Novel on-line monitoring sensor for iron content in oil and monitoring method of novel on-line monitoring sensor

A sensor and iron content technology, applied in the field of sensors, can solve the problems of expensive devices, difficult to popularize widely, complicated operation, etc., and achieve the effects of low cost, simple operation, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

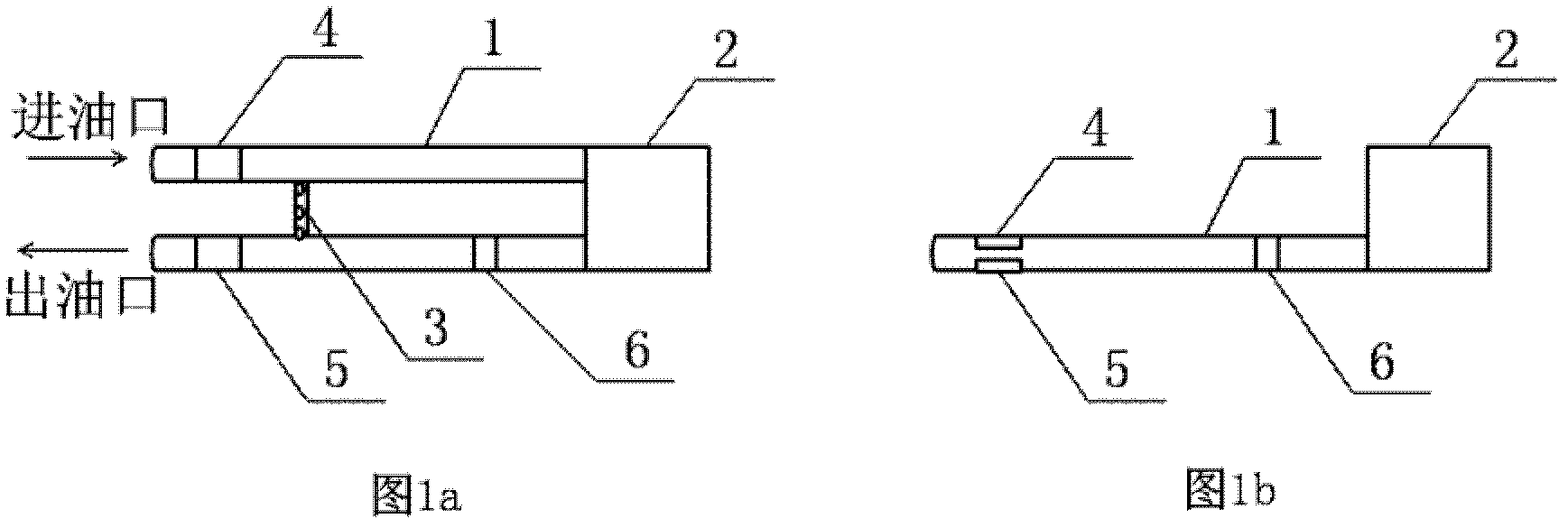

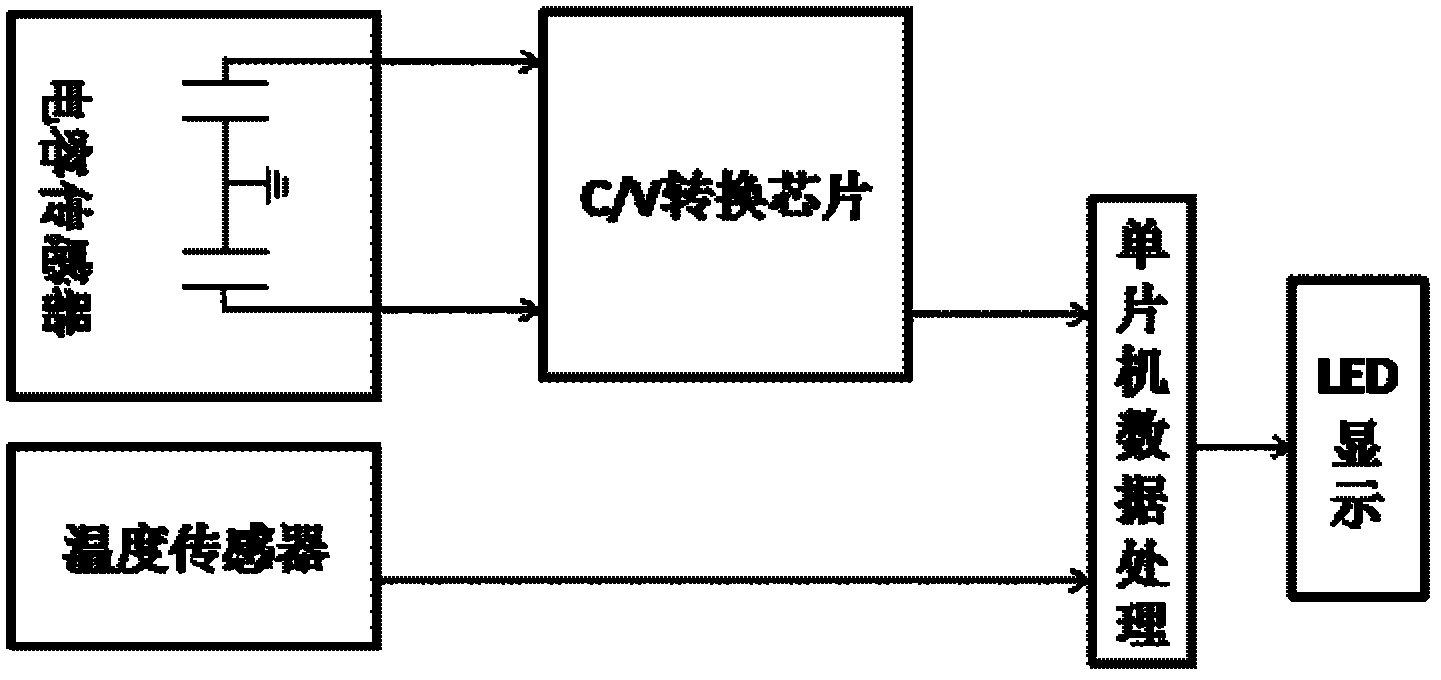

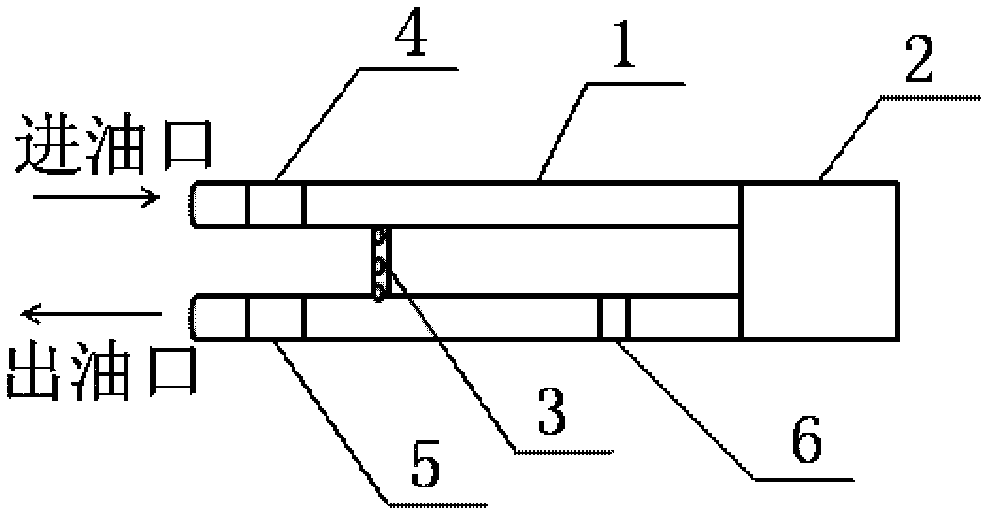

[0019] Such as figure 1 As shown, the present invention is a novel sensor for on-line monitoring of iron content in oil products, comprising a detection pipeline 1, and the inner wall of the pipeline at the two ports of the detection pipeline 1 is respectively provided with a first capacitance probe 4 and a second capacitance probe 5. A capacitance probe 4 and a second capacitance probe 5 are hollow, and their outer wall shape is adapted to the inner wall shape of the detection pipeline 1, and are arranged on the outer wall of the detection pipeline 1 between the first capacitance probe 4 and the second capacitance probe 5 There is an iron remover 2 and a terminal 3 connected with the first capacitance probe 4 and the second capacitance probe 5 . In this embodiment, the detection pipeline 1 is U-shaped, the iron remover 2 is arranged outside the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com