Bus frame structure

A technology of frame structure and passenger car, which is applied to the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of reducing the structural strength of the passenger car frame, and achieve the effect of solving the lack of layout space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

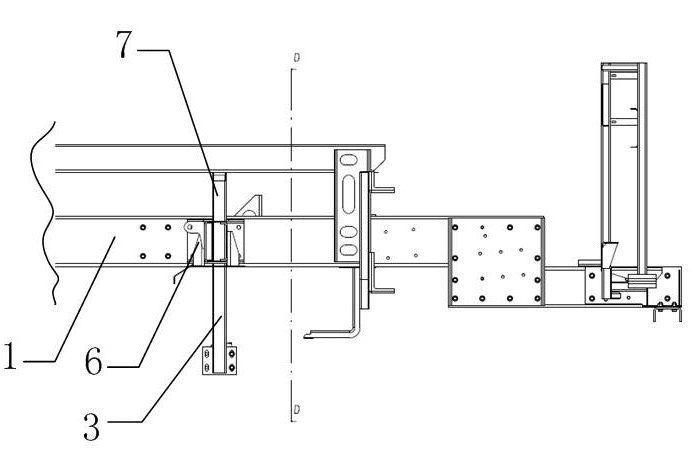

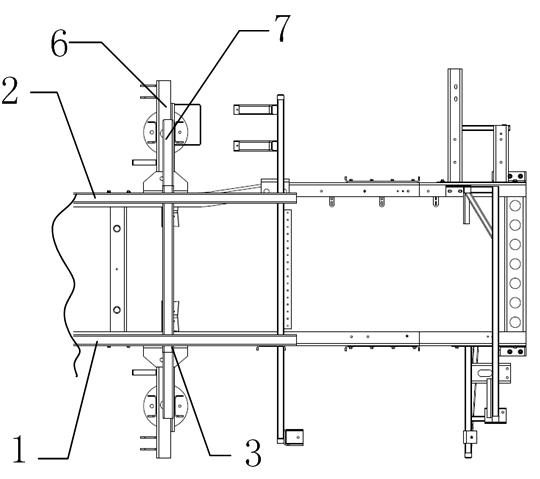

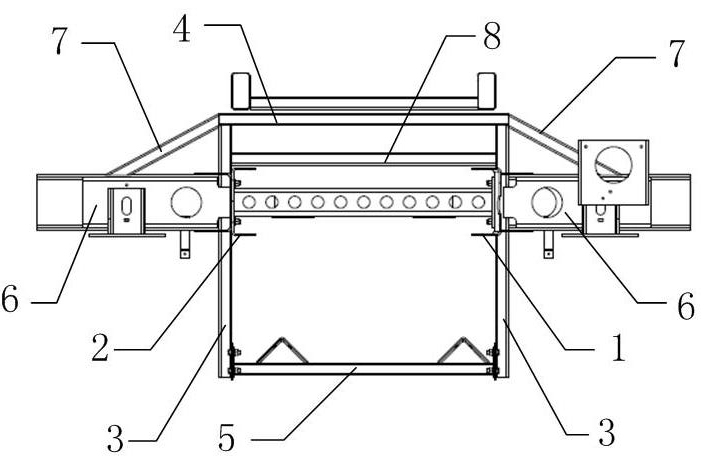

[0019] A kind of passenger car frame structure of the present embodiment, as Figure 1 ~ Figure 3 As shown, including the frame girder, the frame girder includes a left longitudinal beam 1 and a right longitudinal beam 2 arranged in parallel, and the relative positions of the outer sides of the left longitudinal beam 1 and the right longitudinal beam 2 are respectively fixed with a column 3, and the shaft of the column 3 The center line is perpendicular to the axes of the left longitudinal beam 1 and the right longitudinal beam 2; the upper ends and lower ends of the columns 3 are respectively connected by the upper beam 4 and the lower beam 5 to form a closed frame structure. The relative positions of the outer surfaces of the left longitudinal beam 1 and the right longitudinal beam 2 are also respectively fixed with outer beams 6, the axes of the outer beams 6 and the axis lines of the upper beam 4 and the lower beam 5 are parallel to each other and in the same plane. The ou...

Embodiment 2

[0022] A kind of passenger car frame structure of the present embodiment, the structure is similar to embodiment 1, the difference is: as Figure 4 As shown, extension beams 41 extend horizontally at the left and right ends of the upper beam 4 respectively, and the extension beams 41 on the same side and the outer beam 6 are connected in a Z-shaped structure by reinforcing diagonal braces 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com