Luminescent module

A technology of light-emitting modules and light-emitting parts, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as the inability to change the color temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

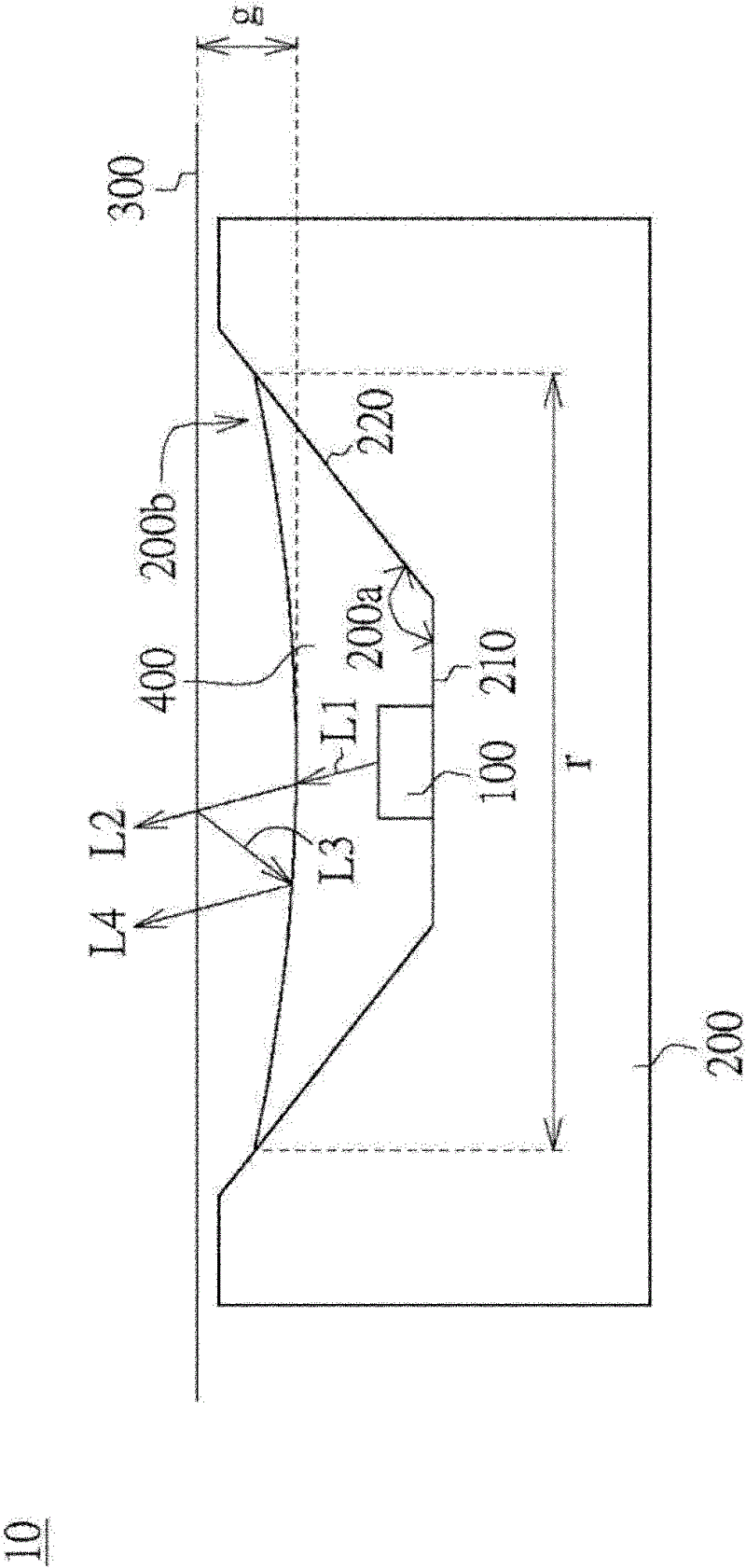

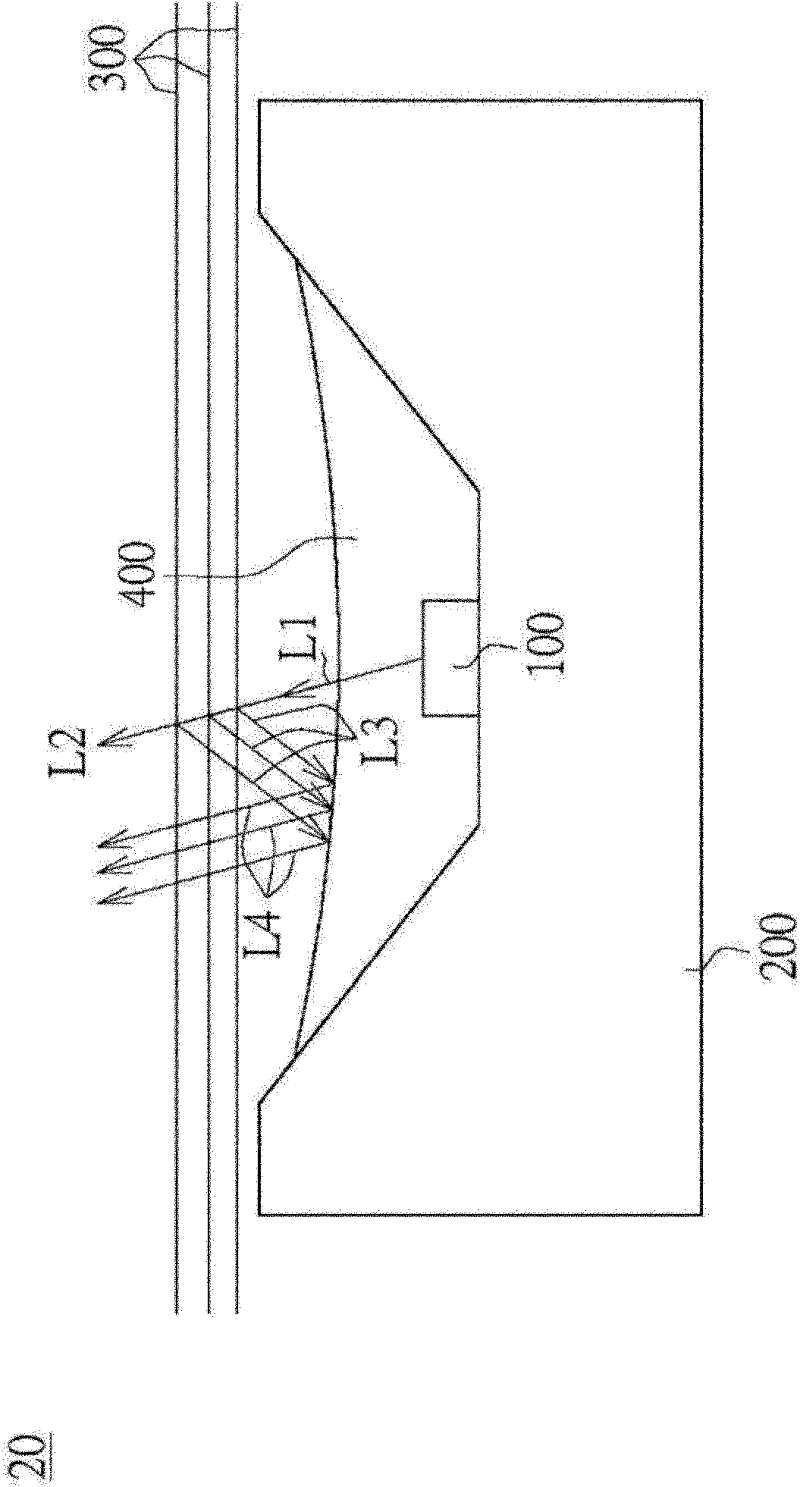

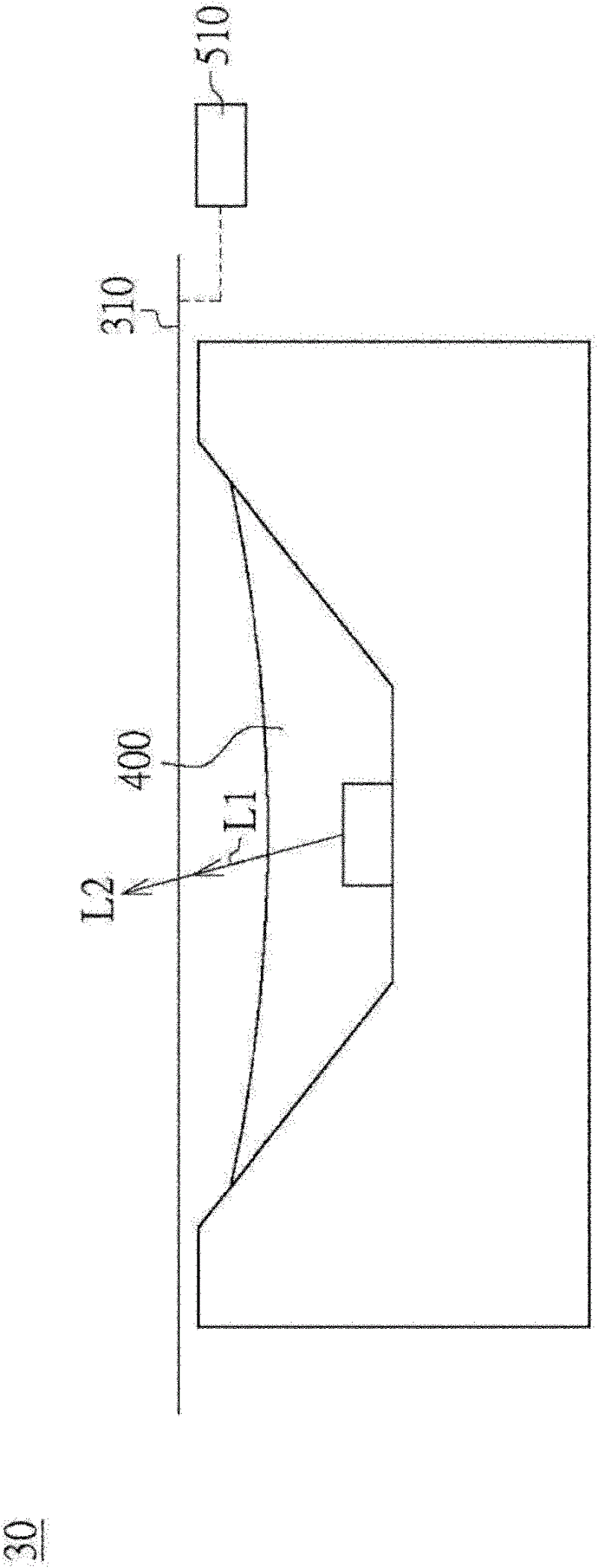

[0024] Please refer to figure 1 , which is a schematic diagram of a light emitting module according to a preferred embodiment of the present invention. The light emitting module 10 includes a light emitting element 100 , a substrate 200 , a thin film 300 and a phosphor layer 400 . The light emitting element 100 is, for example, a light emitting diode (LED) for emitting a light L1. The substrate 200 is, for example, a LED packaging substrate. The light emitting element 100 is disposed on the substrate 200 . The film 300 can be, for example, a diffusion film or a semi-transmissive and semi-reflective film. Part of the light L1 can pass through the film 300 to be the light L2 , and part of the light L1 can be reflected or scattered by the film 300 to be the light L3 . The phosphor layer 400 is disposed between the light emitting element 100 and the film 300 . The phosphor layer 400 is used to change the wavelength of the light L3 reflected by the film 300 . The light-emitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com