General clamp piece for three-phase three-pole amorphous iron cores

A three-phase three-column, amorphous technology, used in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of backlog of components, high production cost, and many components, and achieve convenient operation and simple structure. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

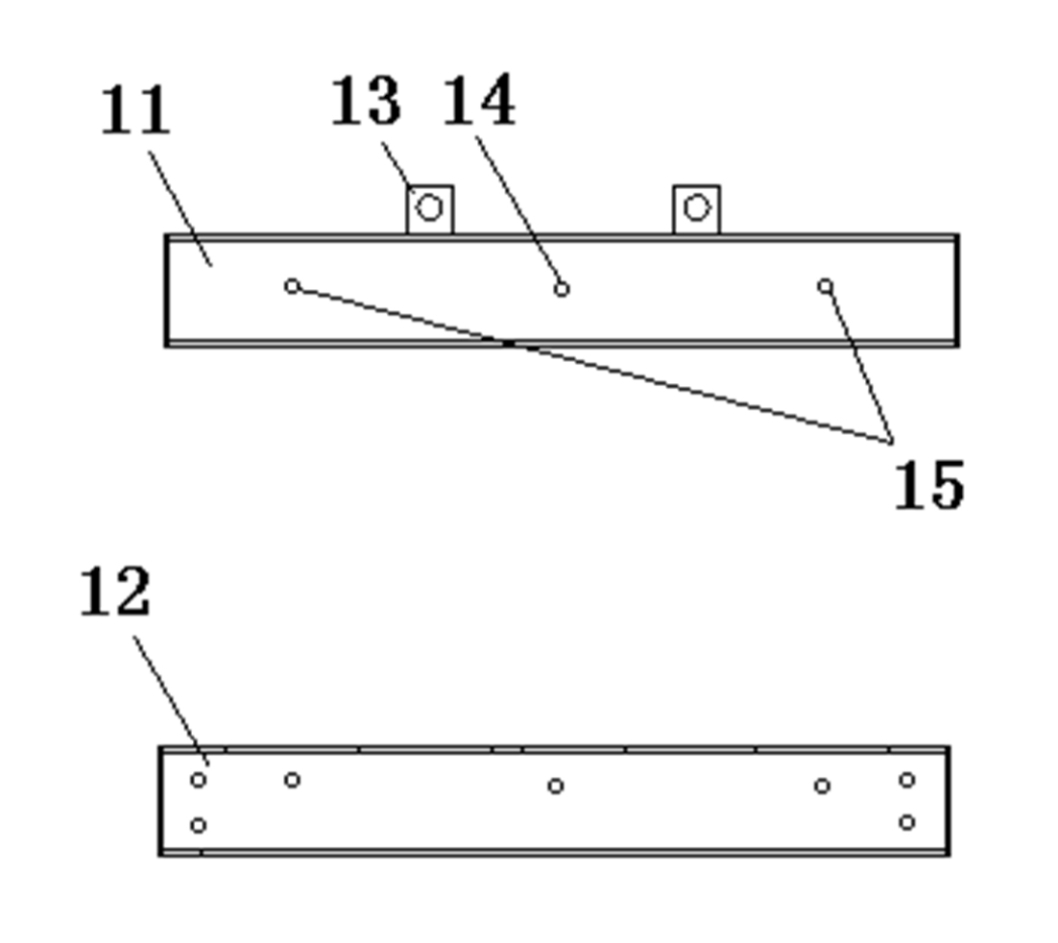

[0031] Example 1 (see attached Figure 4 and 5 ).

[0032] A three-phase three-column amorphous iron core universal clamp is composed of a horizontal strip-shaped upper clamp 21 and a lower clamp 22 . The upper clamping part 21 and the lower clamping part 22 are metal plates of grooved or non-troughed structure, and two lifting lugs are provided on the upper clamping part 21; A middle fixing pin hole 24 is set in the middle of the upper clamping piece 21 and a lower clamping piece 22 (both sides of the middle fixing pin hole 24 ) and side fixing pin slots 25 are set. Standard bolts can be used to clamp iron cores 36 of different sizes through the middle fixing pin hole 24 and the side fixing pin slots 25 . A clip can meet the requirements for manufacturing three-phase three-column amorphous iron cores of different sizes.

[0033] Why doesn't the present invention adopt a through groove structure on the upper clamping part 21 and the lower clamping part 22, isn't the vers...

Embodiment 2

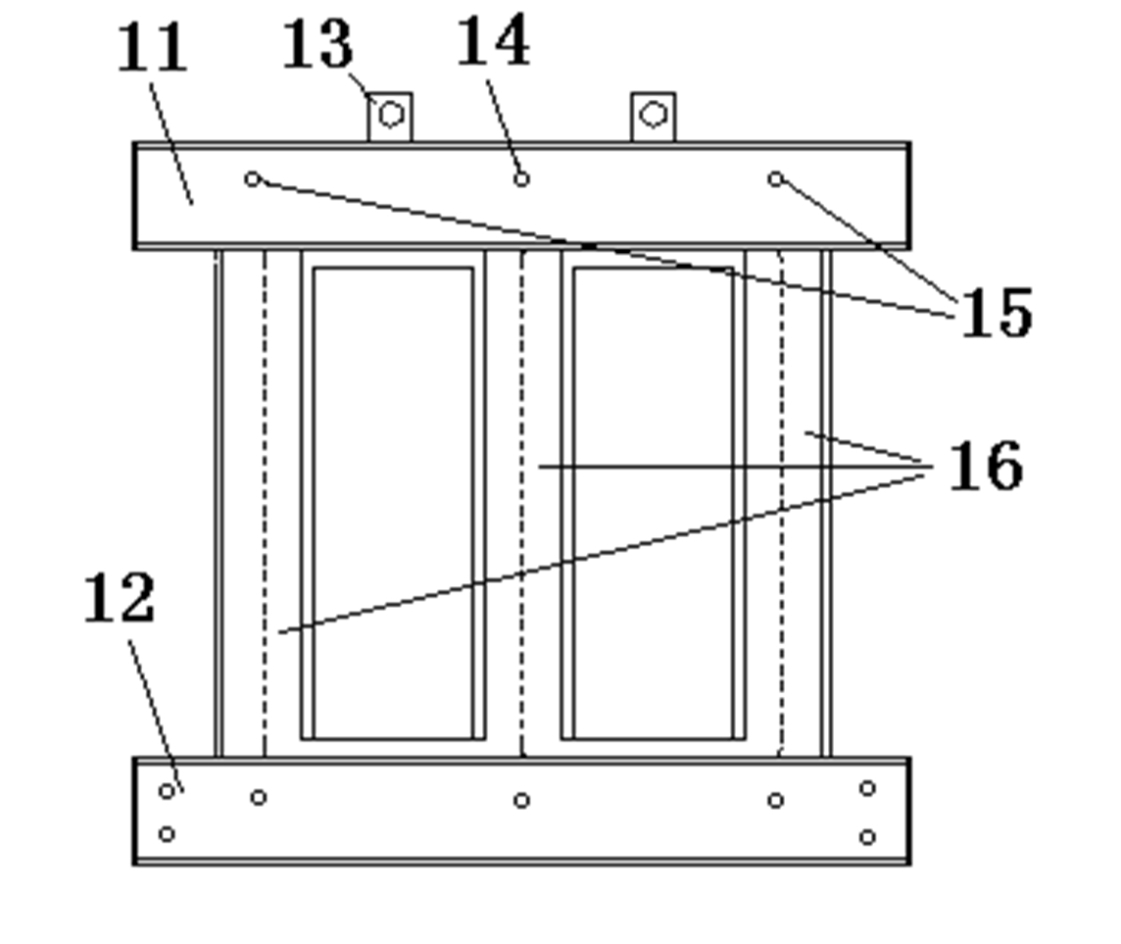

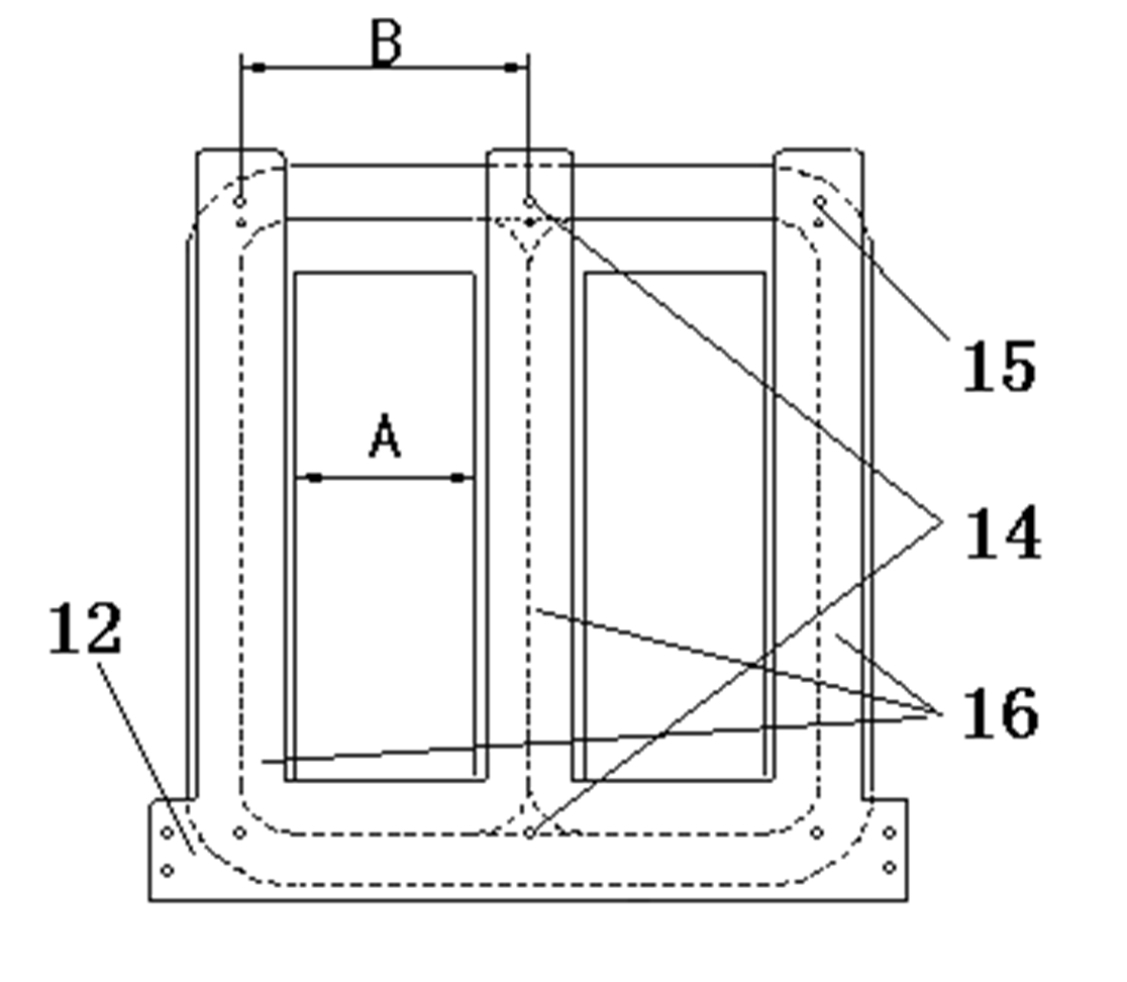

[0035] Example 2 (see attached Figure 6 and 7 ).

[0036] A three-phase three-column amorphous iron core universal clamp is composed of a horizontal strip-shaped upper clamp 31 and a lower clamp 32 . The upper clamping part 31 and the lower clamping part 32 are metal plates of grooved or non-troughed structure, and two lifting lugs are provided on the upper clamping part 31; The middle fixing pin hole 34 is set in the middle of the upper clamping piece 31 and the lower clamping piece 32 (both sides of the middle fixing pin hole 34) and there are 3 to 5 pin holes (if necessary, you can Increase some pin holes, generally 3~5 pin holes are just passable) the side fixed pin hole 35 that constitutes. The bolts of the standard parts can be used to clamp the iron cores 36 of different types through holes at different positions in the middle fixing pin hole 34 and the side fixing pin holes 35 . A clamp can meet the requirements for manufacturing various types of three-phase thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com