Mounting bracket for overhead working

A technology for installing brackets and high-altitude operations, applied in lifting frames, lifting devices, etc., can solve problems such as difficulties, large volumes, and dangerous air ducts, and achieve the effects of low production costs, multiple application fields, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

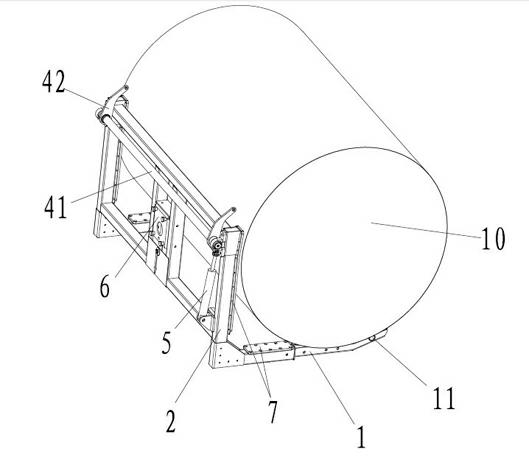

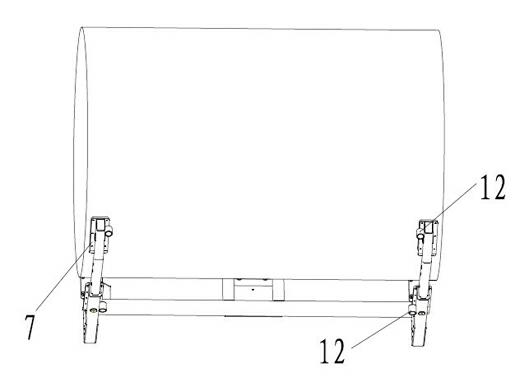

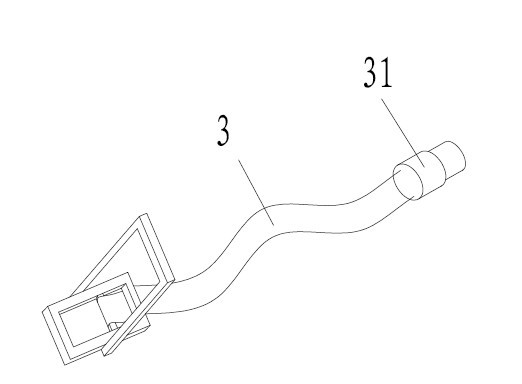

[0036] As shown in the accompanying drawings, a mounting bracket for aerial work includes a frame body. The frame body includes a horizontal support bracket 1 and a side support bracket 2 arranged perpendicularly to each other. The frame body is provided with a steering support device. It is used to connect the connecting seat 6 of the steering support device and the locking device for fixing the object to be installed; the locking device includes a tight rope 3 connected between the horizontal support bracket 1 and the side support bracket 2, and is arranged on One end of the tight rope 3 is connected to the tensioning assembly for tensioning the tight rope 3 on the support 2 . The tensioning assembly includes a rotating shaft 41 arranged on the upper part of the side support bracket 2, a crank arm 42 located at both ends of the rotation shaft 41 and rotating around the rotation shaft 41 as an axis, and a piston rod and a crank arm 42 arranged at the lower part of the side sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com