Horizontal automatic-chain-arrangement hydraulic drum winch

A hydraulic drum and winch technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of high labor intensity, cumbersome work, low working efficiency of electric vertical winch, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The horizontal self-draining chain hydraulic drum winch of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

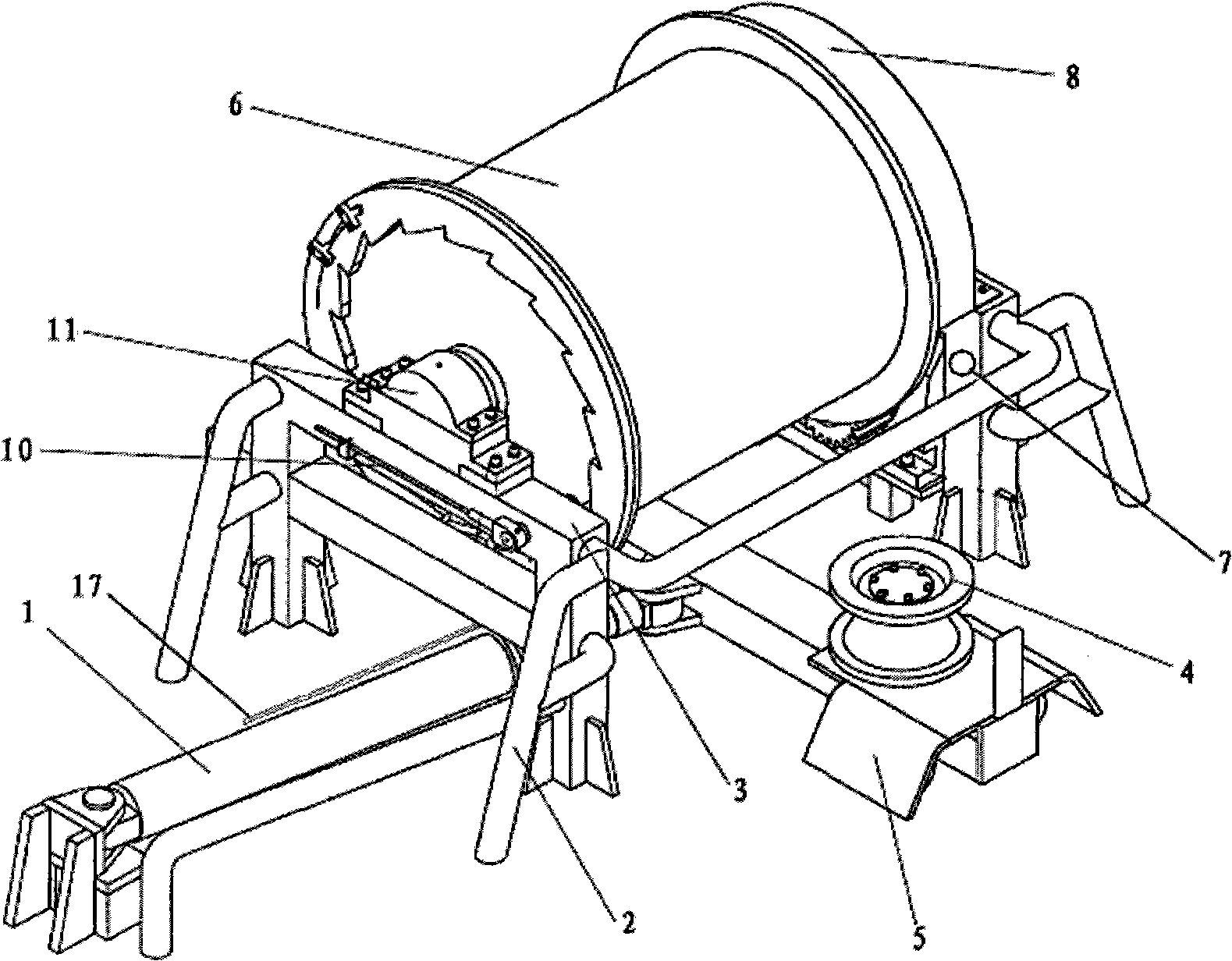

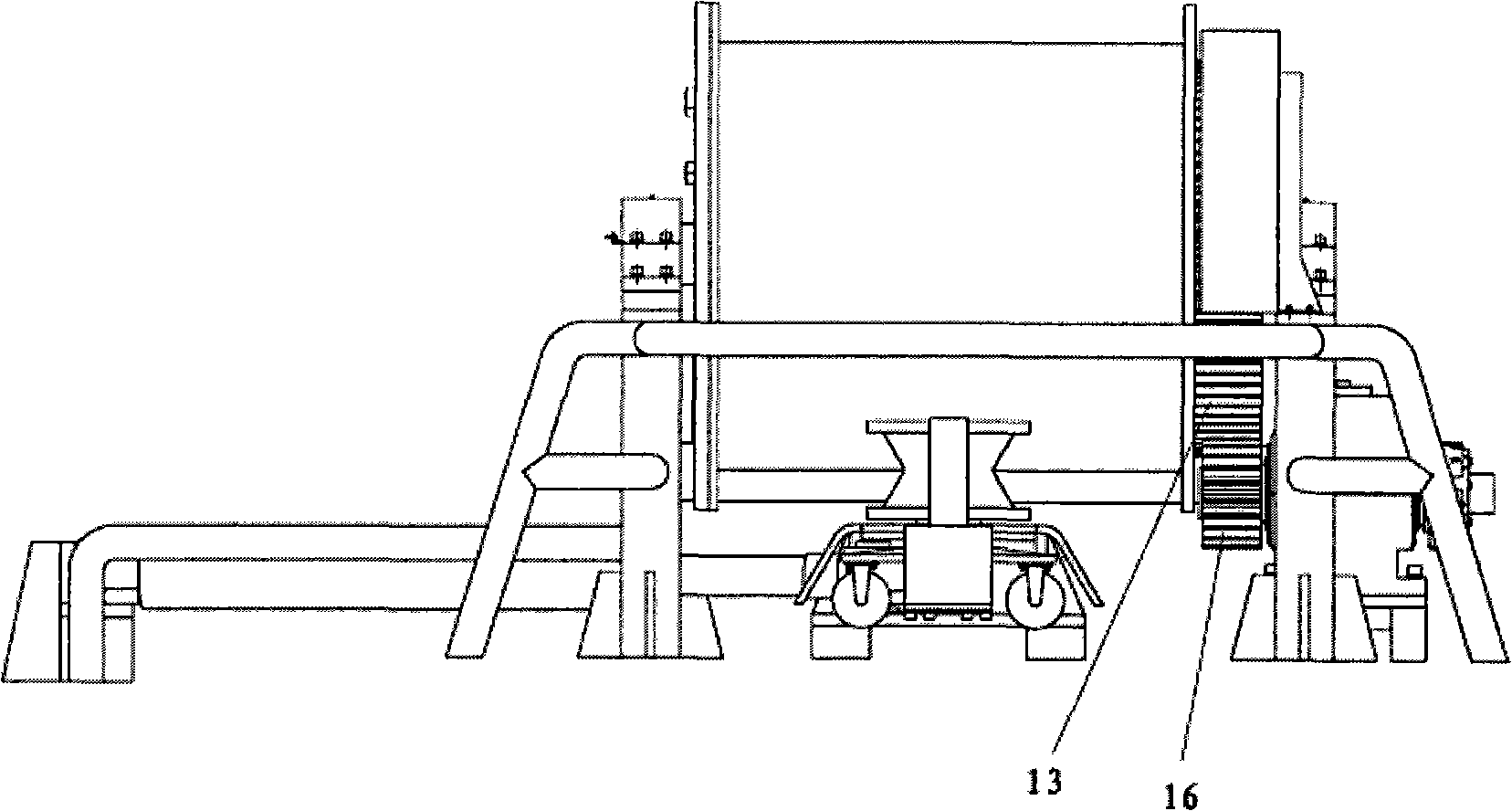

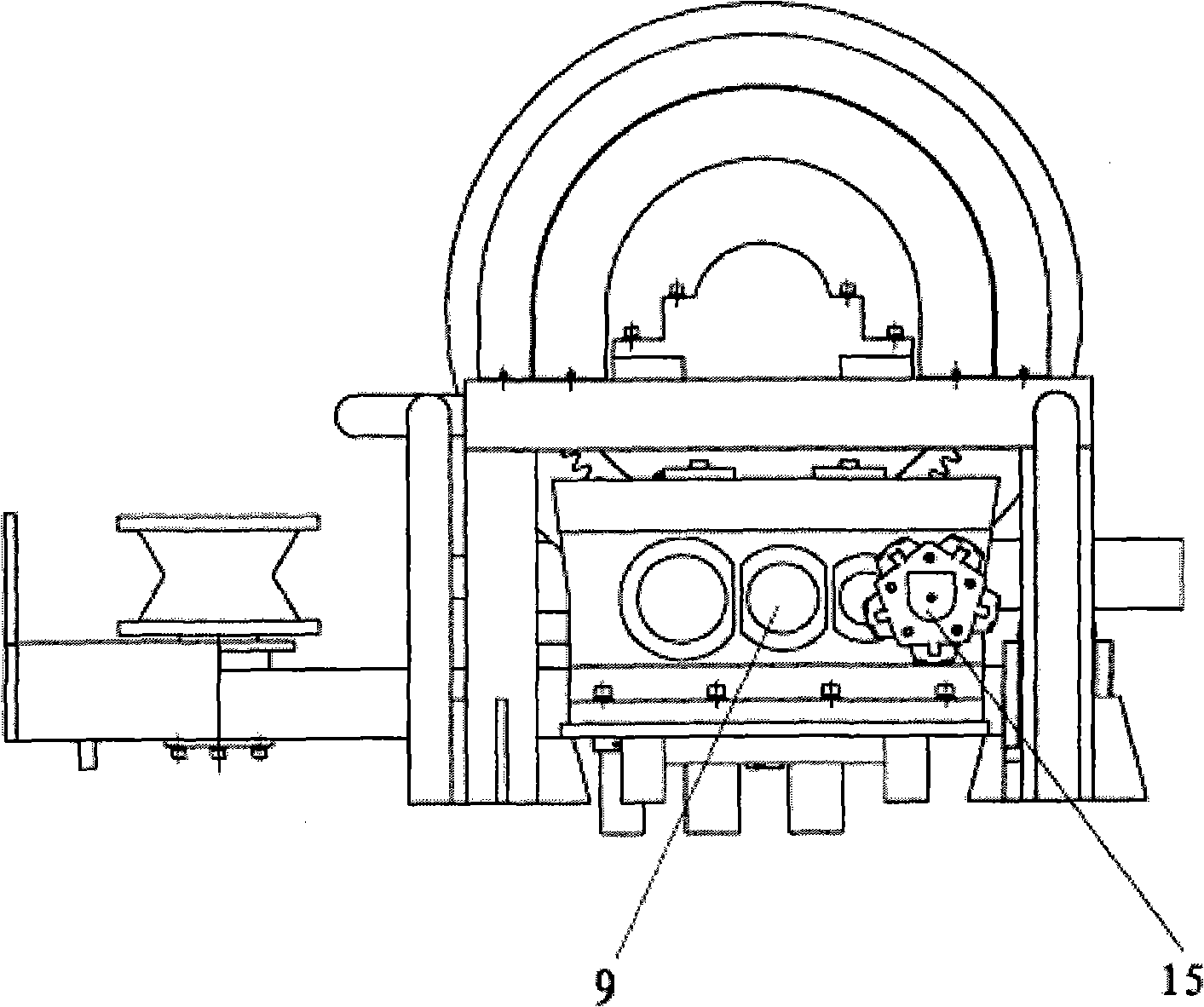

[0020] A horizontal self-draining chain hydraulic drum winch, composed of drum parts, turntable parts, bracket parts, reducer parts, hydraulic parts, electrical parts and control parts; the drum part is the main part to realize the function of the device ;Such as figure 1 , figure 2 , Figure 4 As shown, the reel part is composed of a reel 6, a ratchet 14, a large gear 13, a gear cover 8, and a rotating shaft 11; wherein, the rotational power of the entire part comes from the rotation of the large gear 13;

[0021] Such as figure 1 As shown, the turntable part is a functional part that guides the direction of the anchor chain and causes the anchor chain to generate horizontal displacement during the coiling process, so that it is evenly distributed on the reel. , chain cylinder 1; one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com