Mine clearance vehicle

A demining vehicle and turntable technology, which is applied in defense devices, manipulators, offensive equipment, etc., can solve the problems of incomplete demining and left unexploded mines, and achieve the effects of high degree of automation, rapid detection, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

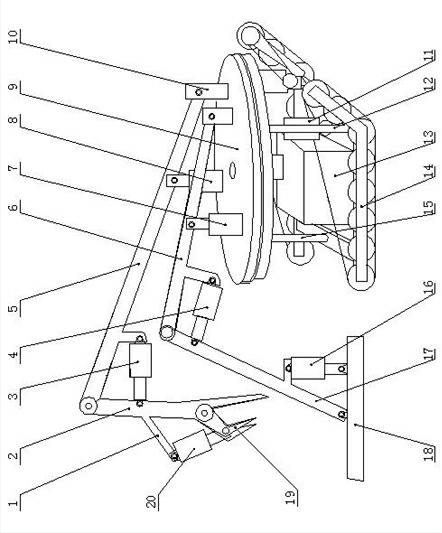

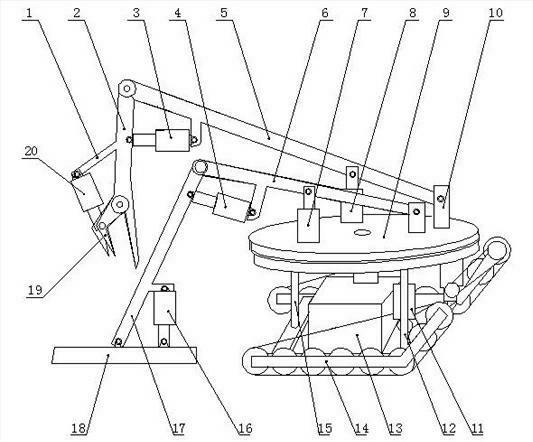

[0010] Example: such as figure 1 As shown, the mine removal vehicle includes a mine removal arm, a mine detection arm, a turntable 9 and a turntable seat 11 for supporting the mine removal arm and the mine detection arm. The front frame 17 and the rear frame 13 are arranged in a triangle, and the hydraulic cylinder 15 is fixed in the cavity surrounded by them. The turntable seat 11 is fixed on the front frame 17 and the rear frame 13 upper ends, and the turntable seat 11 is fixed at the bottom of the turntable motor 14, and the turntable motor 14 rotating shafts stretch out the upper end of the turntable seat 11, a turntable 9 is installed at the upper end of the turntable motor 14 turning shafts, and a mine removal arm and a mine detection arm are installed on the upper end of the turntable 9, and the mine removal arm is composed of the mine removal forearm 2 and the mine removal rear arm 5 Composition, is provided with grasping piece 21 at the front part of demining forearm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com