Method for screening iron cores of electromagnetic gyroscope

A technology of iron core and gyroscope, which is applied in the direction of measuring devices, instruments, etc., can solve the problems of reduced production efficiency, increased production cost, and increased production cost, and achieve the effects of reducing labor intensity, improving performance, and improving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

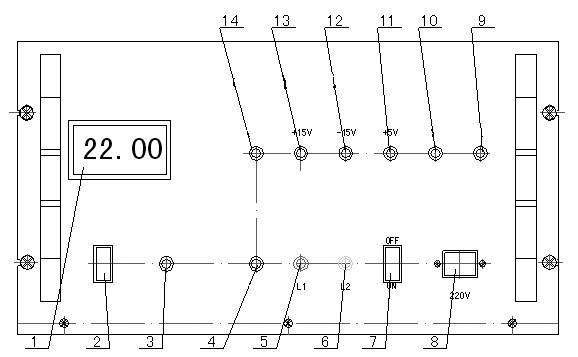

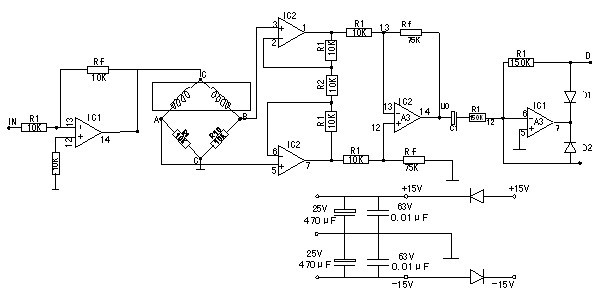

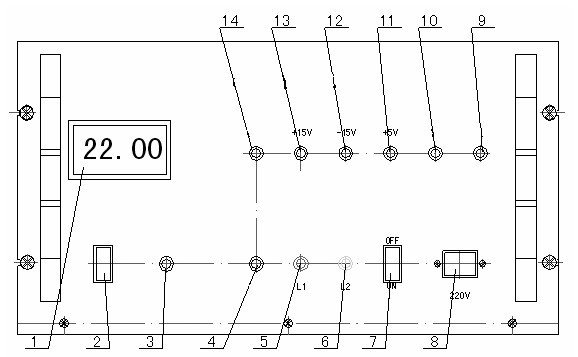

[0018] Such as figure 1 As shown, the method for electromagnetic gyroscope iron core screening includes at least: a detection circuit 15, a housing 16, a measured iron core jack 3 and a standard iron core jack 4 are arranged on the housing 16, and the tested iron core jack 3 and the standard iron core jack 4 are electrically connected with the detection circuit 15, the standard iron core is inserted into the standard iron core jack 4 on the panel, the tested iron core is inserted into the tested iron core jack 3 on the panel, and the detection circuit 15 will The difference between the measured iron core and the standard iron core is directly on the display head 1.

[0019] The housing 16 has an output waveform test hole 14, an error voltage test hole 10, a +5V test hole 11, a -15V test hole 12, a +15V test hole 13, a high-voltage power supply indicator light 5, a low-voltage power supply indicator light 6, a power switch 7, Power socket 8, ground jack 9. Before screening, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com