Trailing arm suspending frame with double-transverse stay bar structure

A trailing arm and transverse strut technology, which is applied in the field of trailing arm suspension, can solve the problems of affecting vehicle handling performance, leaving a lot of space, and uneven force, reducing the risk of cracking, large layout space, and easy production and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

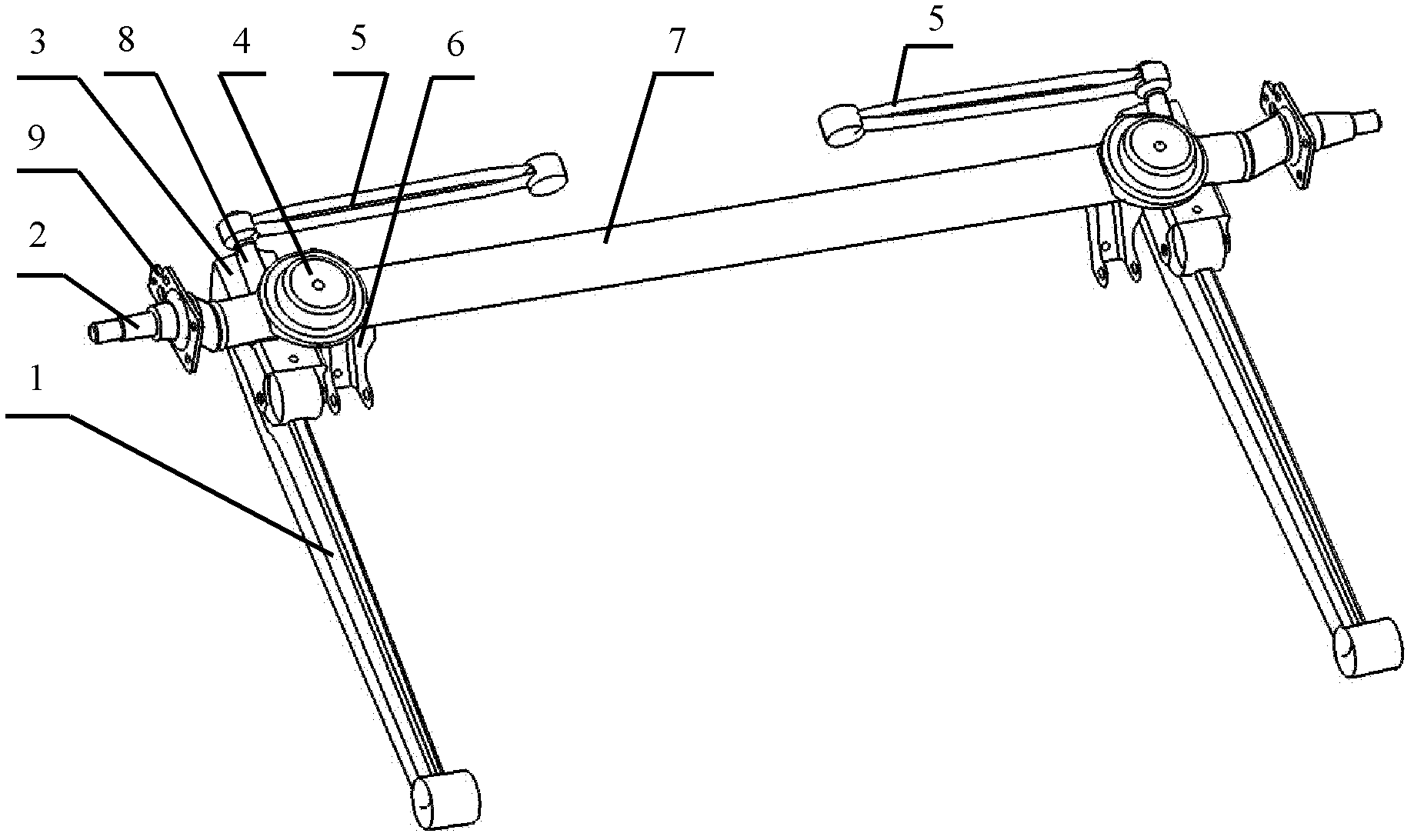

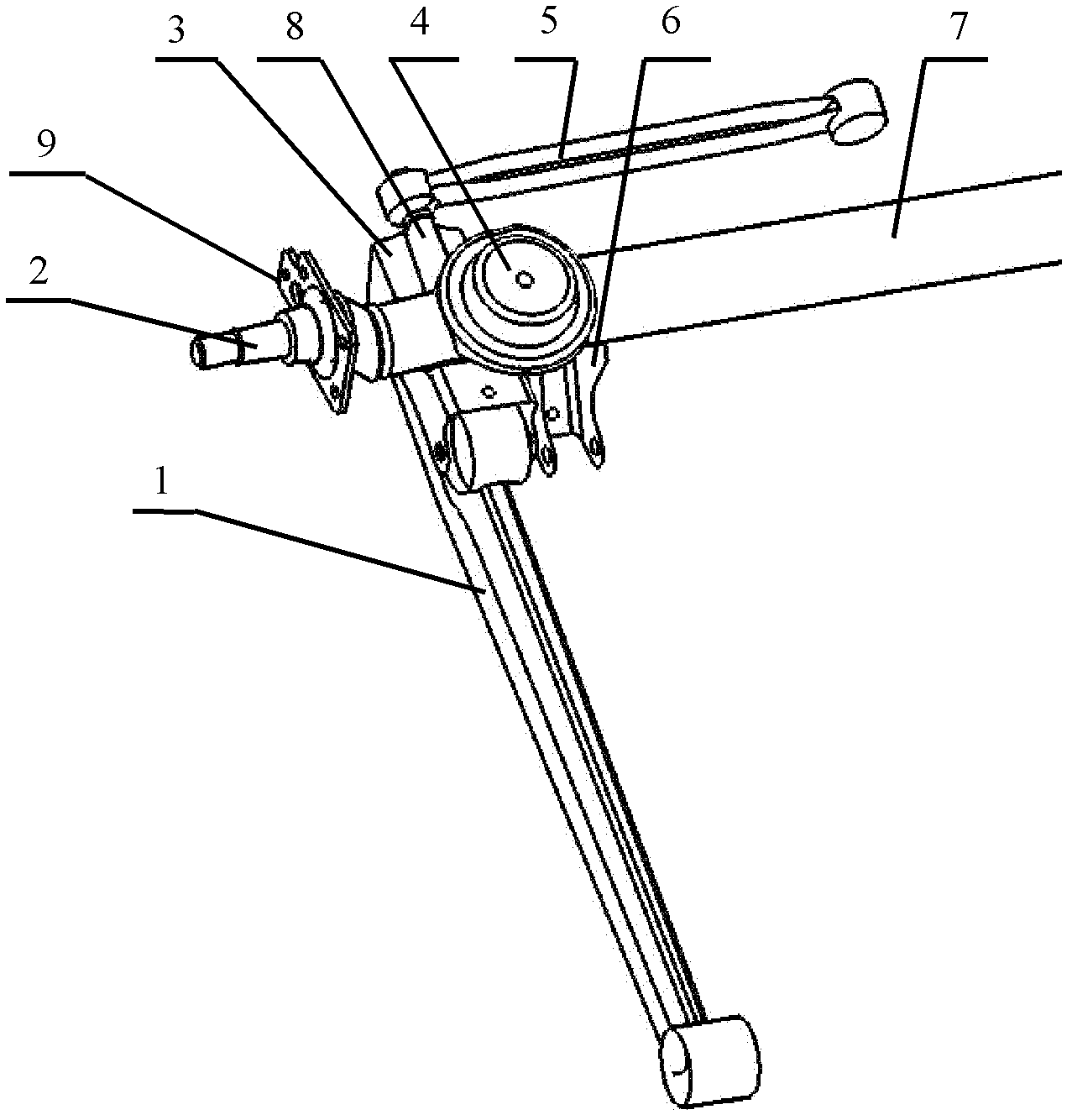

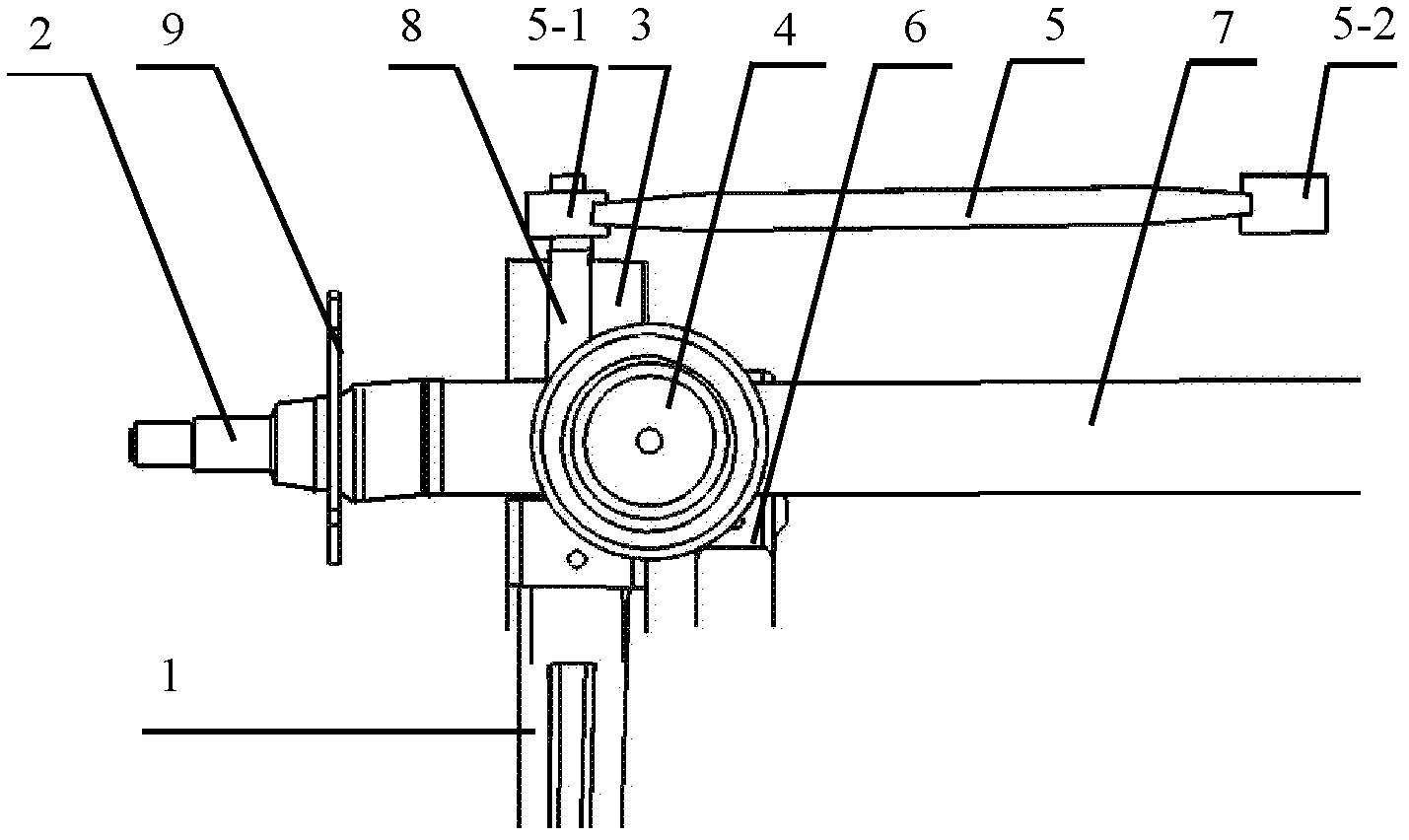

[0024] see figure 1 , figure 2 , image 3 , the embodiment of the present invention provides a trailing arm suspension with a double cross strut structure, which mainly includes a trailing arm 1, a hub shaft 2, a mounting bracket 3, a spring seat 4, a cross strut 5, and a shock absorber mounting bracket 6 , crossbeam 7, fixed rod 8, flange 9 and other parts; the two ends of the crossbeam 7 are provided with left and right symmetrical trailing arms 1, hub shaft 2, mounting bracket 3, spring seat 4, shock absorber mounting bracket 6 , fixed rod 8, flange plate 9, the improvement of the present invention is respectively hinged a cross strut 5 at the outer ends of two symmetrical fixed rods 8, and two cross struts 5 are identical in str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com