Method for controlling solidification and cooling of heavy castings

A technology for large-scale castings and controlled cooling, applied in the field of casting, can solve problems such as difficulty in ensuring balanced cooling of castings, and achieve the effects of sequential solidification, accelerated solidification and cooling, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

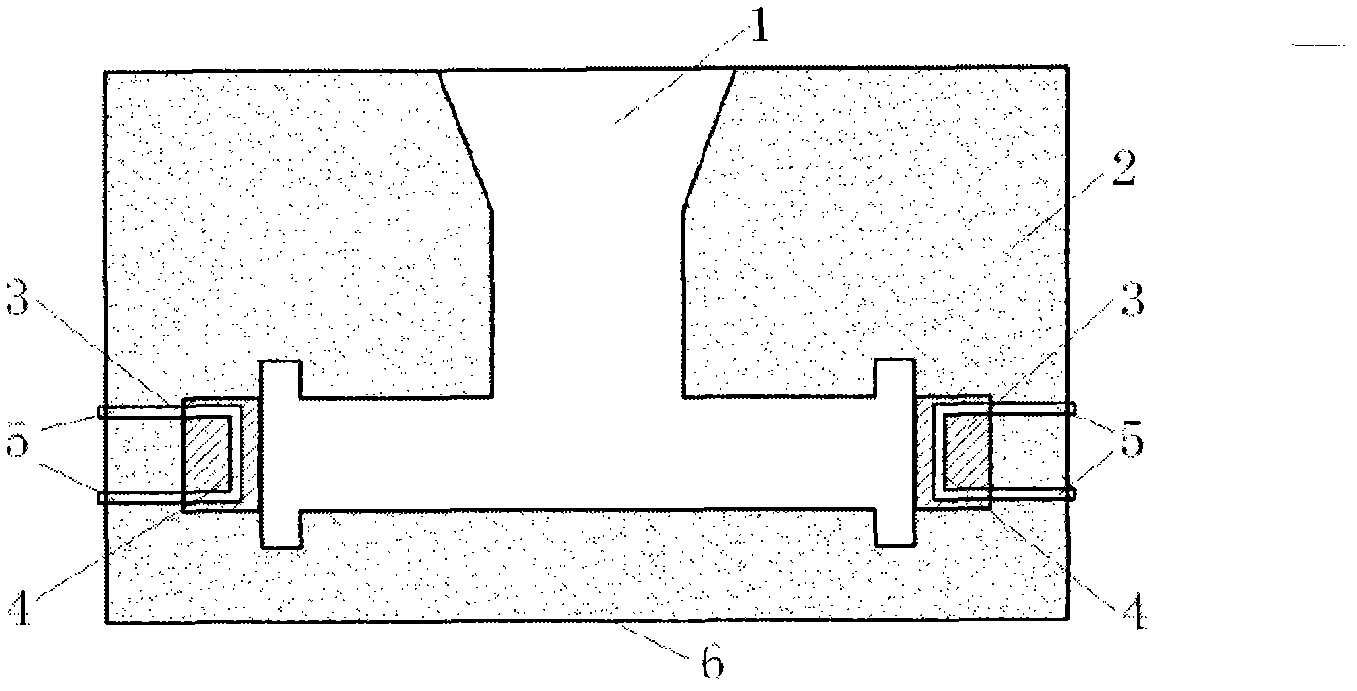

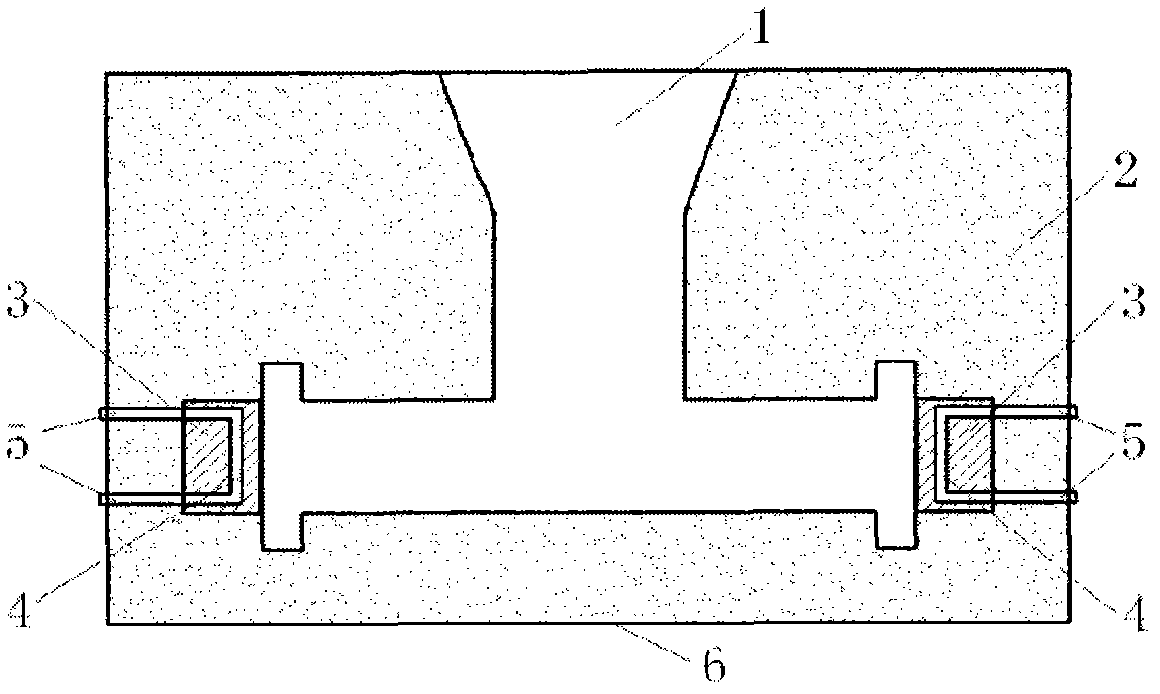

[0012] Combine the following figure 1 The preferred implementation process of the cold iron with cooling channels mentioned in the present invention is described. Specific steps are as follows:

[0013] In the first step, the cold iron 3 of the large casting 1 is designed, and the cooling channel 4 is arranged inside the cold iron 3 . The cooling channel 4 makes the hollow cold iron 3 have air isolation capability and hinders the heat transfer of the casting 1 from the cold iron 3 to the outside. The cooling channel 4 has airtightness and a certain strength to prevent cracks during use.

[0014] In the second step, place the cold iron 3 in the sand mold 2 of the thick part of the casting 1 during the molding of the large casting 1, and place the inlet and outlet pipes 5 of the cooling channel 4 in the cold iron 3 outside the sand box 6, so as to be compatible with the cooling Connection of media pipes.

[0015] In the third step, after the large casting 1 is poured, a cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com