Method for solidifying lead-acid battery plate

A technology of lead-acid battery and curing method, which is applied in the direction of lead-acid battery electrodes, etc., and can solve the problems of reducing the performance of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

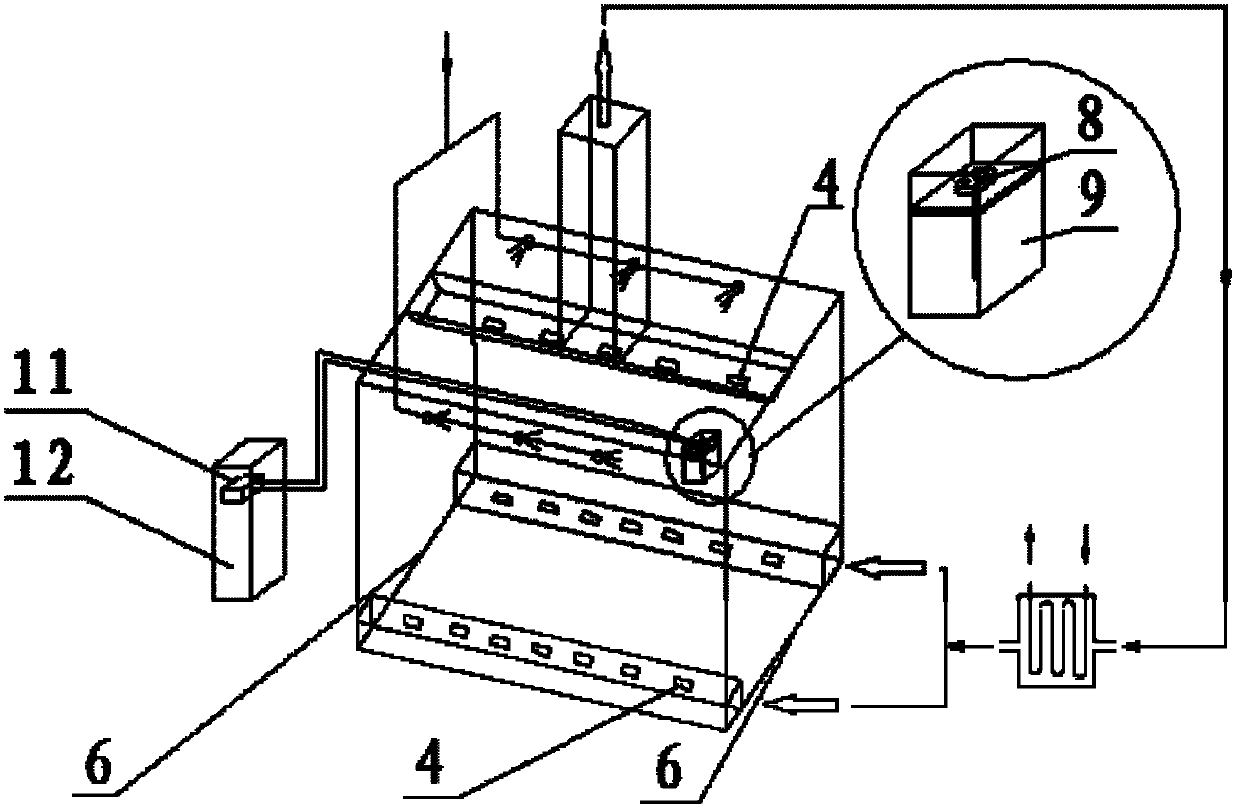

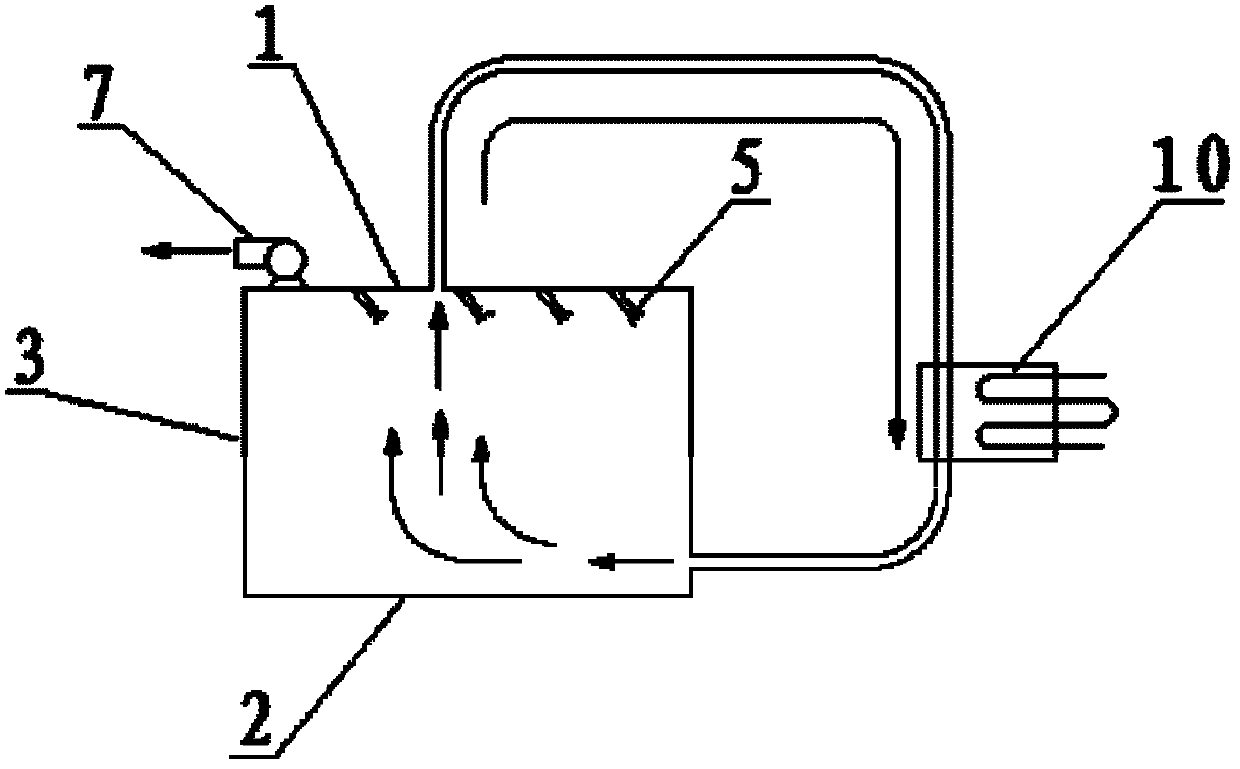

[0104] According to the technical parameters shown in Table 5, put the electrode plate filled with lead paste on the figure 1 and figure 2 In the curing room shown, the curing operation is carried out to obtain the lead-acid battery plate. Then assemble the pole plates into a 12V100Ah storage battery, and test the performance of the pole plates and the battery through the GB5008-2005 standard test method.

[0105] The curing technical parameter that table 5 embodiment 1 provides

[0106]

[0107]

Embodiment 2

[0109] According to the technical parameters shown in Table 6, put the electrode plate filled with lead paste on the figure 1 and figure 2 In the curing room shown, the curing operation is carried out to obtain the lead-acid battery plate. Then assemble the pole plates into a 12V100Ah storage battery, and test the performance of the pole plates and the battery through the GB5008-2005 standard test method.

[0110] The curing technical parameter that table 6 embodiment 2 provides

[0111]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com