Multi-joint chain link-type robot based on modularization

A modular, robotic technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of restricting the posture display of wheeled robots, unable to display swing, undulating actions, etc., and achieve the effect of increasing torque and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

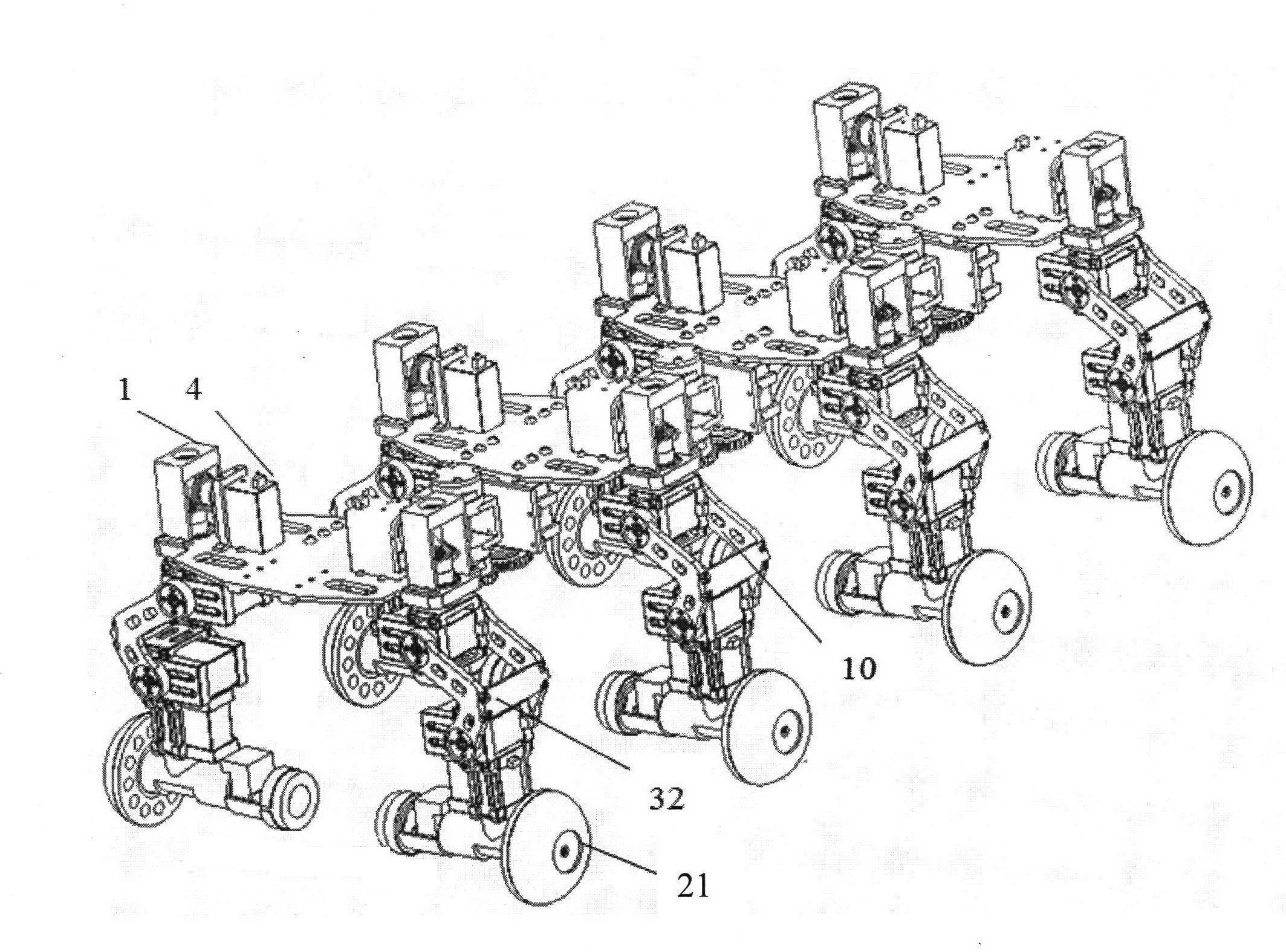

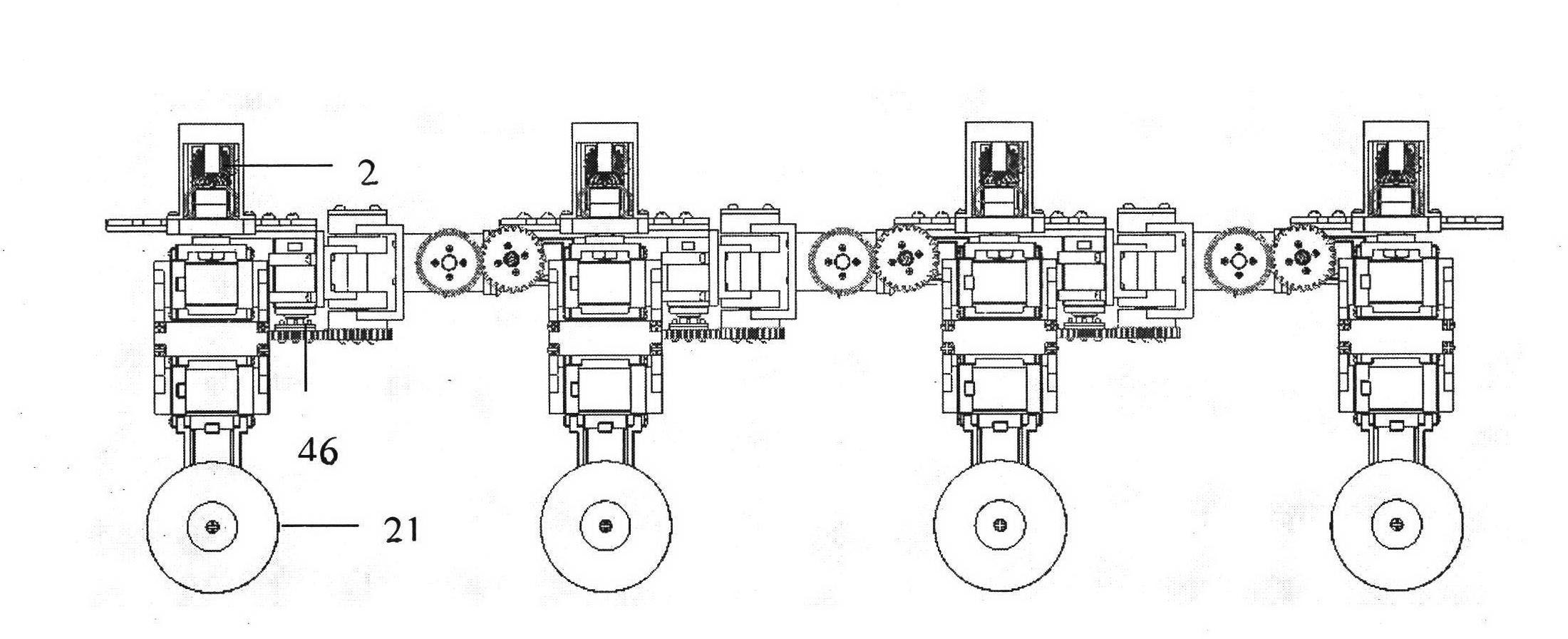

[0021] Such as figure 1 As shown, it is an overall schematic diagram of a chain-link robot based on multi-joint modularization, which is an eight-legged robot connected by four sets of waist and leg modules. There are 46 degrees of freedom in total, and each pair of feet is connected by three sets of waist connection modules.

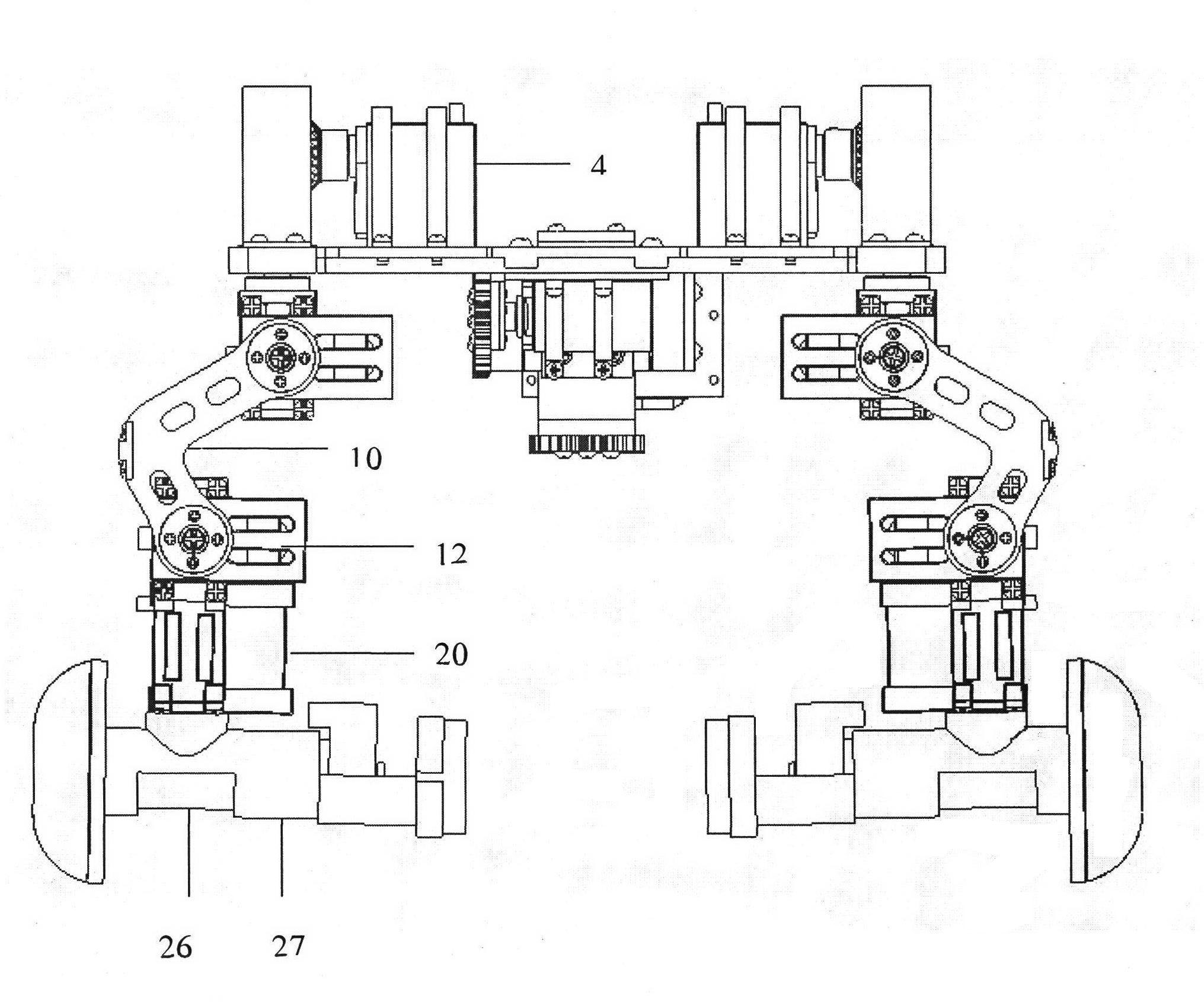

[0022] Such as image 3 As shown, the No. 1 steering gear is connected to the lower part through the No. 1 shaft, which prevents the motor shaft from directly bearing radial loads and improves the service life of the motor.

[0023] Such as Figure 5 As shown, when installing the sports foot, the steering gear support frame 1 (12), the steering gear support frame 2 (33), and the steering gear support frame 3 (16) are fixedly connected by screws, put the No. Machine supporting frame four (35) are fixedly connected by screw. After putting into the No. 3 steering gear (17), pass through another set of steering gear support frame one (15), steering gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com