Color difference meter assessment method for pork color

A colorimeter and color technology, applied in standardization and food application fields, can solve problems such as differences and different measurement conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

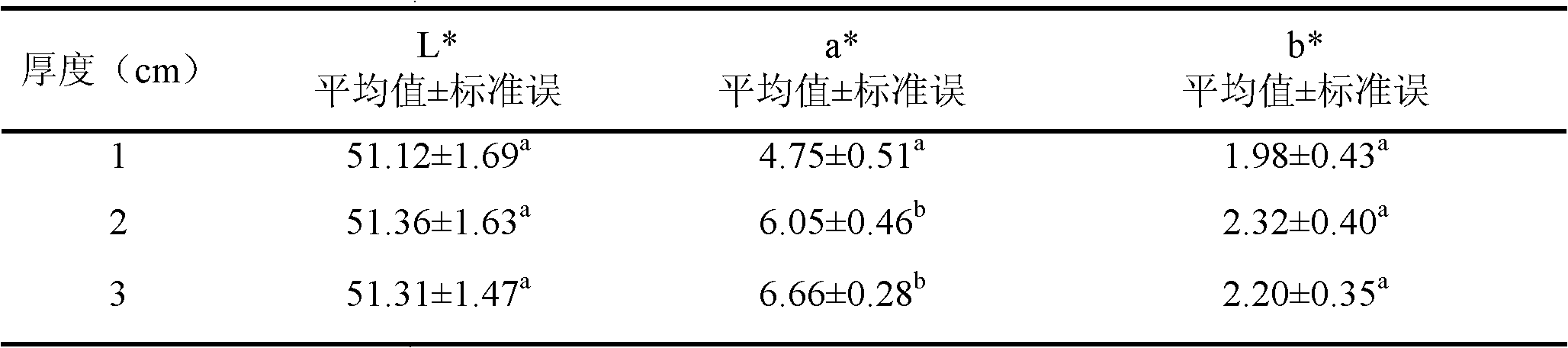

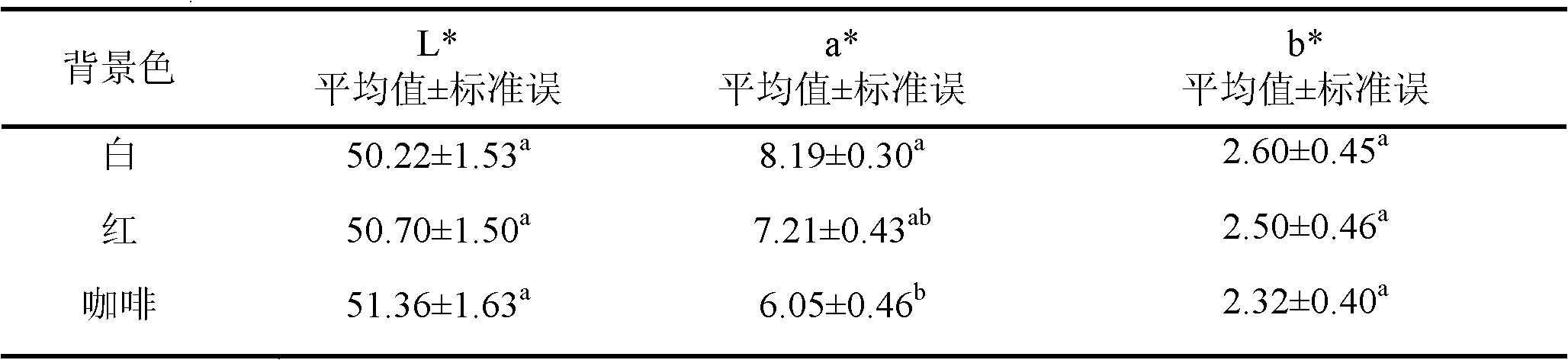

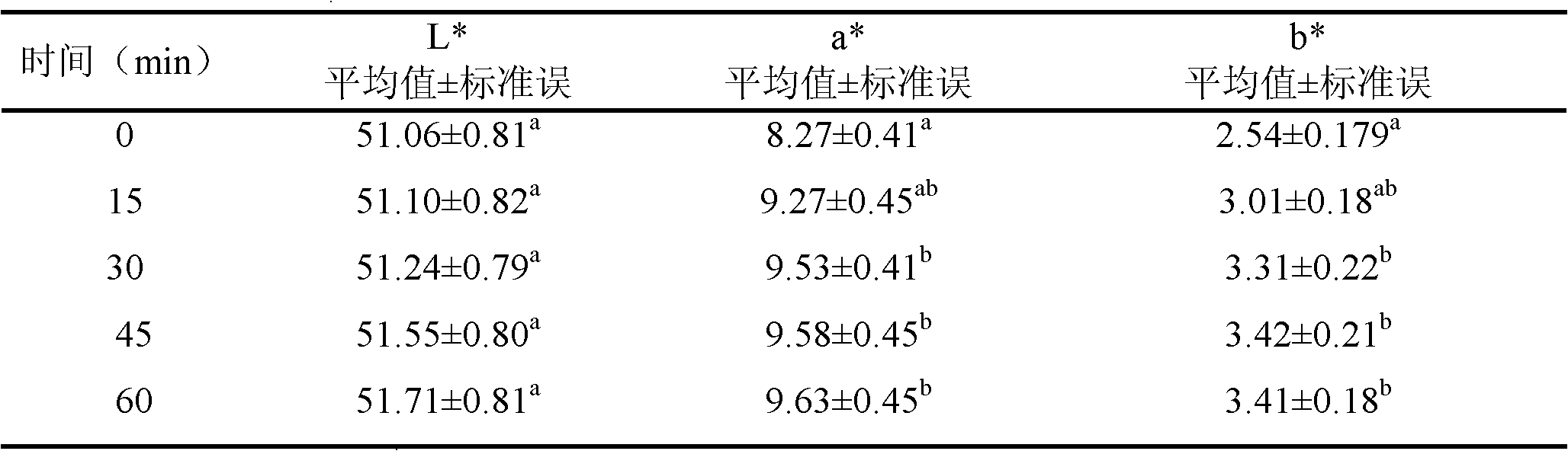

[0013] 1. Comparison of meat sample thickness

[0014] Take the longissimus dorsi muscle at the junction of pig thoracolumbar vertebrae (take the longissimus dorsi 20-30cm backward from the penultimate 3rd to 4th thoracic vertebrae) in the same piece of pork that has been sufficiently cooled at an ambient temperature of 0-4°C, respectively, along the vertical direction of the muscle. Take meat samples with a thickness of 1cm, 2cm and 3cm (5 repetitions for each thickness), place the cut pieces of meat flat on a red plastic plate (new cut side up), and cover with a single layer of colorless and transparent ordinary plastic wrap ( Oxygen transmission rate: 14483cm 3 / (m 2 .24h.atm), carbon dioxide transmission rate: 63683cm 3 / (m 2 .24h.atm), water vapor transmission rate: 54g / m 2 .24h) Wrap the meat pieces and place them at 0-4°C for 30 minutes to develop color. Calibrate the color difference meter before measuring the color difference. The specific operation is: first tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com