Method for improving heat dissipation and luminous performance of LED filament lamp by using helium gas

A technology for LED filament lamps and luminous performance, which is applied to semiconductor devices of light-emitting elements, light sources, lighting and heating equipment, etc. warm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The invention provides a method of using helium to improve the heat dissipation and luminous performance of LED filament lamps, specifically:

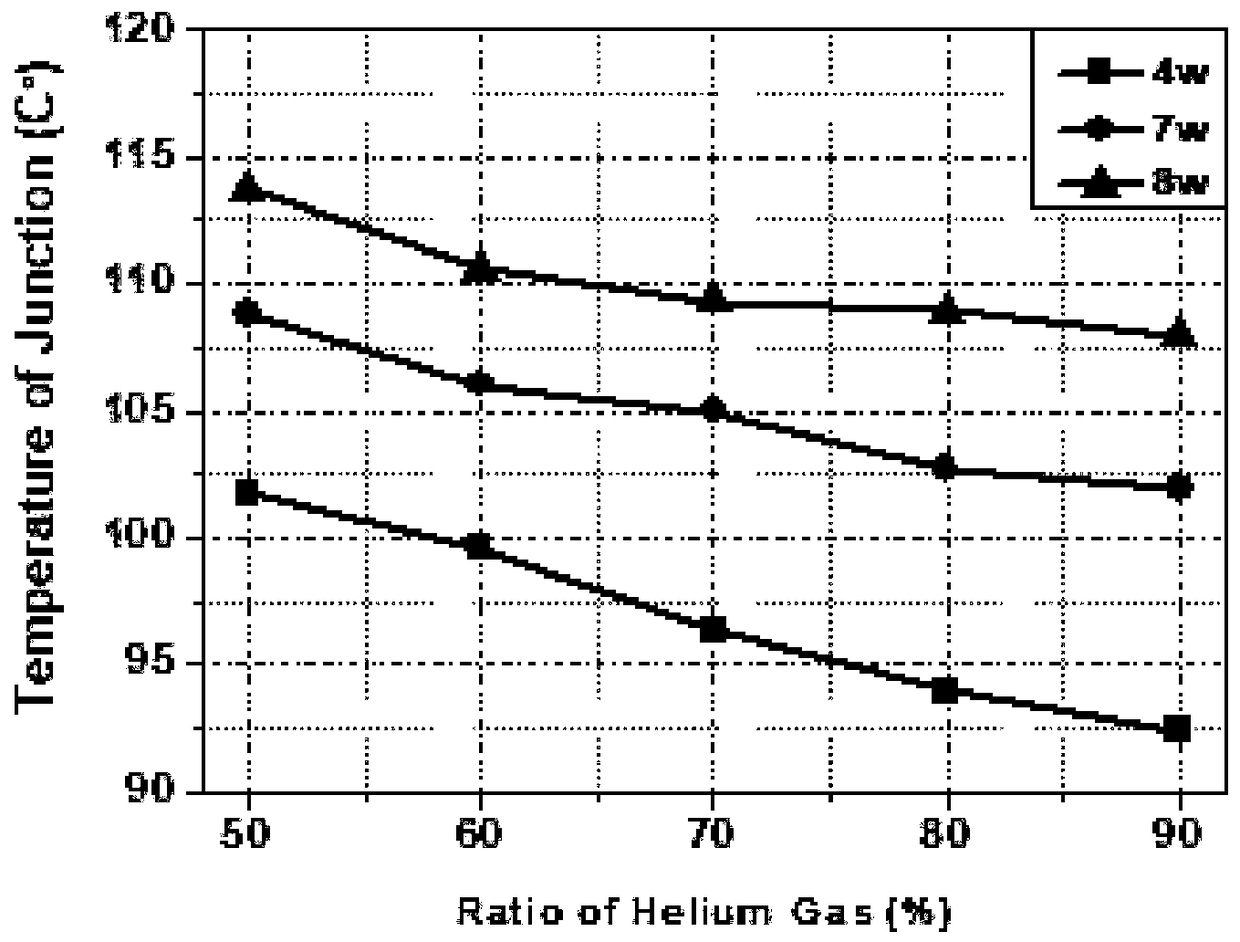

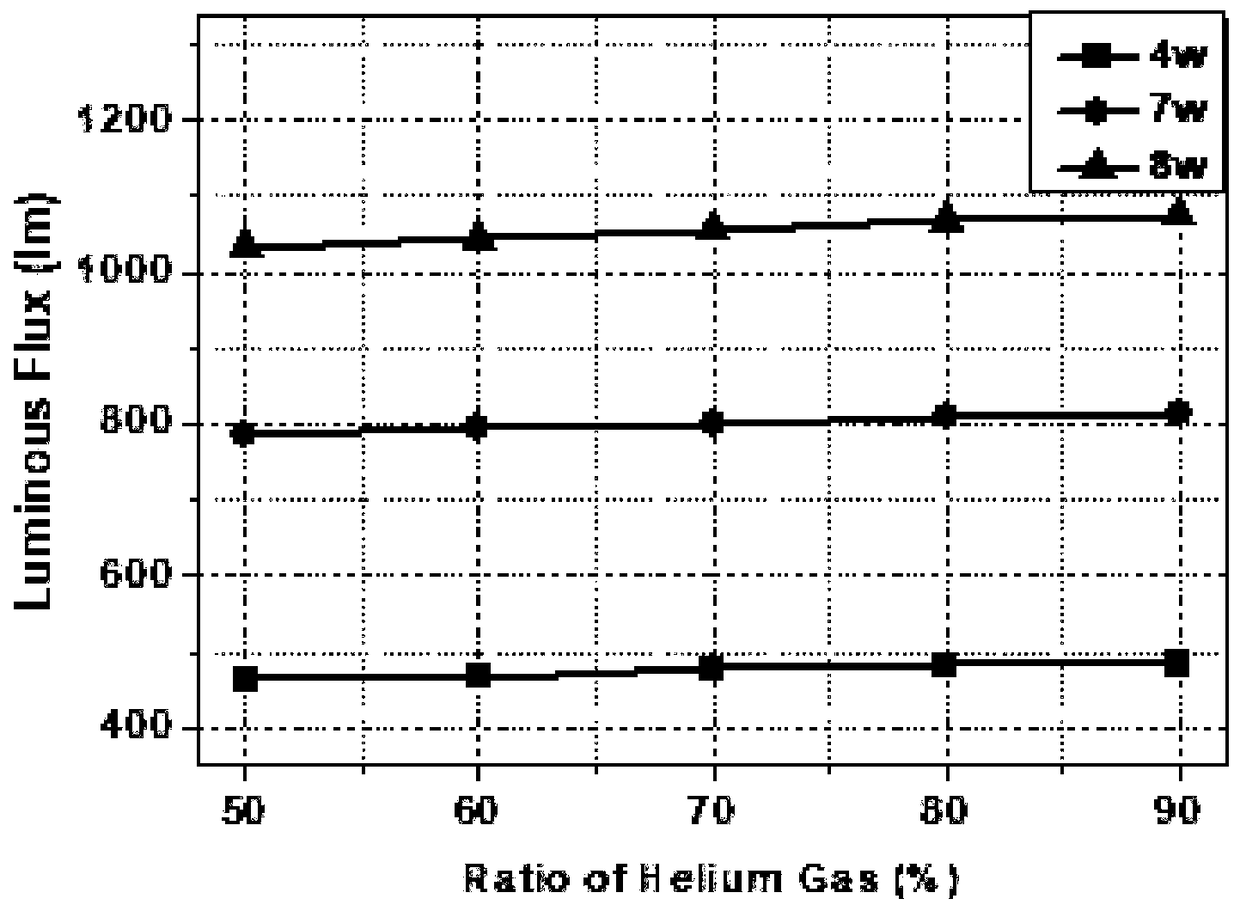

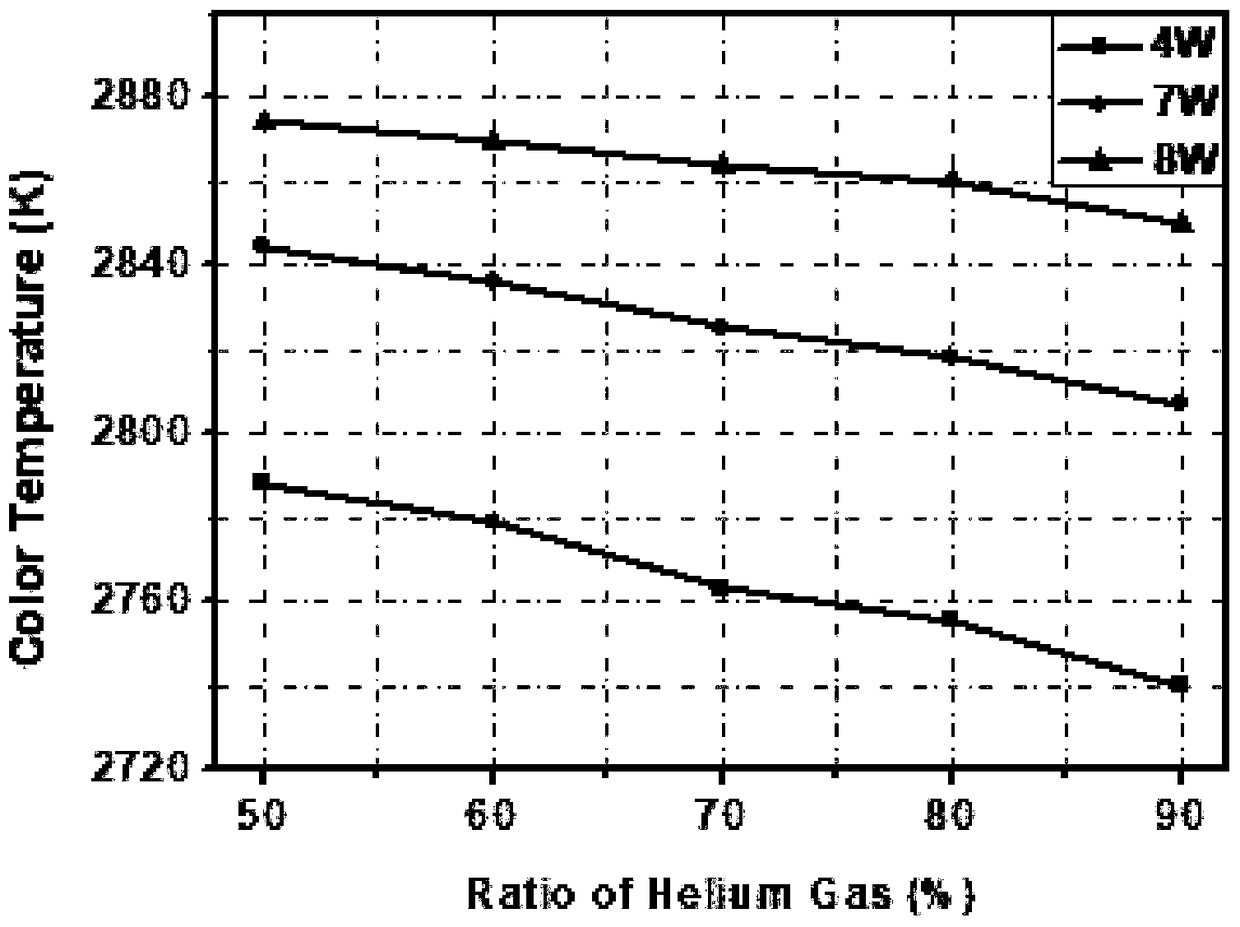

[0021] Fill the LED lamp cavity with 50%-90% helium, and detect the junction temperature and luminous flux of the LED lamp in real time.

[0022] In the entire LED bulb shell, when the helium gas flows through the high-temperature working LED light bar, the heat will be transferred from the light bar to the helium gas, and the density of the heated helium gas is lower than that of the helium gas with a lower surrounding temperature. So it expands and rises, transfers heat to the glass bulb at the bulb, then cools and sinks, and starts the next cycle. During the whole process, the heat conduction of the gas follows Fourier's law;

[0023] Convective heat transfer refers to the energy exchange that o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com