Automatic millstone welder

A welding machine and grinding disc technology, applied in the mechanical field, can solve the problems affecting the welding quality, the performance of the grinding disc, the displacement of the cutter head, etc., and achieve the effect of good welding effect, high quality of the grinding disc, and uniform welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

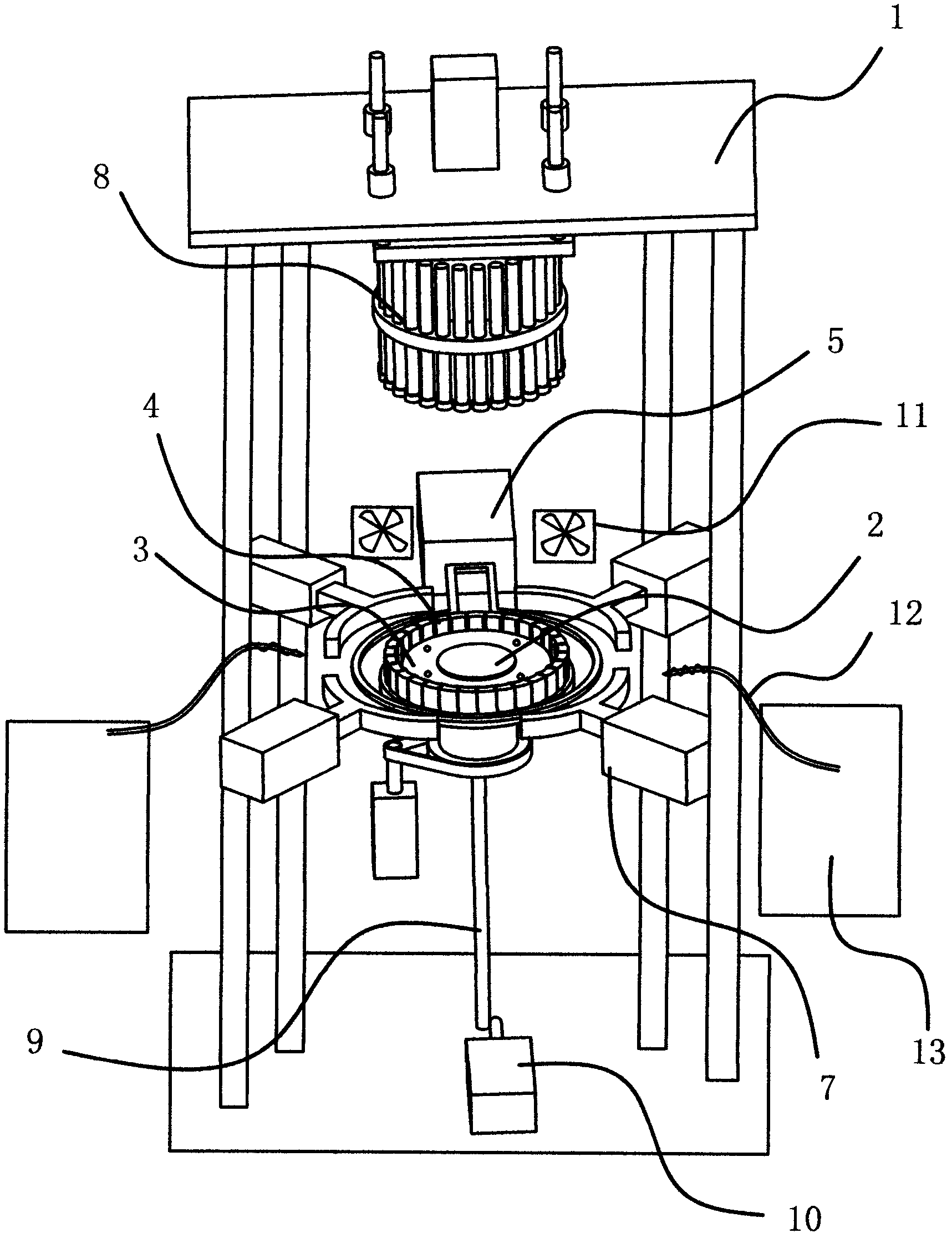

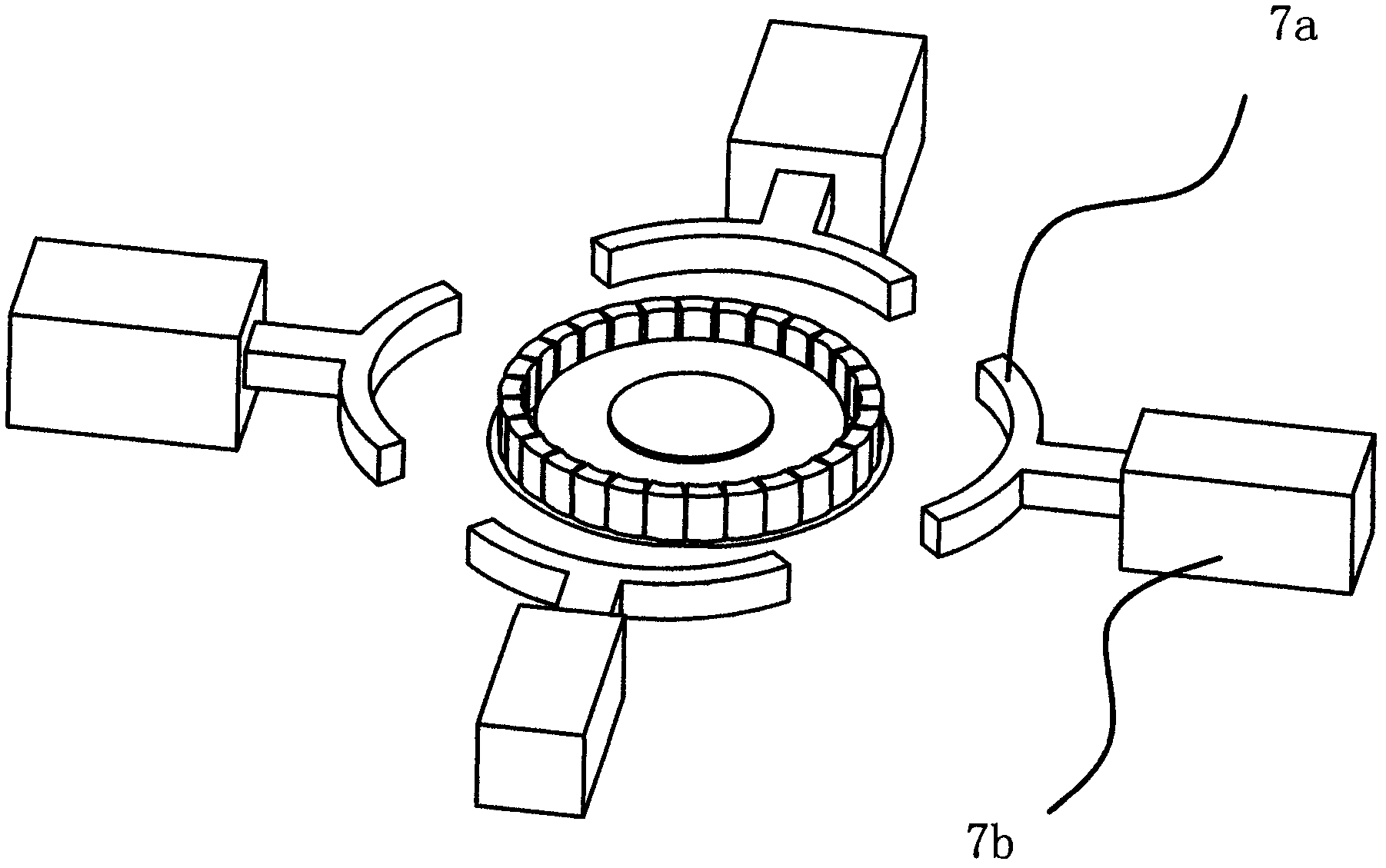

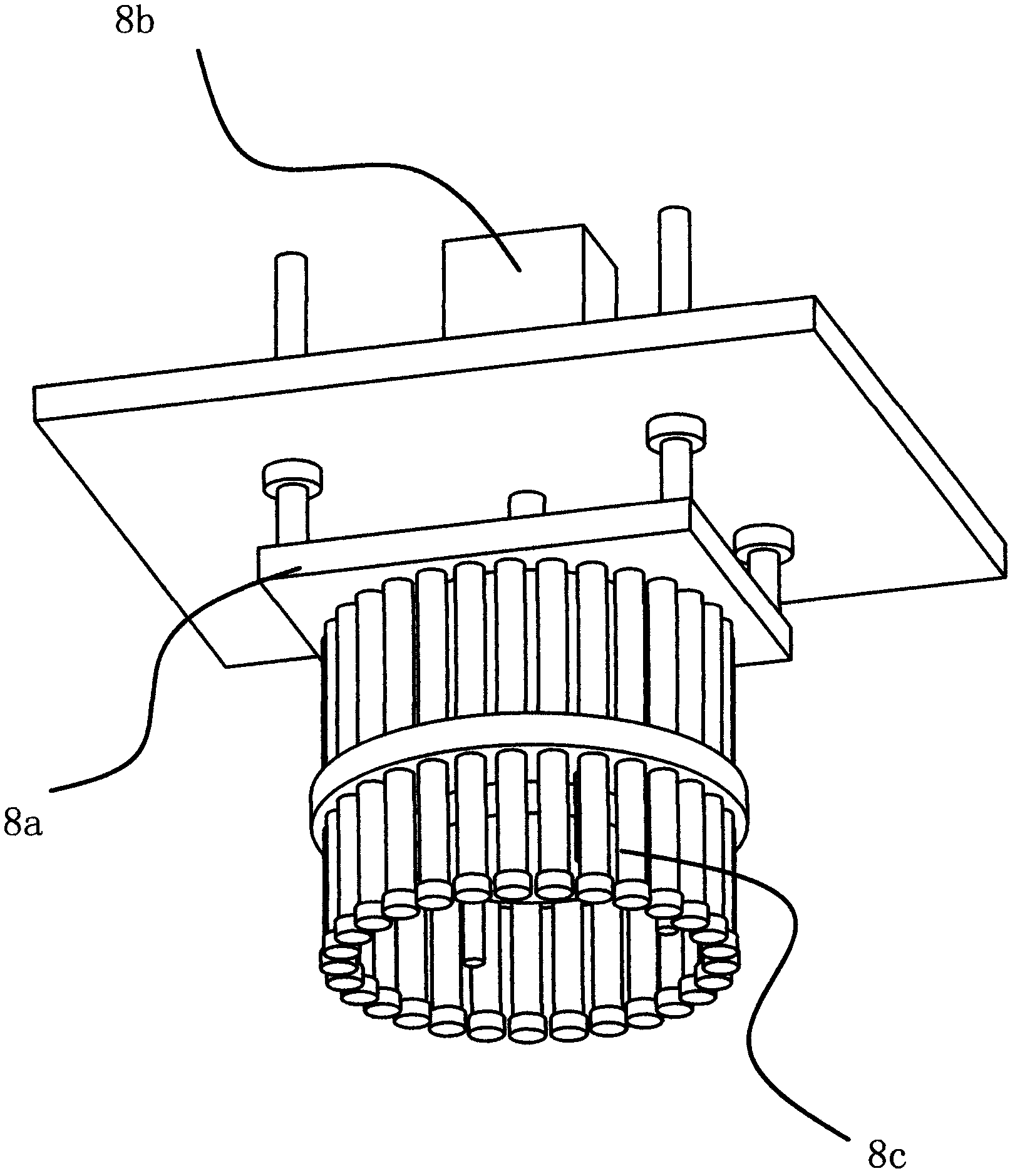

[0026] The edge of the grinding disc 3 has steps for positioning the cutter heads 4, and several cutter heads 4 are evenly distributed on the steps in the circumferential direction. like figure 1 As shown, the automatic grinding disc welding machine has a frame 1 and a working platform 2, the grinding disc 3 can be fixed on the working platform 2, and the outer ring of the working platform 2 is provided with a high-frequency induction for high-temperature heating and welding of the grinding disc 3 and the cutter head 4. Coil device 6. The working platform 2 is driven to rotate by the motor 5, and a correction device 7 is provided on the periphery of the working platform 2 to enable the cutter head 4 to be accurately positioned on the grinding disc 3, and a correcting device 7 that can squeeze the cutter head 4 and place it directly above the working platform 2 is provided. It is fixed on the pressing device 8 on the step of the grinding disc 3 .

[0027] Specifically, as fi...

Embodiment 2

[0029] The structure of embodiment two is basically similar to embodiment one, as Figure 5 As shown, the difference is that in embodiment one, the working platform 2 is a liftable structure, and in embodiment two, the high-frequency induction coil device 6 is a liftable structure, and a screw 9a is connected to the bottom of the high-frequency induction coil device 6, and the rotation of the screw rod 9a can drive The high-frequency induction coil device 6 moves up and down, and the screw rod 9a is driven by a stepping motor 10a. The purpose is all the same, all for the high-frequency induction coil device 6 and the correction device 7 not to interfere with each other in the work of the whole automatic grinding disc welding machine.

[0030] Although this article uses a lot of 1. frame; 2. working platform; 3. grinding disc; 4. cutter head; 5. motor; 6. high-frequency induction coil device; 7. correction device; One; 8, top pressure device; 8a, bracket; 8b, cylinder two; 8c,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com