Power diode

A power diode and base technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to reduce substrate leakage, avoid punch-through, and improve reverse withstand voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

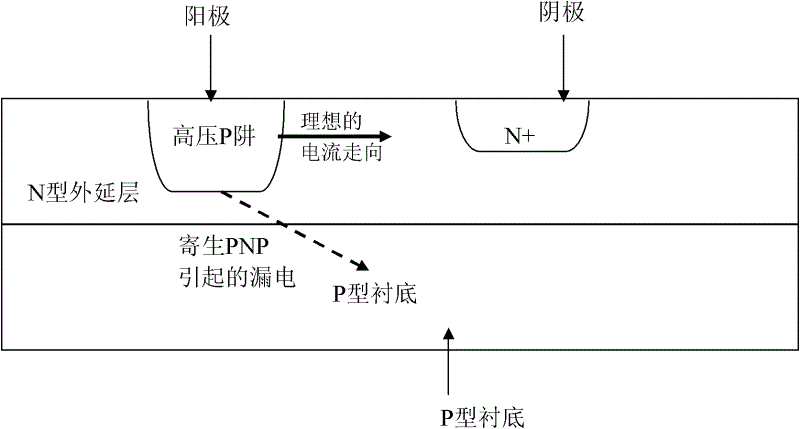

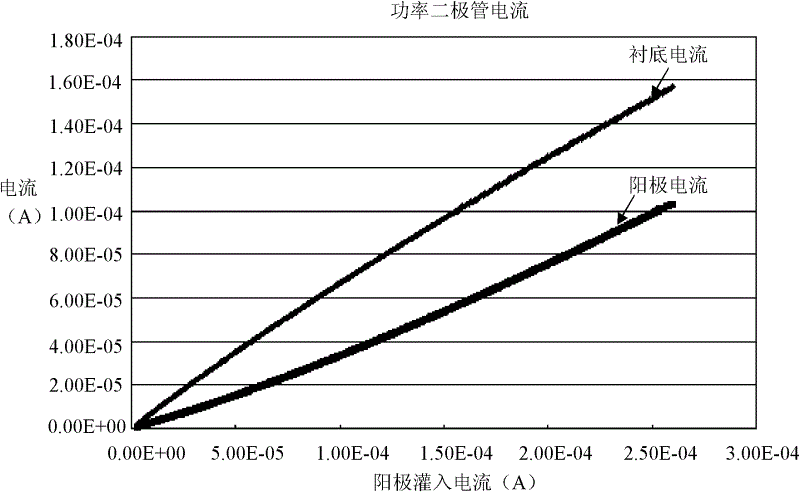

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

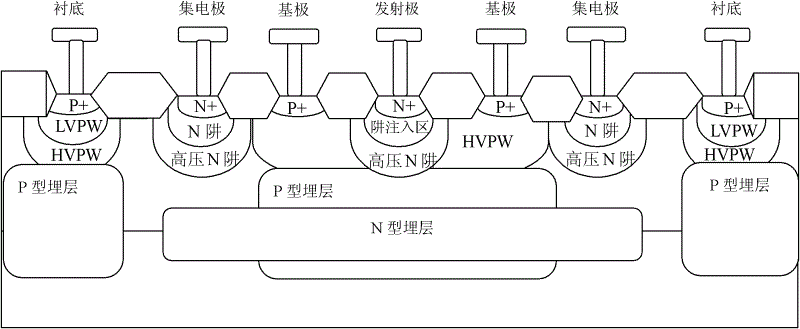

[0016] In the power diode of the NPN structure of the present invention, the base and the collector in the NPN structure are connected as the anode of the power diode, and the emitter is used as the cathode of the power diode. On the basis of the existing NPN structure, a well injection region is added under the emission region of the emitter end. The conductivity type of the well injection region is the same as that of the emission region, but the impurity concentration is lower than that of the emission region, which is used to improve the device. reverse withstand voltage. In order to prevent the punch-through problem between the collector and the emitter, a buried layer is provided on the substrate below the base. The conductivity type of the buried layer is the same as that of the base region, but the impurity concentration is higher than that of the base region (see Figure 4 and Figure 5 ). by Figure 5 For example, the impurity concentration of the P-type buried la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com