Buffering element and bonding method for flip-chip soft film using the same

A buffer element and bonding method technology, applied in the field of buffer elements, can solve problems such as insufficient thermal expansion of flip-chip soft film, too large, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The detailed features and advantages of the present disclosure are described in detail below in the embodiments, the content of which is sufficient for any person familiar with the relevant art to understand the technical content of the present disclosure and implement it accordingly, and according to the contents disclosed in this specification, claims and drawings, Objects and advantages related to the present disclosure can be easily understood by anyone skilled in the art.

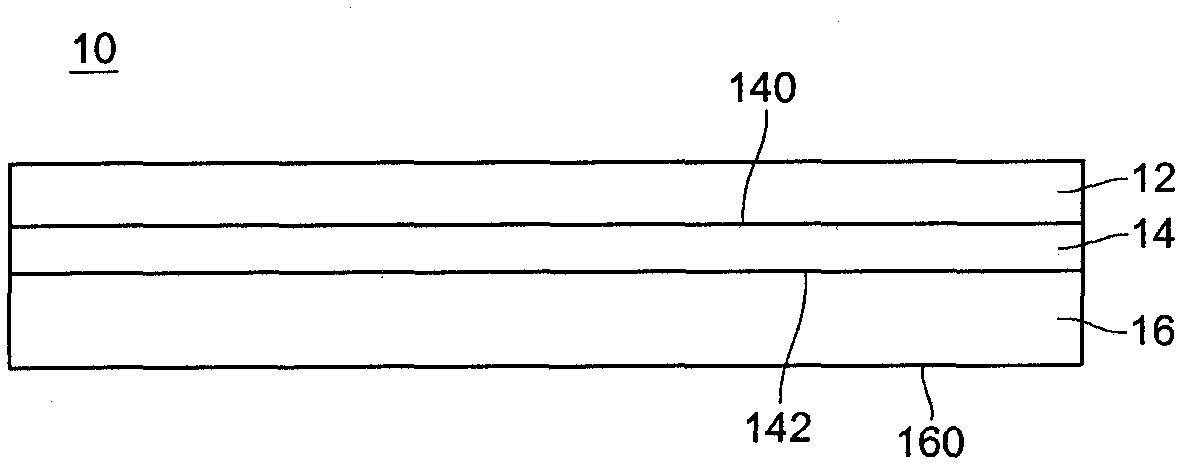

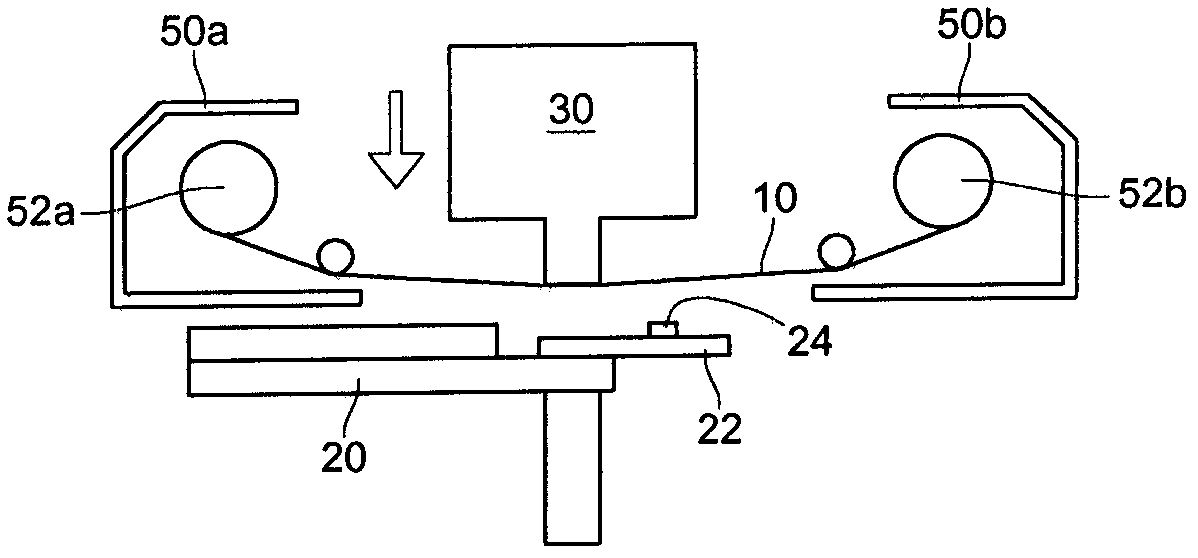

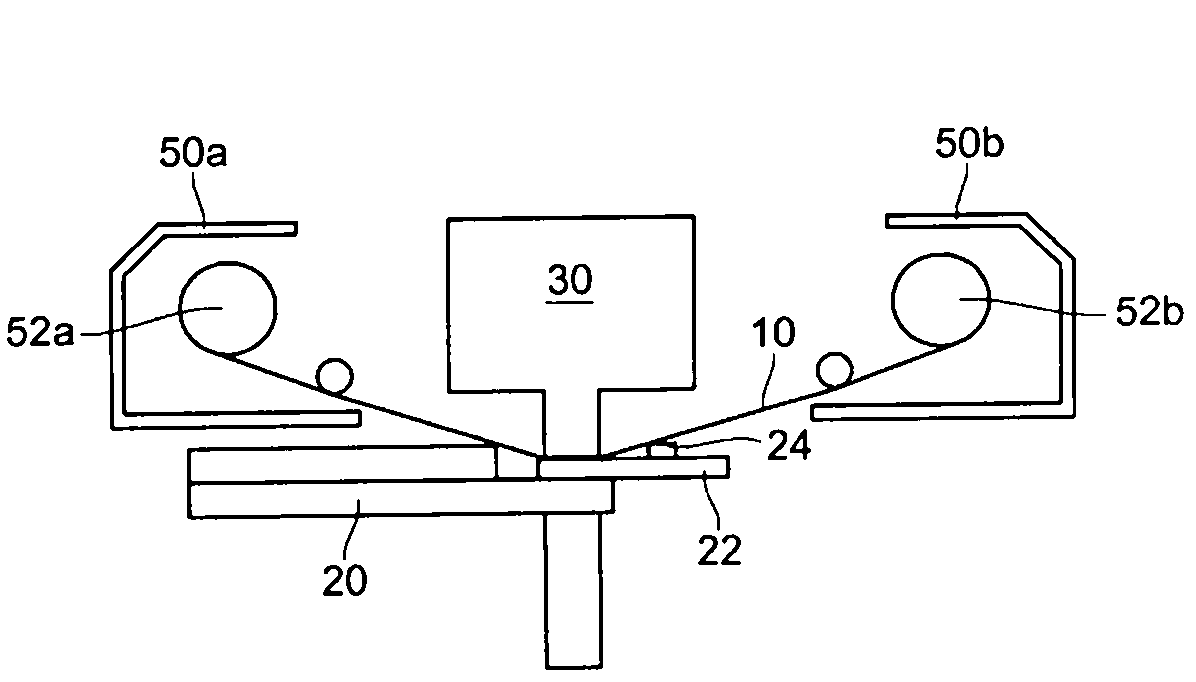

[0040] First, please refer to figure 1 , which is a structural schematic diagram of a buffer element according to an embodiment of the present disclosure. The buffer sheet 10 is suitable for a chip on film process. please match Figure 2A read. from Figure 2A It can be seen that the cushioning element 10 is wound on the rollers 52a, 52b in the Flip-chip soft film process, and the rollers 52a, 52b are respectively arranged in the cassettes (Buffer Sheet Cassette) 50a, 50b on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap