Plugging agent for clastic rock oil reservoir horizontal well, preparation method and water plugging method

A technology for horizontal wells and clastic rocks, which is applied to the plugging agent of horizontal wells in heterogeneous clastic rock reservoirs and the field of oil well water plugging using the plugging agent, which can solve the problem of difficult plugging agents, non-recyclable, oil and water output at the same time, etc. problems, to achieve the effect of reducing the cost of plugging agent and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

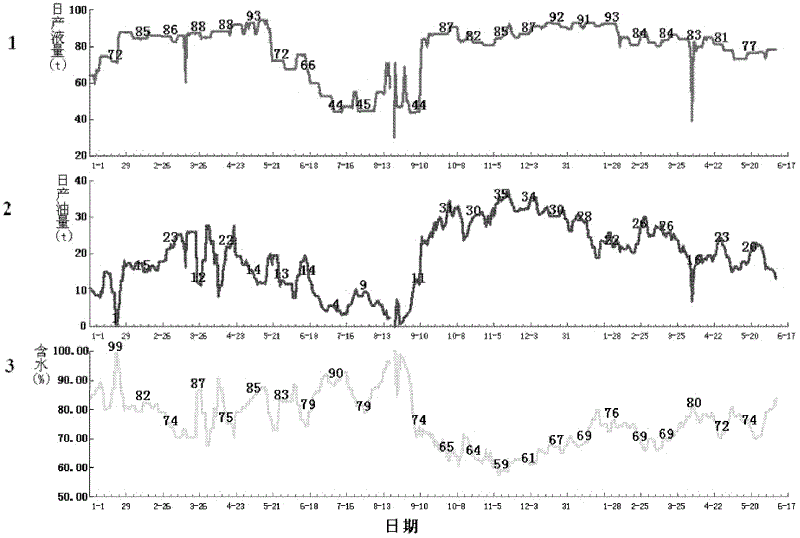

Image

Examples

preparation example Construction

[0047] A preparation method of the above blocking agent, the method comprising: in parts by weight, adding 0.5-1.5 parts of nonionic emulsifier and 2-4 parts of anionic surfactant to 100 parts of crude oil successively, adding 0-40 parts of water, preferably 20-40 parts, fully stirred until uniform, made into emulsion blocking agent.

[0048] A method for shutting off water in a horizontal well in a clastic rock reservoir, the method comprising: using the above-mentioned plugging agent, according to 6-30m 3 / h displacement, inject 0.4-2.0m per meter horizontal section 3 The amount of plugging agent, the plugging agent is stably injected into the horizontal well through the tubing or casing annulus, and the well is opened for production after 24-72 hours of boredom. In the present invention, a profile control pump or a cement truck can be used to inject the plugging agent into the horizontal well through the oil pipe or the annulus of the oil casing, and a 700 type skid-mounte...

Embodiment 1

[0080] Choose a viscosity of 70mPa.s at 50°C and a density of 0.938g / cm 3 of crude oil. Add 0.5 kg of imidazoline oleate and 2 kg of sodium dodecylbenzene sulfonate in sequence to 100 kg of crude oil, stir well until uniformly dispersed, and make an emulsion liquid blocking agent.

Embodiment 2-41

[0082] The preparation method used in Examples 2-41 is basically the same as that of Example 1. For the examples containing formation water, after the dispersion of crude oil and emulsifier is completed, formation water is added and stirred until uniformly dispersed. See Table 2 for details.

[0083] Table 2

[0084]

[0085]

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com