Multifunctional royal jelly collecting machine

A pulp extractor and multi-functional technology, applied in application, beekeeping, animal husbandry, etc., can solve the problems of labor and working hours, cumbersomeness, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

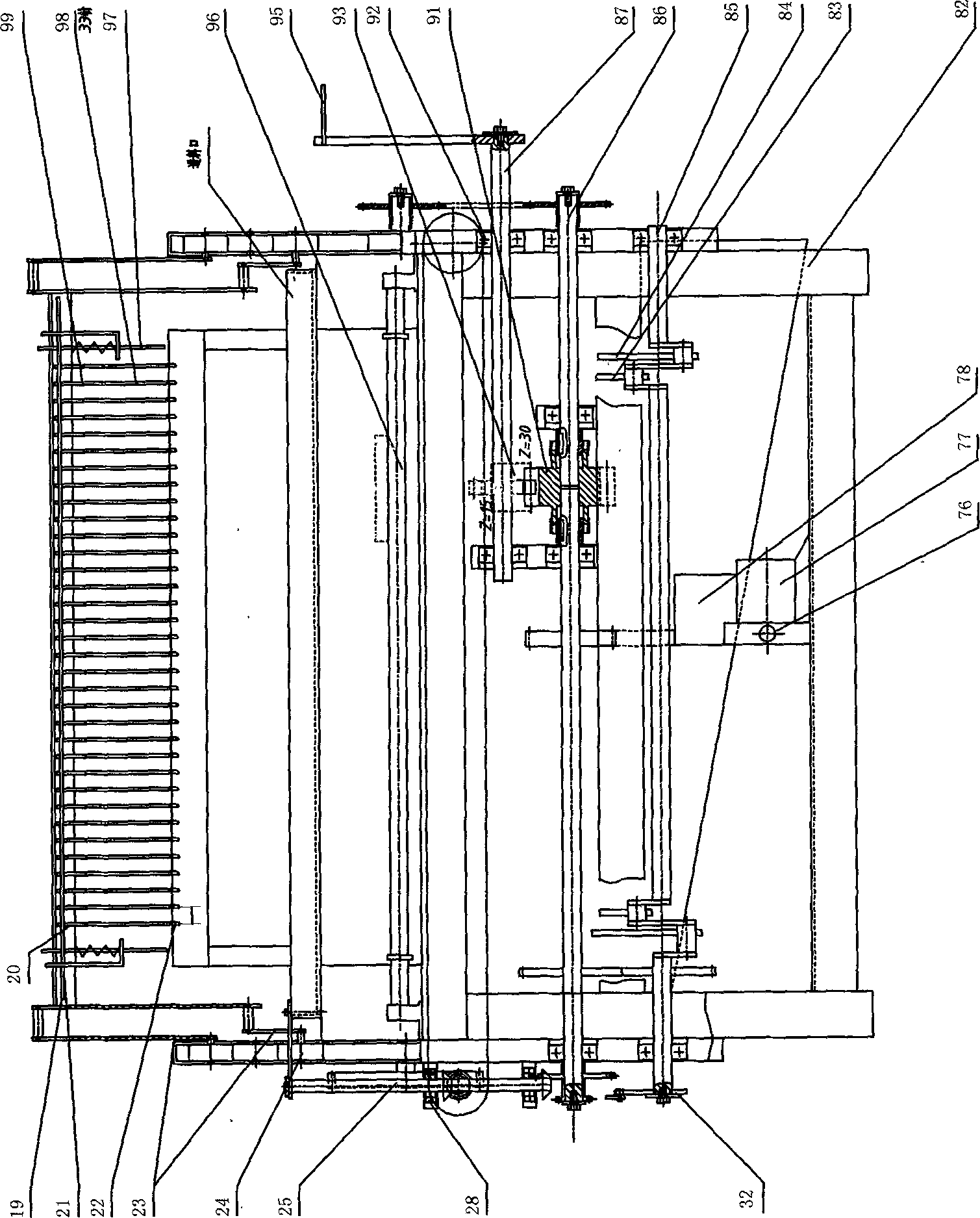

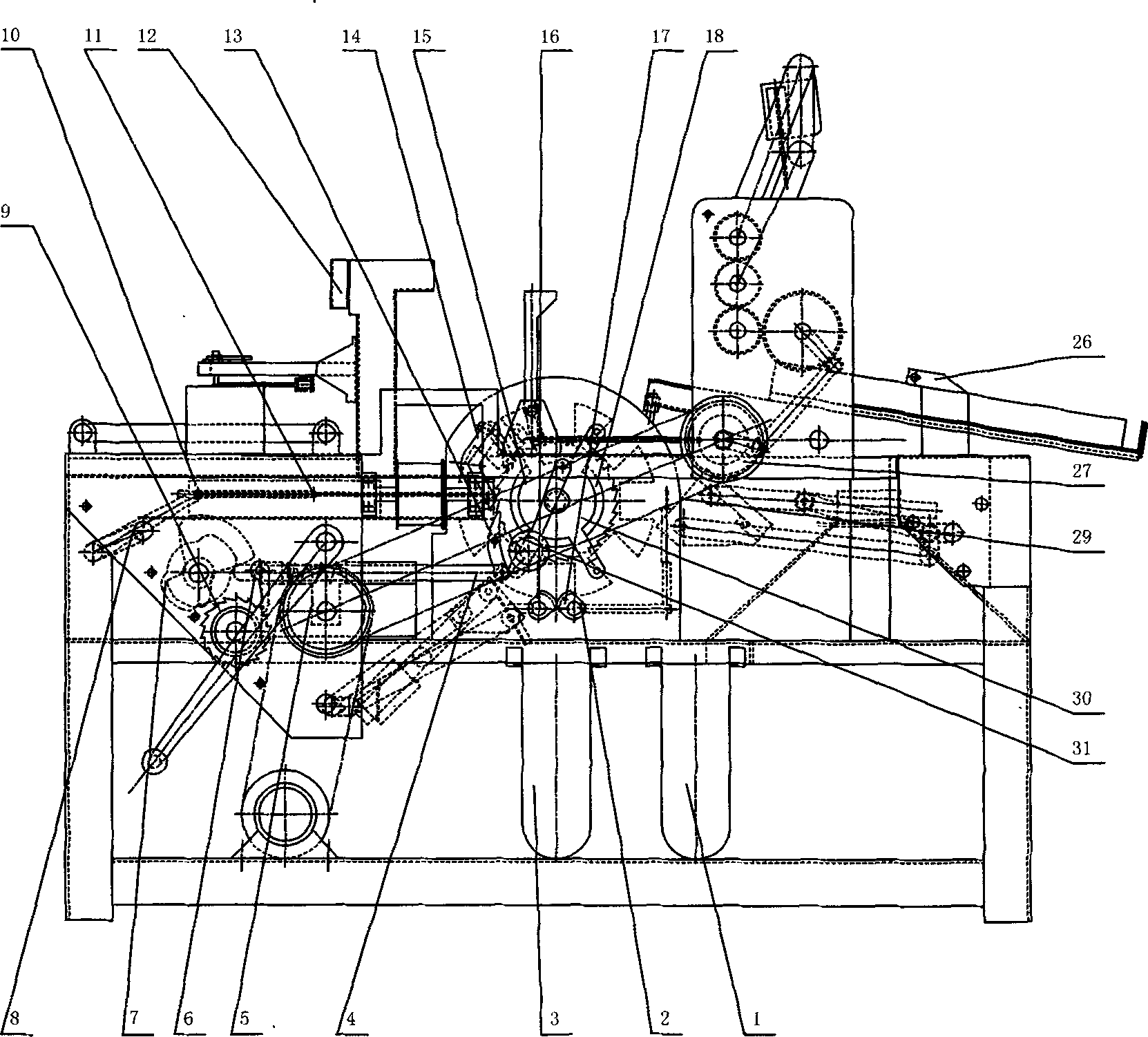

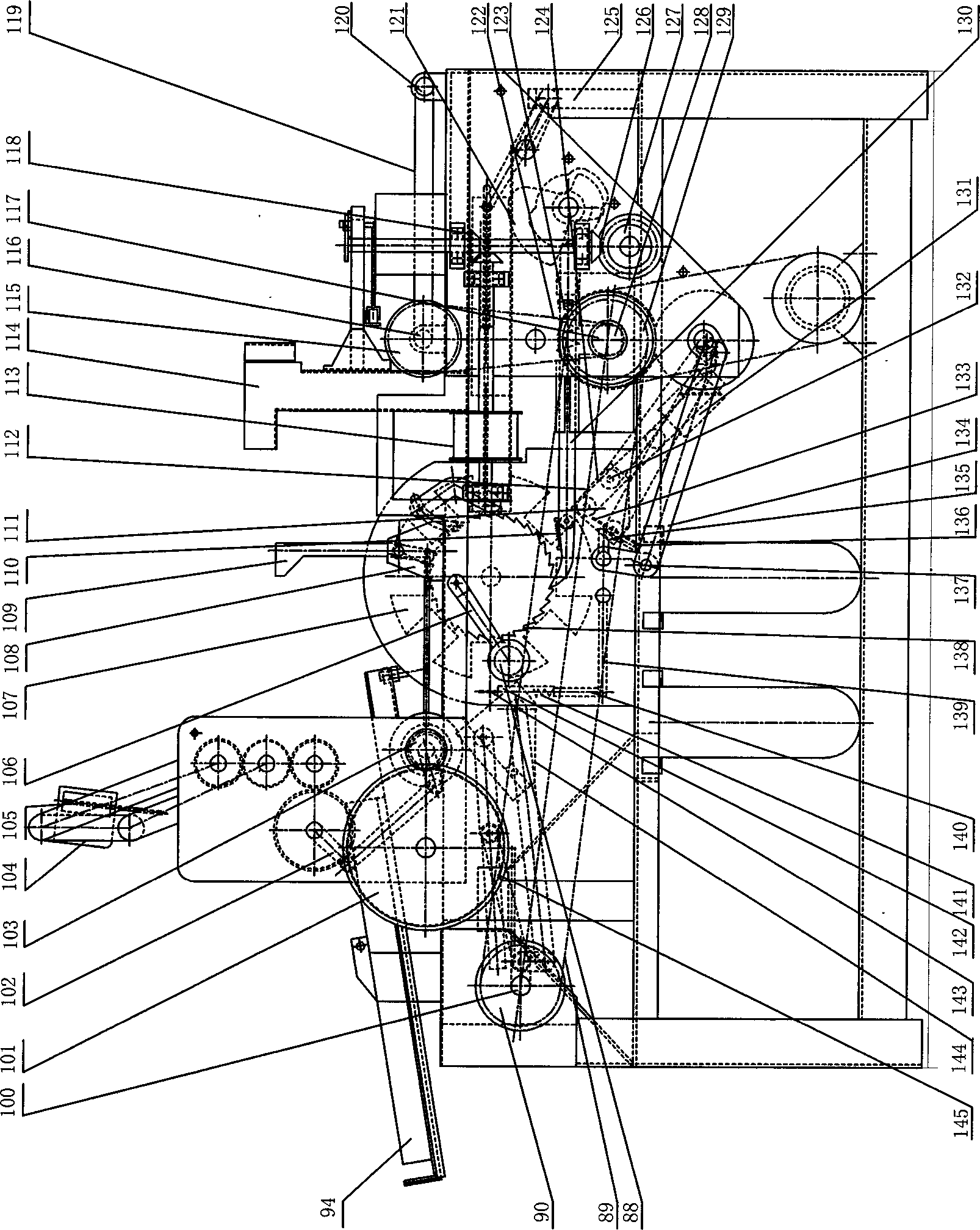

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0026] Figure 1 to Figure 6 It is a preferred version of the present invention, which shows a multifunctional pulp extractor, including a feeding mechanism, a cutting room wall mechanism, a picking larvae mechanism, a two-way scraping mechanism, a transplanting larvae mechanism and a honeycomb displacement mechanism, according to the royal jelly production operating procedure. They are arranged successively around the center dial, and the gear lever controls the six mechanisms to coordinate their work. Through the transmission device, the working procedures of each step and the working position (angle) of the royal jelly strips are accurately positioned to complete the royal jelly strips from feeding to discharging. Various tasks of materials.

[0027] 1. Power transmission and workmanship procedures

[0028] 1. Feeding mechanism

[0029] (1) Feeding mechanism: it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com