Direct air-cooling condenser fin

An air-cooled condenser and fin technology, which is applied in the field of fins, can solve the problems of large power consumption of fans and can not meet the requirements of users for energy saving, and achieve the effects of reducing energy consumption, small resistance, and reducing air side resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

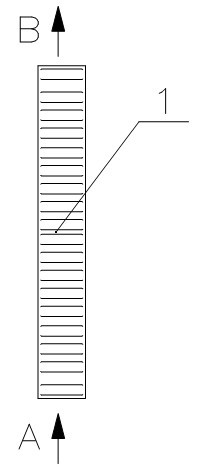

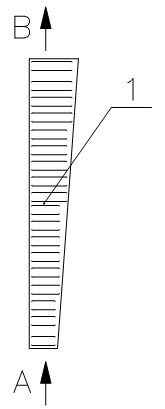

[0020] Such as figure 2 as shown, figure 2 It is a cross-sectional schematic diagram of Embodiment 1 of the present invention. Depend on figure 2 It can be seen that the fins of the direct air-cooled condenser of the present invention have a cross-sectional shape of a right-angled trapezoid. The cross section of the fin 1 is long and thin, the fin 1 is in a serpentine shape along the longitudinal direction, and the material of the fin 1 is aluminum or aluminum alloy. The cross-sectional shape of the fin 1 is a right-angled trapezoid, and its size increases from small to large along the air flow direction, and the width of the front end of the cross section facing the air flow is smaller than the width of the rear end.

[0021] In Embodiment 1, the length dimension of the cross section of the fin 1 is 180-285mm, the width dimension of the front end is 16-20mm, and the width dimension of the rear end is 19-26mm. .

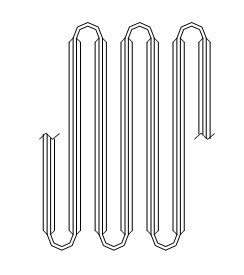

[0022] image 3 It is the serpentine curved shape of t...

Embodiment 2

[0025] Figure 4 It is a cross-sectional schematic diagram of embodiment 2 of the present invention. Depend on Figure 4 It can be seen that the present invention is a direct air-cooled condenser fin, the fin 1 has an isosceles trapezoidal cross-sectional shape, and the length of the fin 1 along the direction of the base pipe is a serpentine curved shape; the size of the fin 1 is similar to that of the first embodiment. The difference between Embodiment 2 and Embodiment 1 is mainly in the shape of the fins 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com