Multiphase motor control system based on driving of multiphase matrix converter

A multi-phase matrix and multi-phase motor technology, applied in the field of electric transmission, can solve problems such as low power factor, inability to flow bidirectionally, increase in volume and weight, etc., achieve high-precision speed regulation performance, improve efficiency, and reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

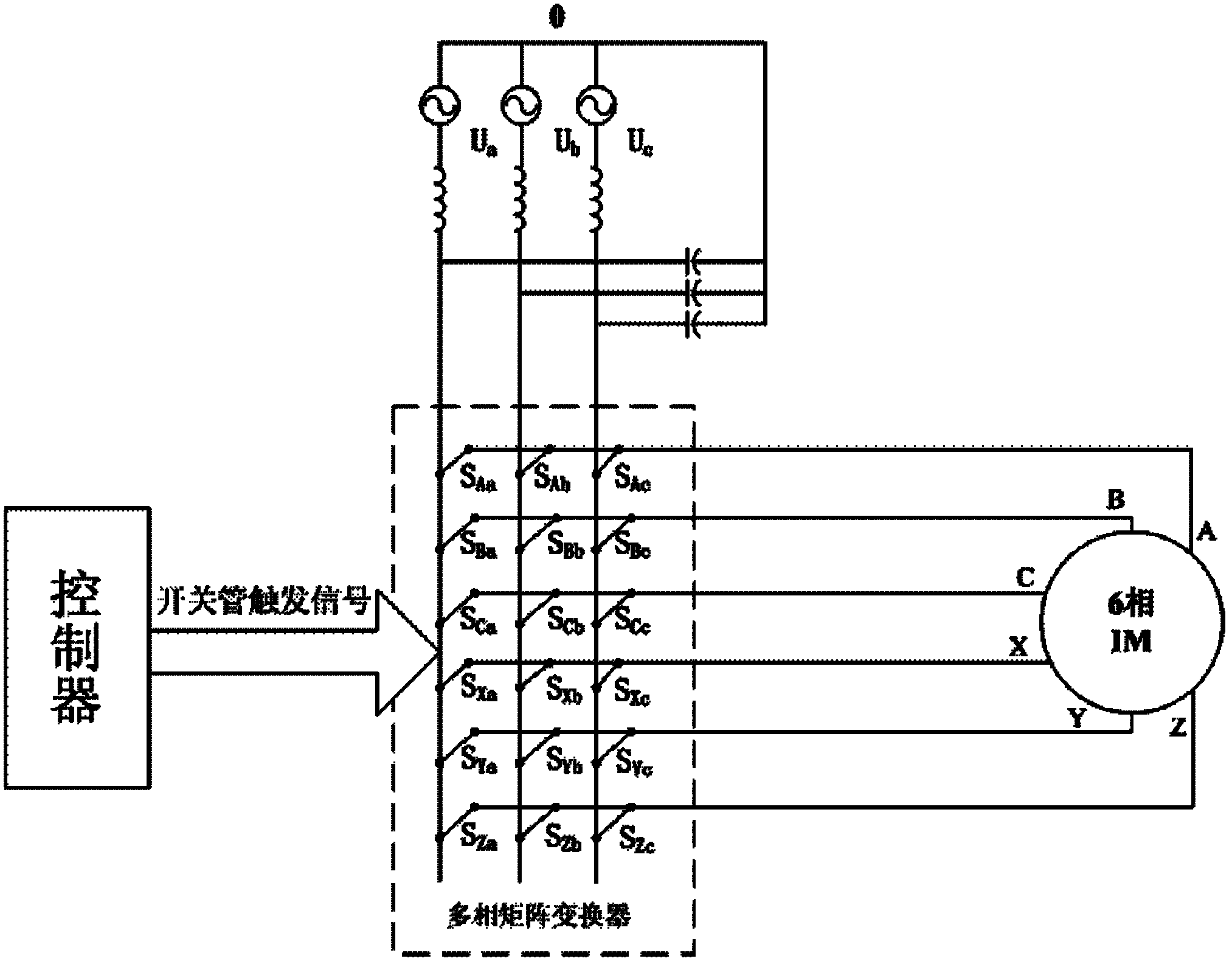

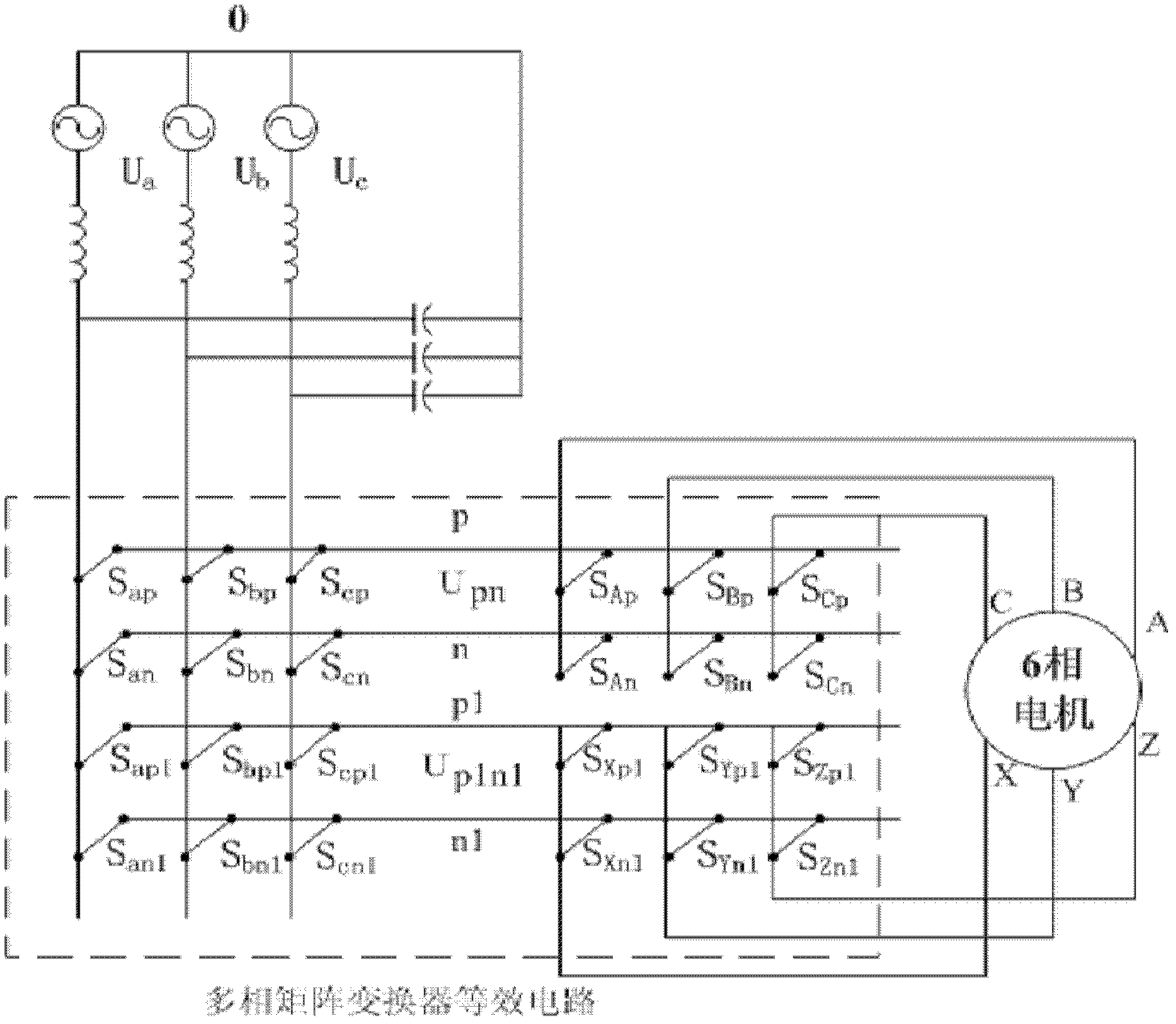

[0023] Embodiment: The present invention takes a six-phase motor as an example to describe a multi-phase motor control system driven by a multi-phase matrix converter. The structure and working principle of the entire system will be explained in detail below with reference to the accompanying drawings.

[0024] refer to figure 1 , a multi-phase motor control system driven by a multi-phase matrix converter, including a multi-phase matrix converter, the multi-phase matrix converter consists of 18 bidirectional switch tubes to form a 3×6 multi-phase matrix converter, the input side is connected with the three The phase AC power supply is connected, the output side is connected with the multi-phase motor, and the on and off of each switch tube is controlled by the trigger pulse signal sent by the control.

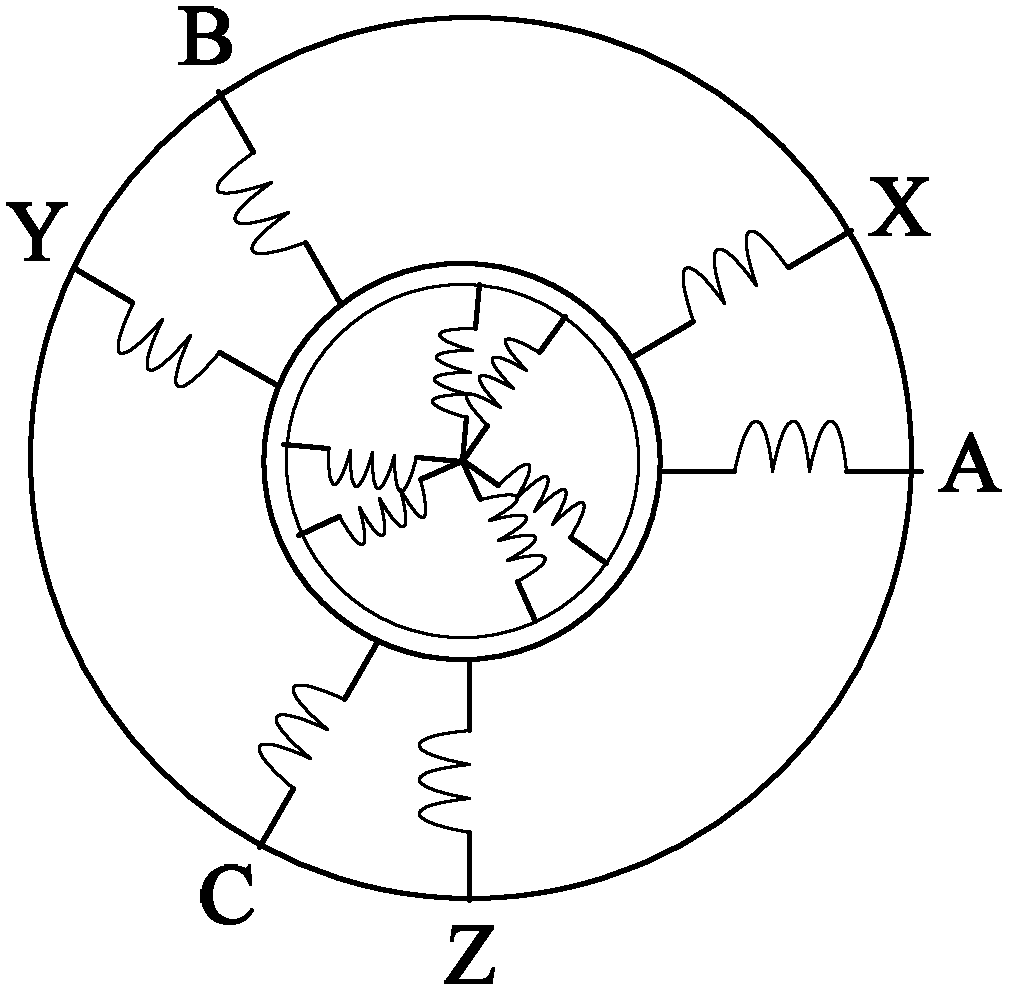

[0025] refer to figure 2 , figure 2 for figure 1 The structure diagram of the six-phase motor shown in , the six phases of the six-phase motor are ABC, XYZ, and the differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com