Heavy vehicle mass and mass center detection device

A technology for detection devices and heavy-duty vehicles, applied in measuring devices, weighing, testing of machines/structural components, etc., can solve problems such as poor measurement accuracy and uneven force on sensors, and achieve optimal layout, uniform force, and The effect of accurate mass size and centroid position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

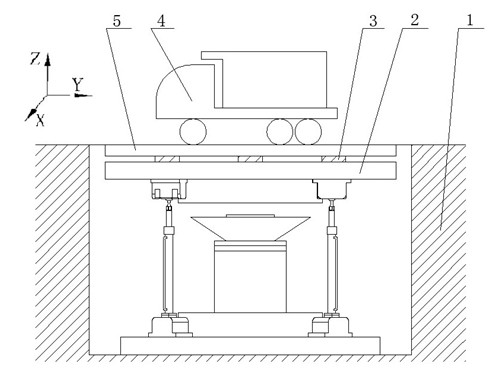

[0021] Such as figure 1 , figure 2 , image 3 As shown, the device of the present invention includes a foundation pit 1 , a four-degree-of-freedom platform 2 , a pressure sensor 3 , a vehicle under test 4 , and a horizontal platform surface 5 .

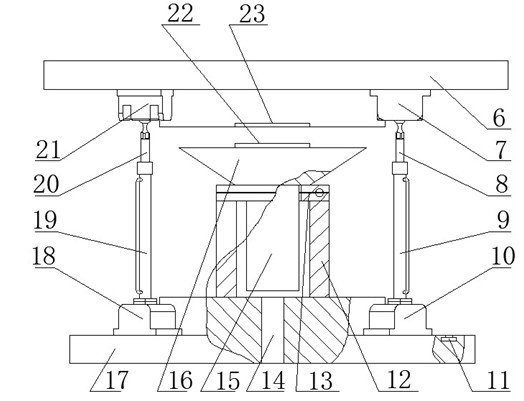

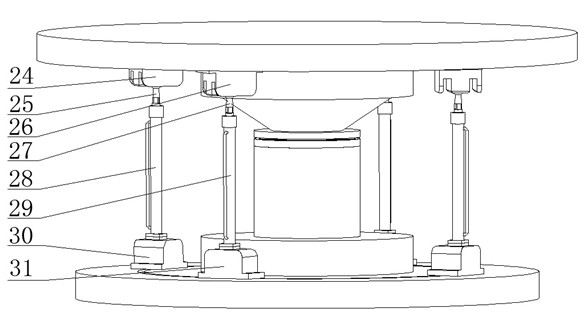

[0022] The four-degree-of-freedom platform 2 is installed in the foundation pit 1, such as Figure 4 As shown, on the upper surface of the upper cylindrical part of the upper platform 6 in the four-degree-of-freedom platform 2, ten pressure sensors 3 are arranged according to the Archimedes spiral from the center to the edge; the pressure sensor 3 is covered with a horizontal platform 5, which is The test vehicle 4 is placed on the horizontal platform 5.

[0023] Such as figure 2 , image 3 As shown, the four-degree-of-freedom platform 2 includes an upper platform 6, a second upper hinge support 7, a second piston 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com