Conductive sensitive film three-layer structure

A three-layer structure and sensitive film technology, applied in the direction of material electrochemical variables, etc., can solve the problems of response baseline drift, small sensor response value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

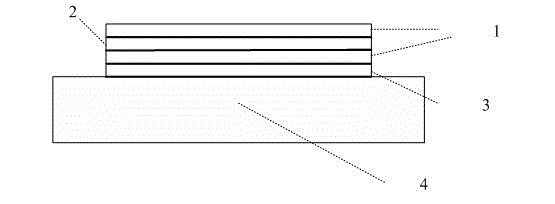

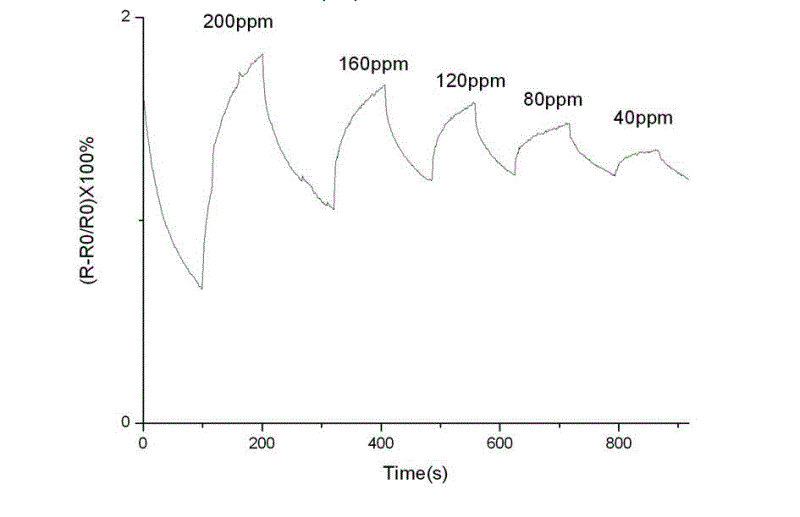

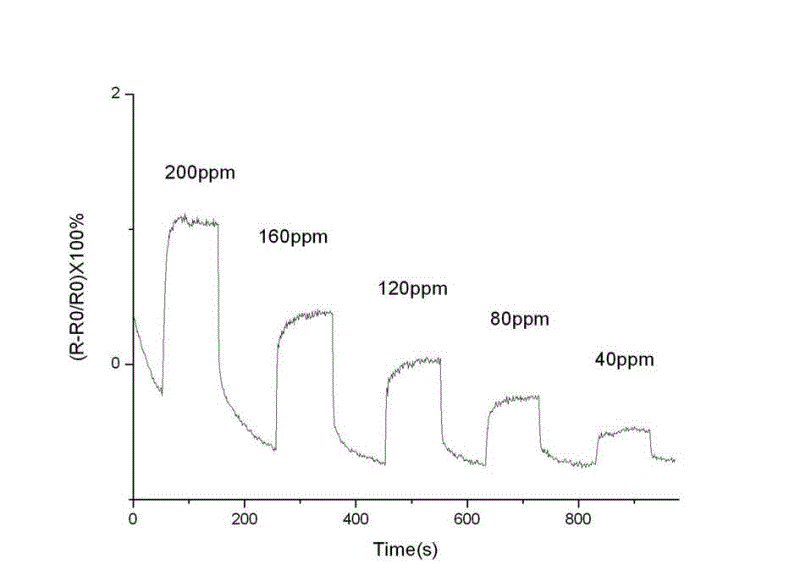

[0026] like figure 1 It shows that the golden fork finger electrode sensing function structure with a width and spacing of 40mm width and spacing is used on the silicon base plate. After that, the air spray technology is used to alternate the PEO sensitive film and multi -wall carbon nano -tube film on the surface of the substrate.After the residual solvents inside the sensitive membrane are volatilized, they will obtain a three -layer PEO and carbon nanotomay conductors.The sensor has a minimum detection limit of toluene steam reaching 0.2ppm and has a good baseline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com