Tapping back-off locking nut

A technology of anti-loosening nuts and undercuts, which is applied in the direction of nuts, screws, bolts, etc., can solve the problems of reduced work efficiency, complicated process, and increased process, and achieves the effect of convenient operation, simple process, and anti-rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

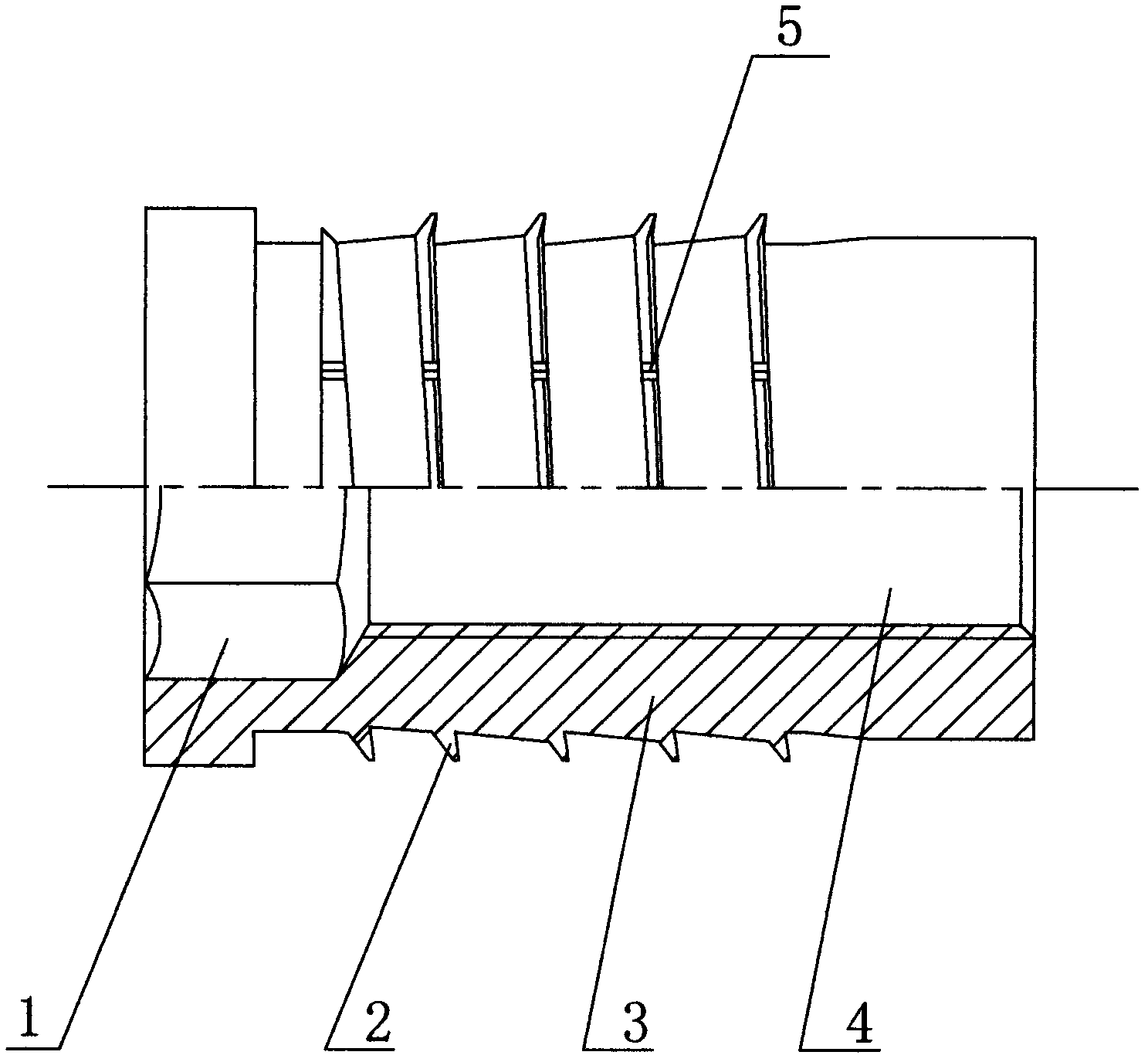

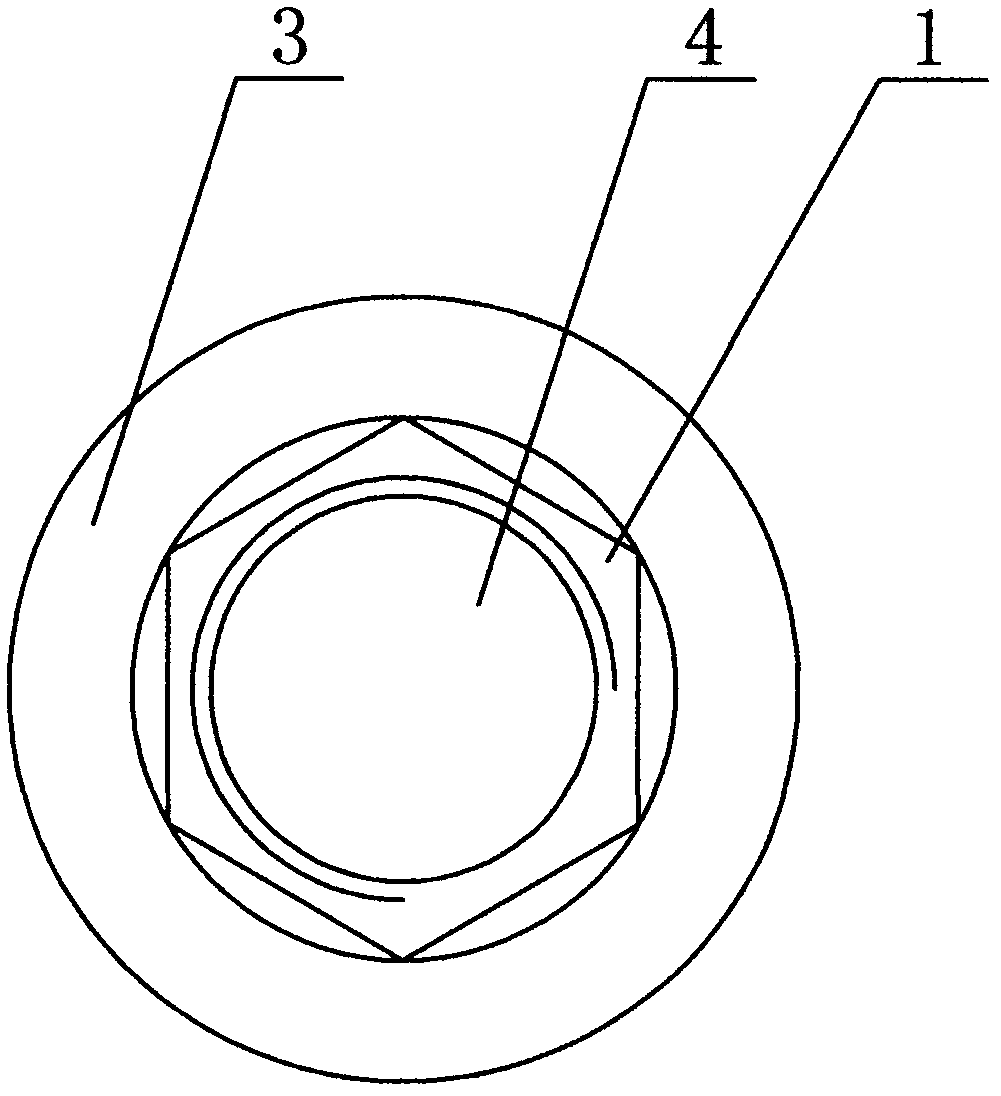

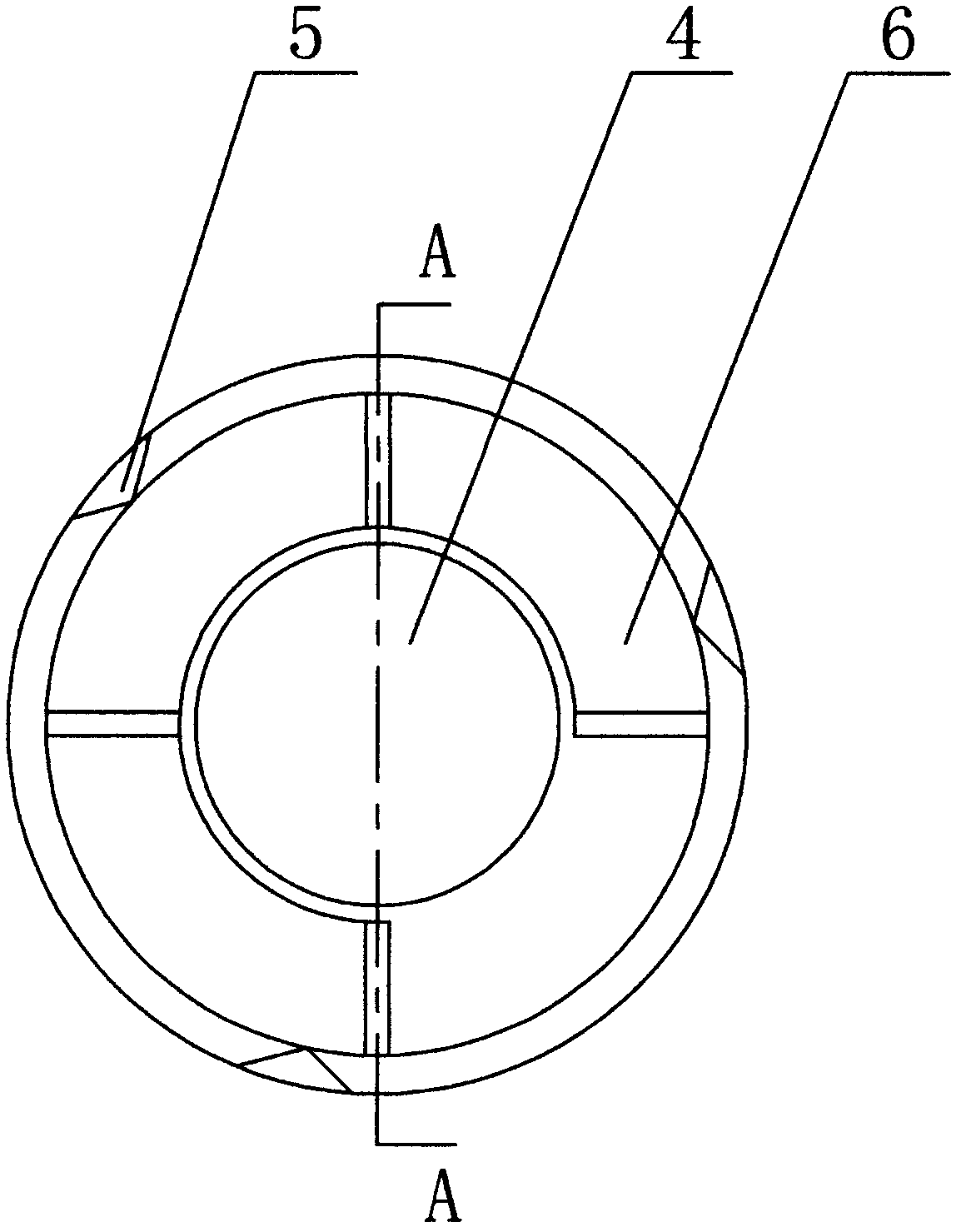

[0013] like Figure 1 to Figure 4 A self-tapping undercut anti-loosening nut is shown, comprising a nut column body 3, the interior of the nut column body 3 is provided with a threaded hole 4 and an inner hexagonal drive head 1 at one end of the threaded hole 4, and the nut column body 3 is provided with There are self-tapping undercuts 2 with a taper; the self-tapping undercuts 2 are provided with three inclined grooves 5; Raised 6.

[0014] This kind of nut is installed when it needs to be used. It is usually installed on a plastic plate. The inner hexagonal drive head 1 is driven by an electric tool, the nut rotates, and the self-tapping undercut tooth 2 is screwed into the mounting hole on the plastic plate by self-tapping. The debris produced by self-tapping is embedded in the chute 5 on the self-tapping undercut tooth 2, which can achieve the effect of anti-loosening and anti-rotation. Prevents rotation of the nut; the diameter of the mounting hole is slightly smaller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com