A slide rail positioning return device

一种滑轨、内滑轨的技术,应用在家里用具、家具零件、抽屉等方向,能够解决使用寿命降低等问题,达到提升使用寿命、提高荷重能力、减少机构动作不顺的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

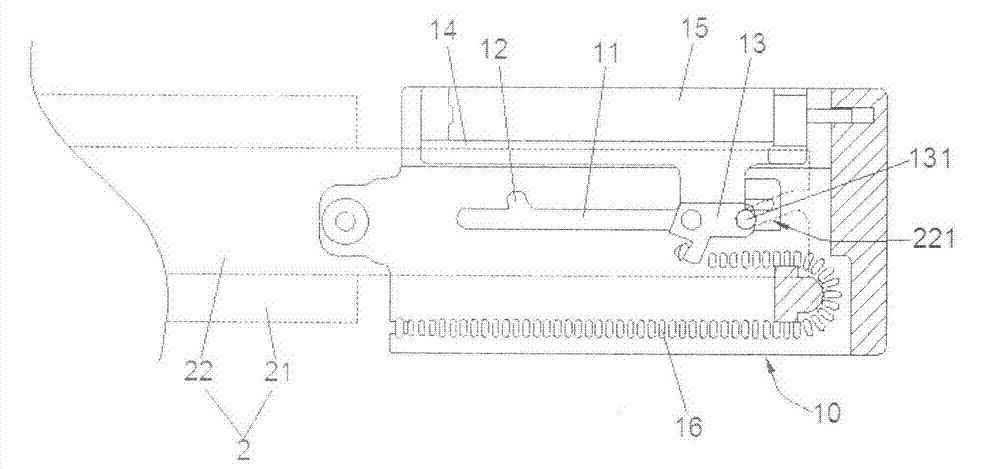

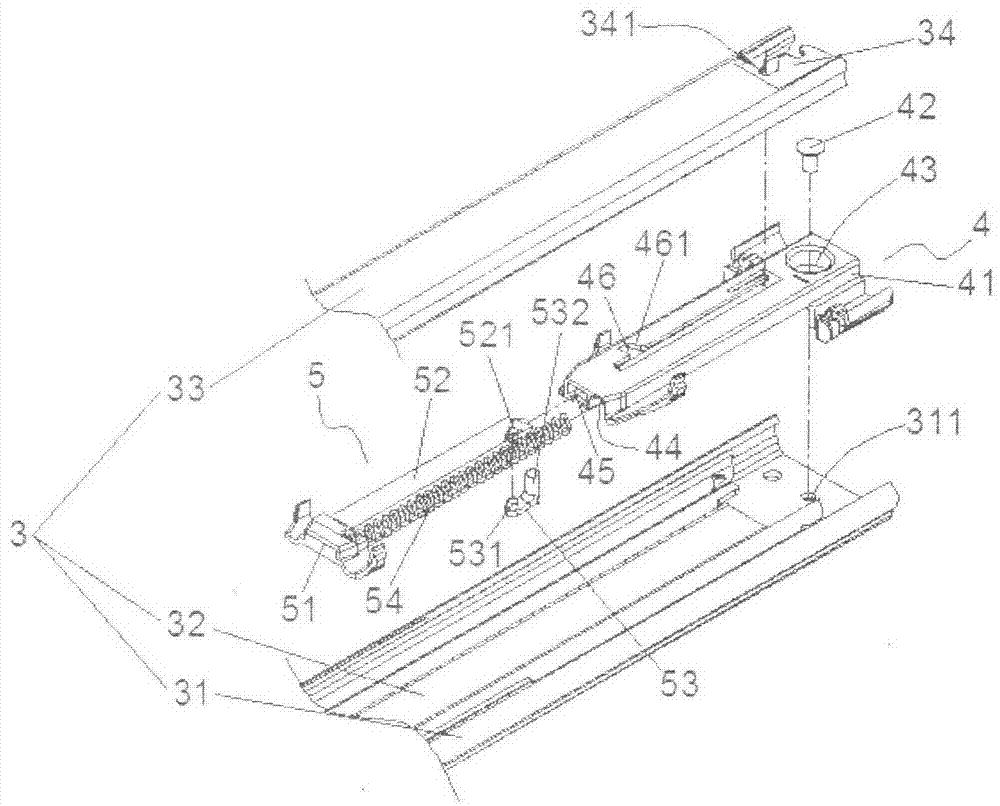

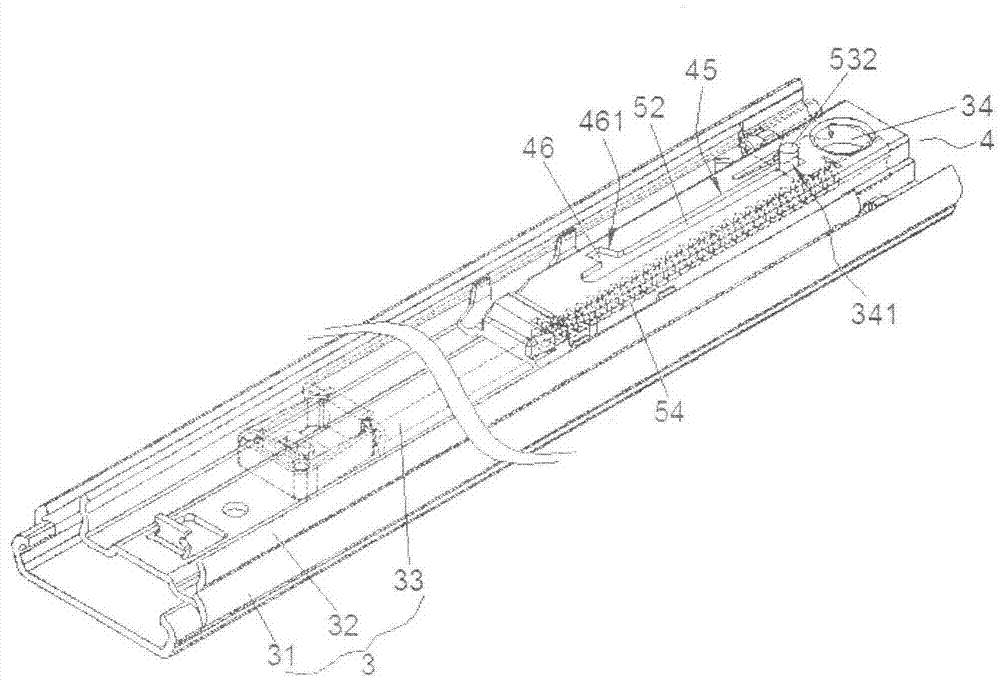

[0025] like figure 2 , image 3 Shown is a slide rail positioning return device, including:

[0026] A slide rail mechanism 3, the slide rail mechanism 3 includes an outer slide rail 31, a middle slide rail 32 and an inner slide rail 33, the middle slide rail 32 slides in the outer slide rail 31, and the inner slide rail 33 Slidingly connected in the middle slide rail 32, so that the smaller slide rail can slide and shift relative to the larger slide rail, and the detailed structure mode and action principle of each slide rail of the slide rail mechanism 3 belong to the prior art and It is not a technical feature of the wooden case, so it will not be described in detail here. The outer slide rail 31 is provided with a first through hole 311, and one end of the inner slide rail 33 is provided with a toggle portion 34, and the toggle portion 34 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com