Rotationally decoupling two-degree freedom leveling mechanism

A technology of leveling mechanism and degrees of freedom, applied in the directions of manipulators, program-controlled manipulators, electrical components, etc., can solve the problems of slow loading of chips, long time required for leveling, etc., to achieve good dynamic effects, good motion performance, and bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

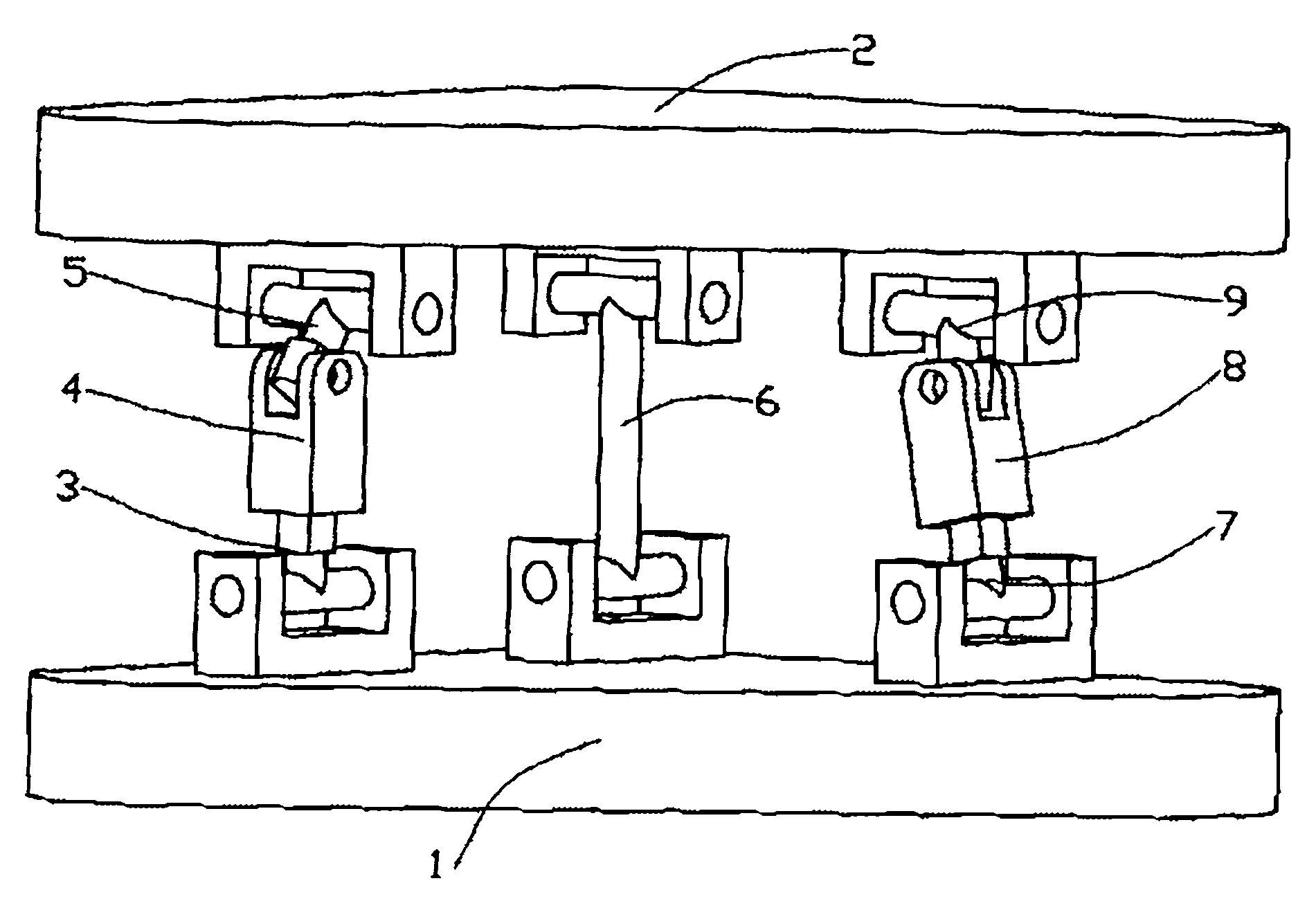

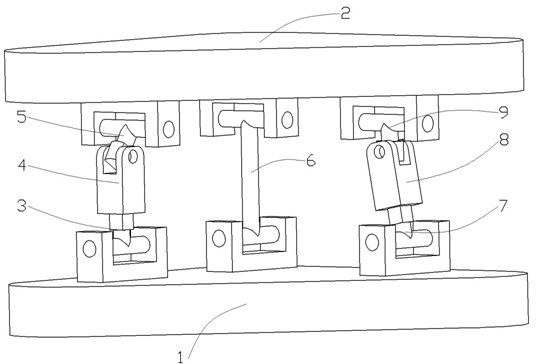

[0009] Such as figure 1 As shown, the leveling mechanism of the present invention mainly includes a fixed platform 1, a moving platform 2 and three branches connected between the two platforms. Wherein the first branch only includes a cross universal joint 6, and the two ends of the cross universal joint 6 are respectively connected with the fixed platform 1 and the moving platform 2 through rotating pairs, and the axes of the two rotating pairs are in different planes. The second branch is formed by connecting the rotating guide rail 3, the slide block 4 and the crank connecting rod 5 successively. Wherein the rotating guide rail 3 is connected with the fixed platform 1 through a rotating pair, and the axis of the rotating pair is collinear with the axis of the rotating pair connected with the cross universal joint 6 and the fixed platform 1; the slide block 4 is connected with the rotating guide rail 3 through a moving pair The moving direction of the moving pair is not par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com