Heat exchange base tube for direct air-cooling condenser

A technology of air-cooled condenser and base pipe, which is applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., which can solve the problems of high power consumption of fans and failure to meet the requirements of users for energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

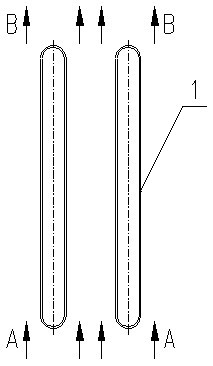

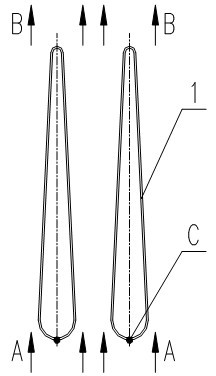

[0019] Such as figure 2 as shown, figure 2 It is a cross-sectional schematic diagram of embodiment 1 of the present invention. Depend on figure 2 It can be seen that, in the heat exchange base pipe of the direct air-cooled condenser of the present invention, the cross section of the heat exchange base pipe 1 is slender, the two ends of the cross section are arc-shaped or approximately arc-shaped, and the sides are planes. The cross-sectional shape of the base pipe 1 is wedge-shaped, and its width dimension changes from large to small along the air flow direction, and the front end width dimension of the cross section facing the air flow is larger than the rear end width dimension. The heat exchange base pipe 1 is formed by a steel-aluminum composite material coated with aluminum on one side or a steel plate coated on one side with high frequency welding, and the welding seam C is at the end.

[0020] In embodiment 1, the length dimension of the cross section of the heat ...

Embodiment 2

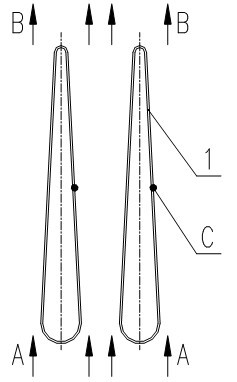

[0023] image 3 It is a cross-sectional schematic diagram of embodiment 2 of the present invention. Depend on image 3 It can be seen that the heat exchange base pipe of a direct air-cooled condenser in the present invention has a wedge-shaped cross-sectional shape, and the position of the weld C is on the side; the size of the heat exchange base pipe 1 is similar to that of Example 1. The difference between Embodiment 2 and Embodiment 1 is mainly that the positions of the weld seams are different.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length dimension | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com