Lateral wall supporting device and supporting bracket with same

A technology of support device and side guard, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problem of damage to the integrity and stability of roadway rock formations, and the inability to support side walls and side walls. Solve problems such as low support strength, and achieve the effect of simple structure, stable function, safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

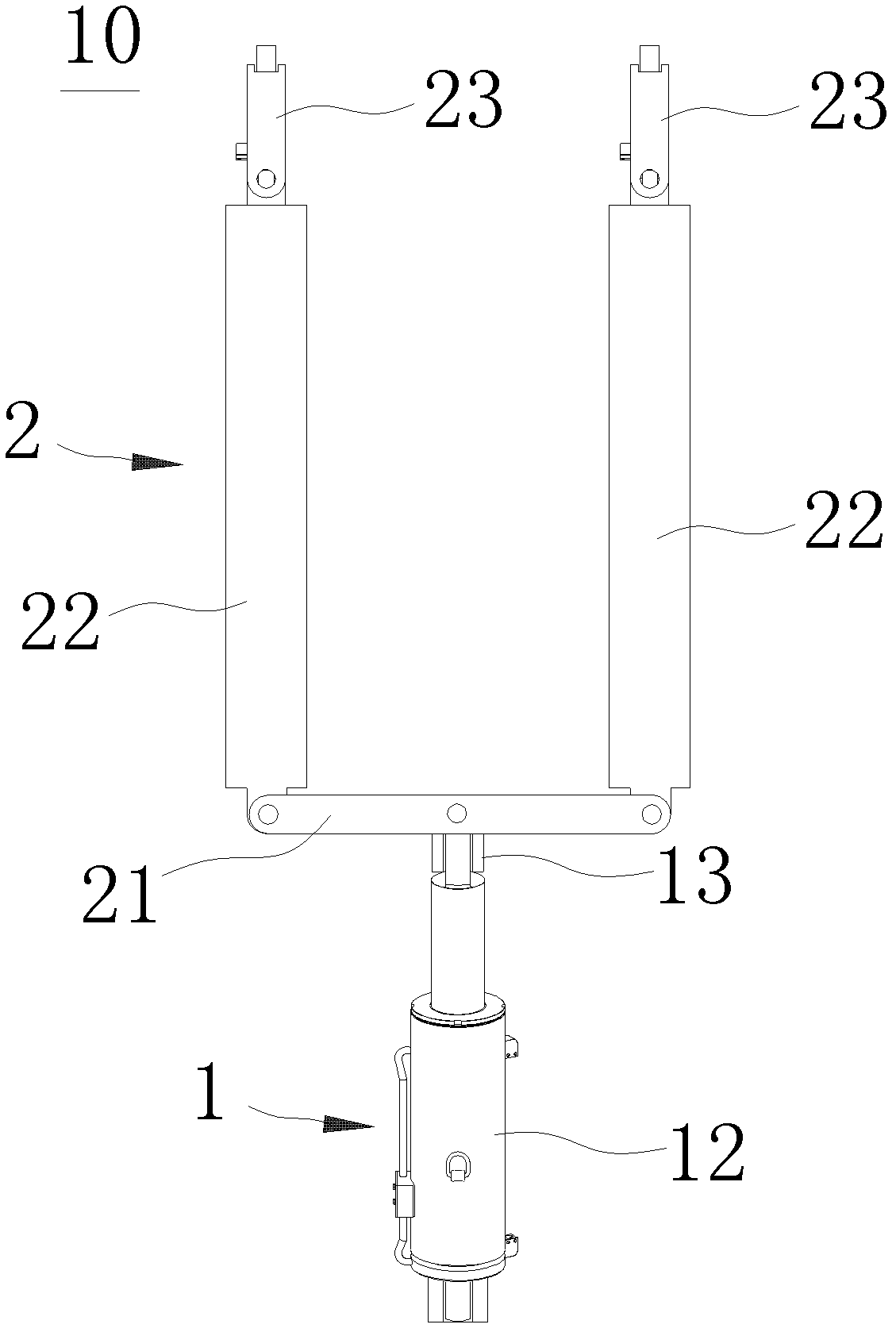

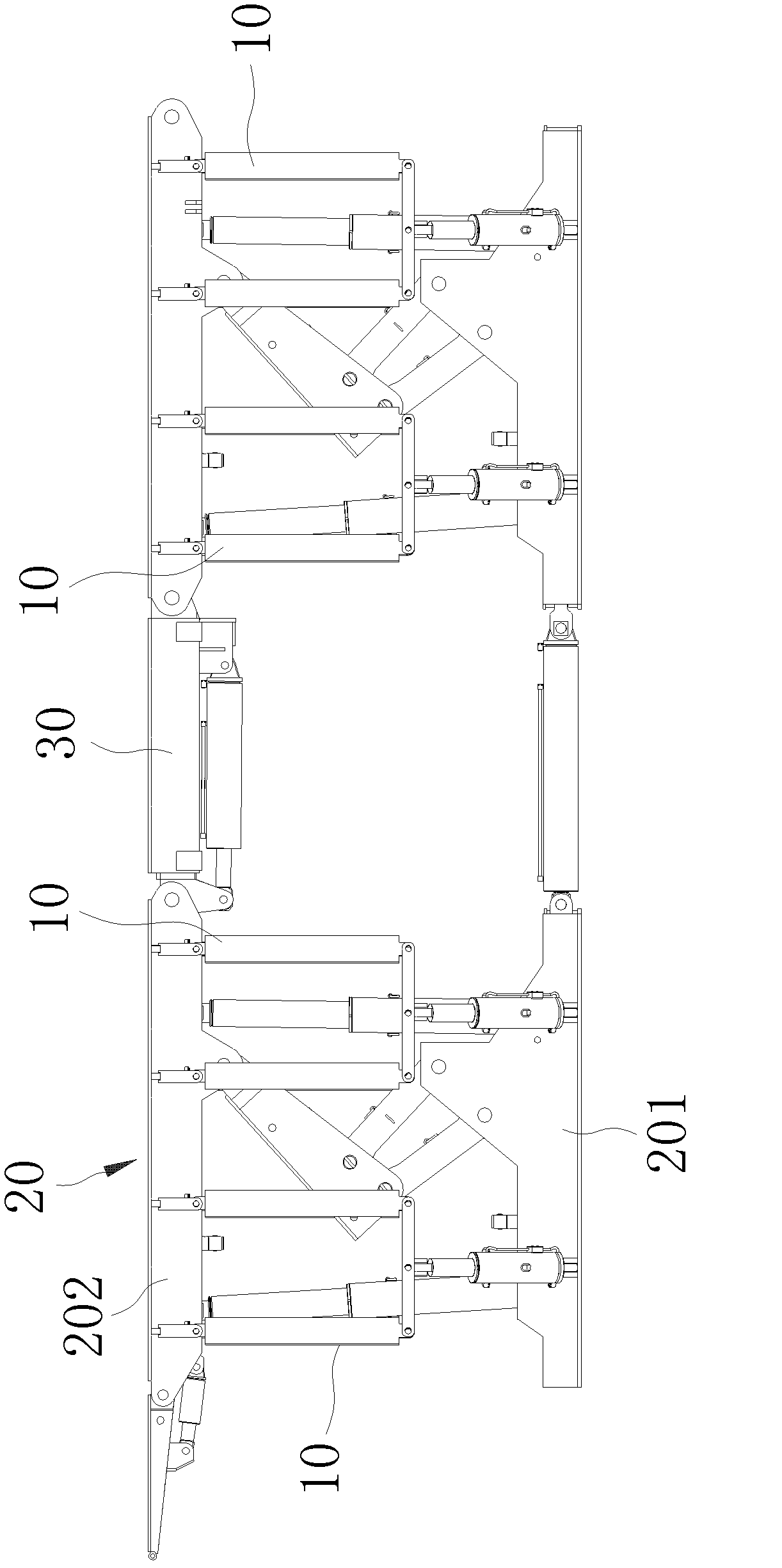

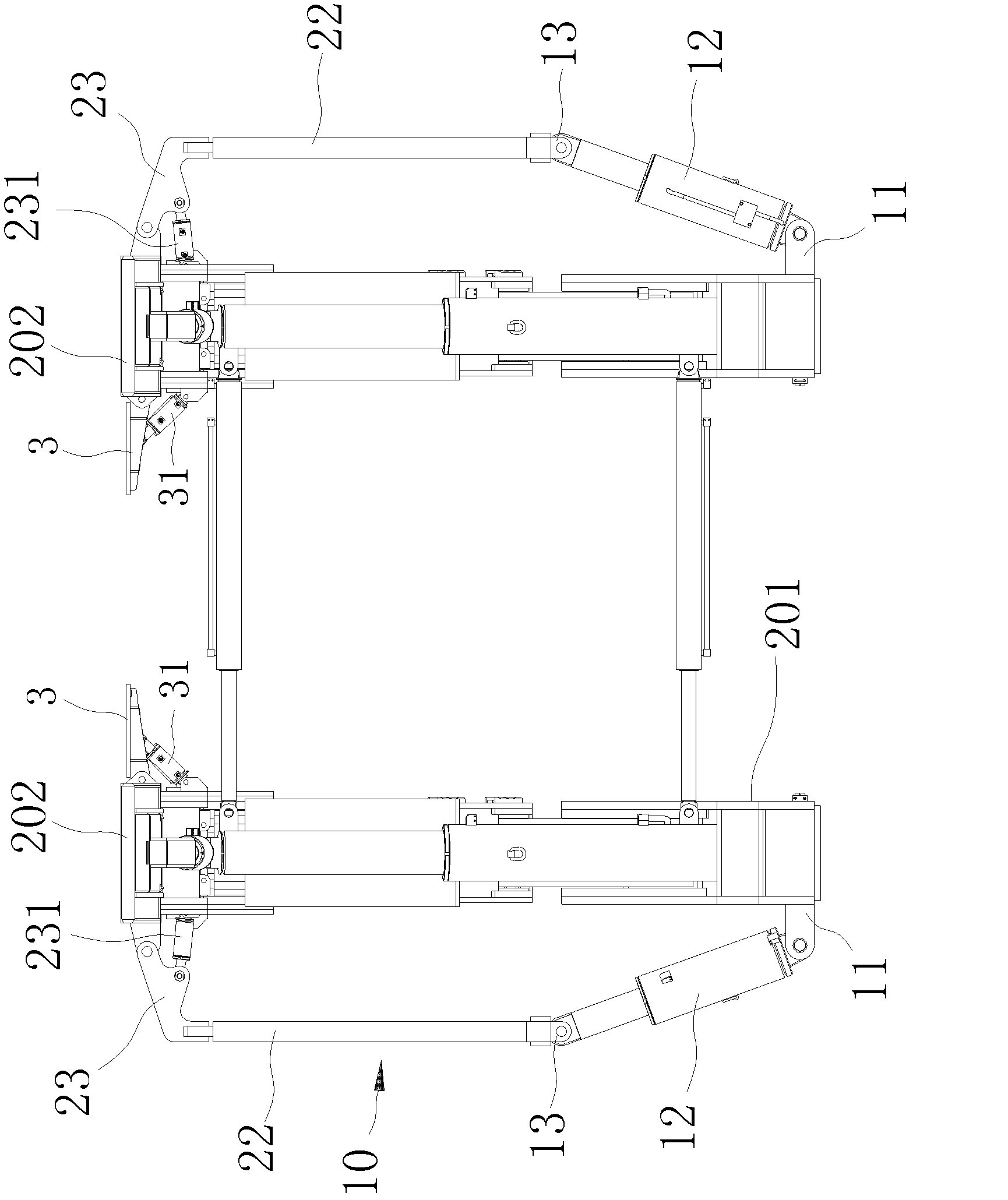

[0046] Please refer to figure 1 , figure 2 and image 3 ,in figure 1 It is a structural schematic diagram of the first embodiment of the side support device of the present invention, figure 2 It is a schematic diagram of the front view of the support bracket of the present invention, image 3 It is a schematic side view of the support bracket of the present invention. As shown in the figure, the side support device 10 of the present invention is arranged outside the main body 20 of the support bracket to provide the side support function. The side support device 10 mainly includes: The power support part 1 and the support side board part 2, wherein the power support part 1 is used to support the support side board part 2 and provide power for the movement of the support side board part 2, and its bottom end is movably connected to the main body 20 of the support bracket The top of the base 201 is movably connected to the bottom end of the support side board part 2; The ...

no. 2 example

[0052] Please refer to Figure 4 , is a schematic structural diagram of the second embodiment of the side support device of the present invention, as shown in the figure, the difference between the structure of the side support device of the second embodiment and the above-mentioned first embodiment is: the support in this embodiment The side guard part 2 only includes a vertical side guard 22, and the bottom end of the vertical side guard 22 is movably connected to the top of the power support part 1 (that is, the supporting oil cylinder 12) through the second two-way joint 13, and the vertical side guard The top of the plate 22 is movably connected to the top beam 202 through the third two-way joint 23, so that the dynamic support part 1 and the vertical side guard 22 have the freedom of movement in the corresponding direction (that is, the dynamic support part described in the first embodiment above). 1 can swing in the direction of the plane A relative to the supporting sk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com