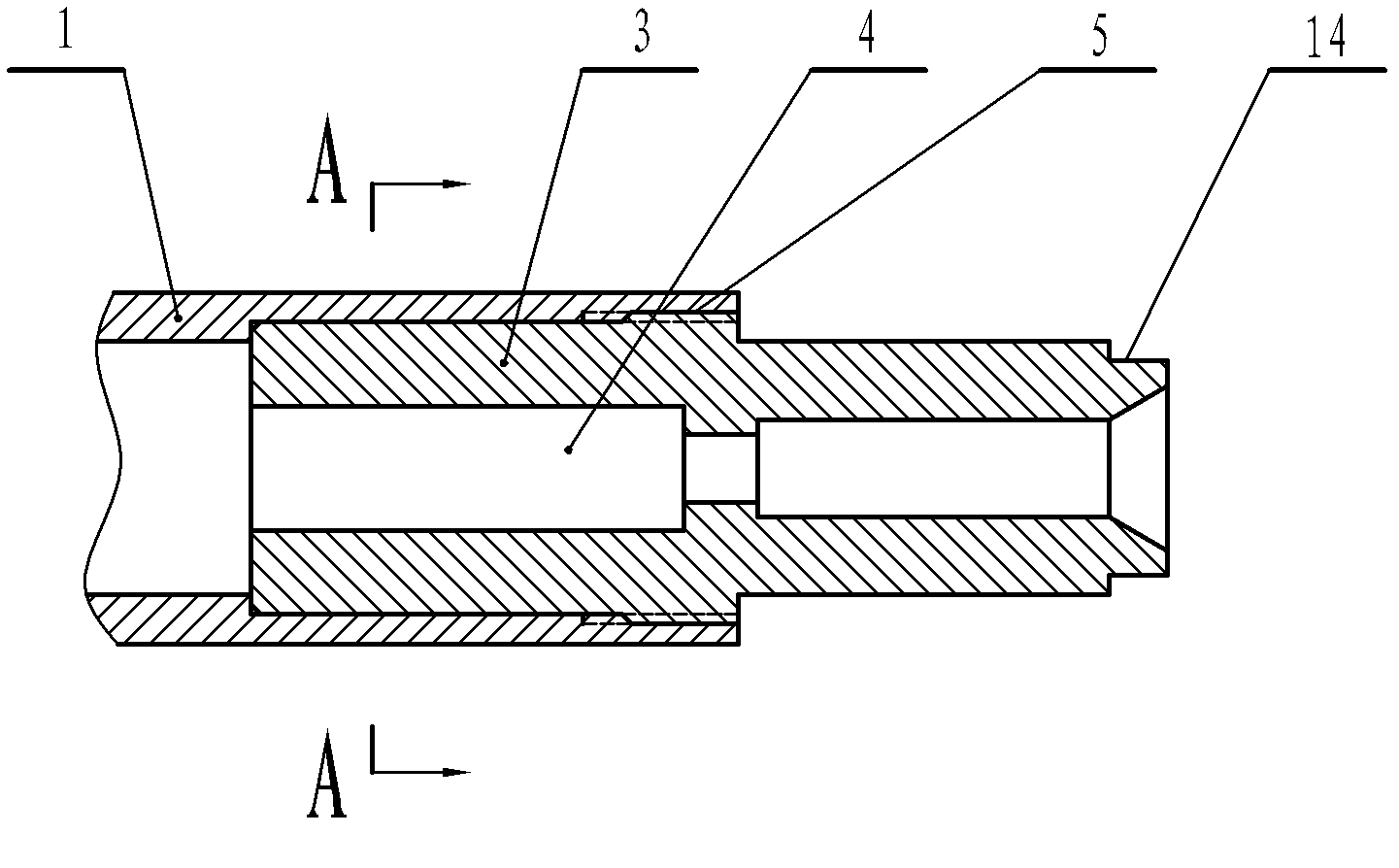

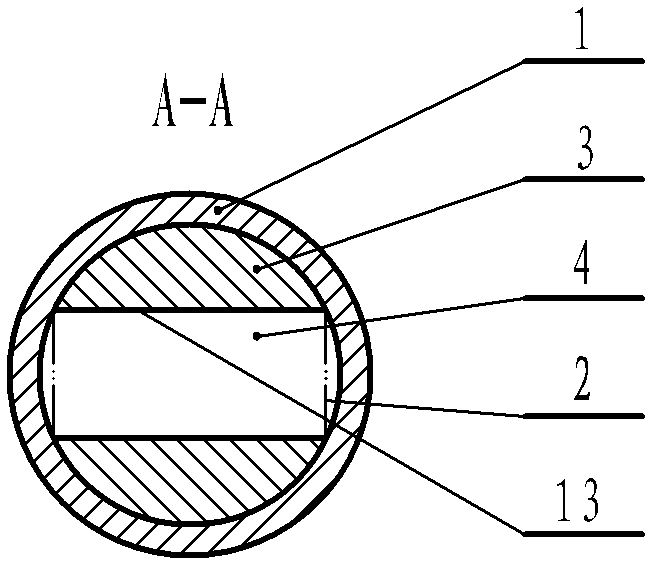

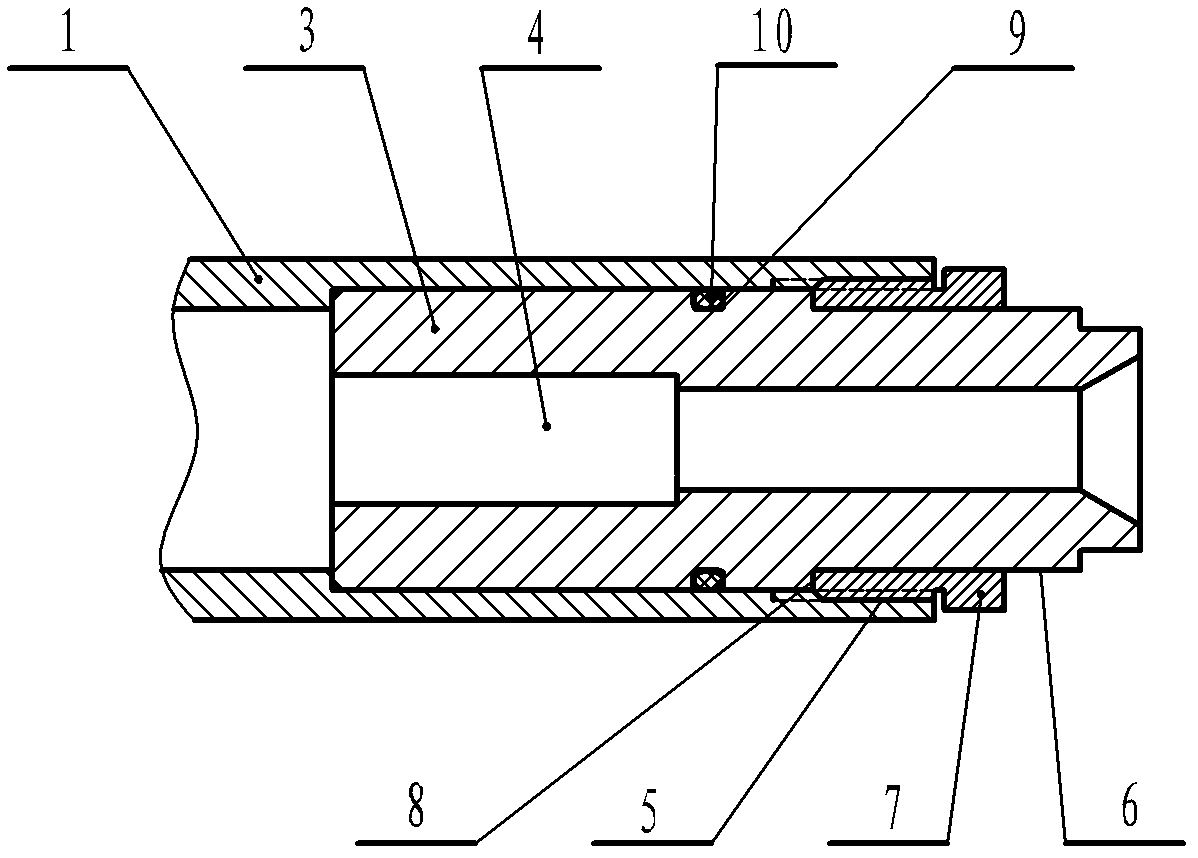

[0035] The installation structure is positioned by the circumscribed cylindrical surface of non-circular cross-section components. The schematic diagram of the cross-sectional structure is as follows: figure 1 As shown, it includes a mounting seat 1 and a non-circular section element 2, and a connecting sleeve 3 is provided. The connecting sleeve 3 is a cylindrical structure. The outer diameter of the connecting sleeve 3 is the same as the diameter of the circumscribed cylindrical surface of the non-circular section element 2. The connecting sleeve 3 One end of the groove 4 is arranged in the axial direction, the section of the groove 4 contains the section of the non-circular section element 2, the length of the groove 4 along the axial direction of the connecting sleeve 3 is less than the length of the non-circular section element 2, and the length of the connecting sleeve 3 The length is greater than the length of the groove 4, and the shape and size of the groove bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com