Combination structure of mechanical arm sliding table and guide beam

A combined structure and manipulator technology, applied in the field of manipulators, can solve the problems of environmental impact on the work site, increase the labor intensity of workers, and increase the cost of equipment use, so as to reduce the maintenance intensity and use cost, improve the effect of smooth motion, and reduce maintenance. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

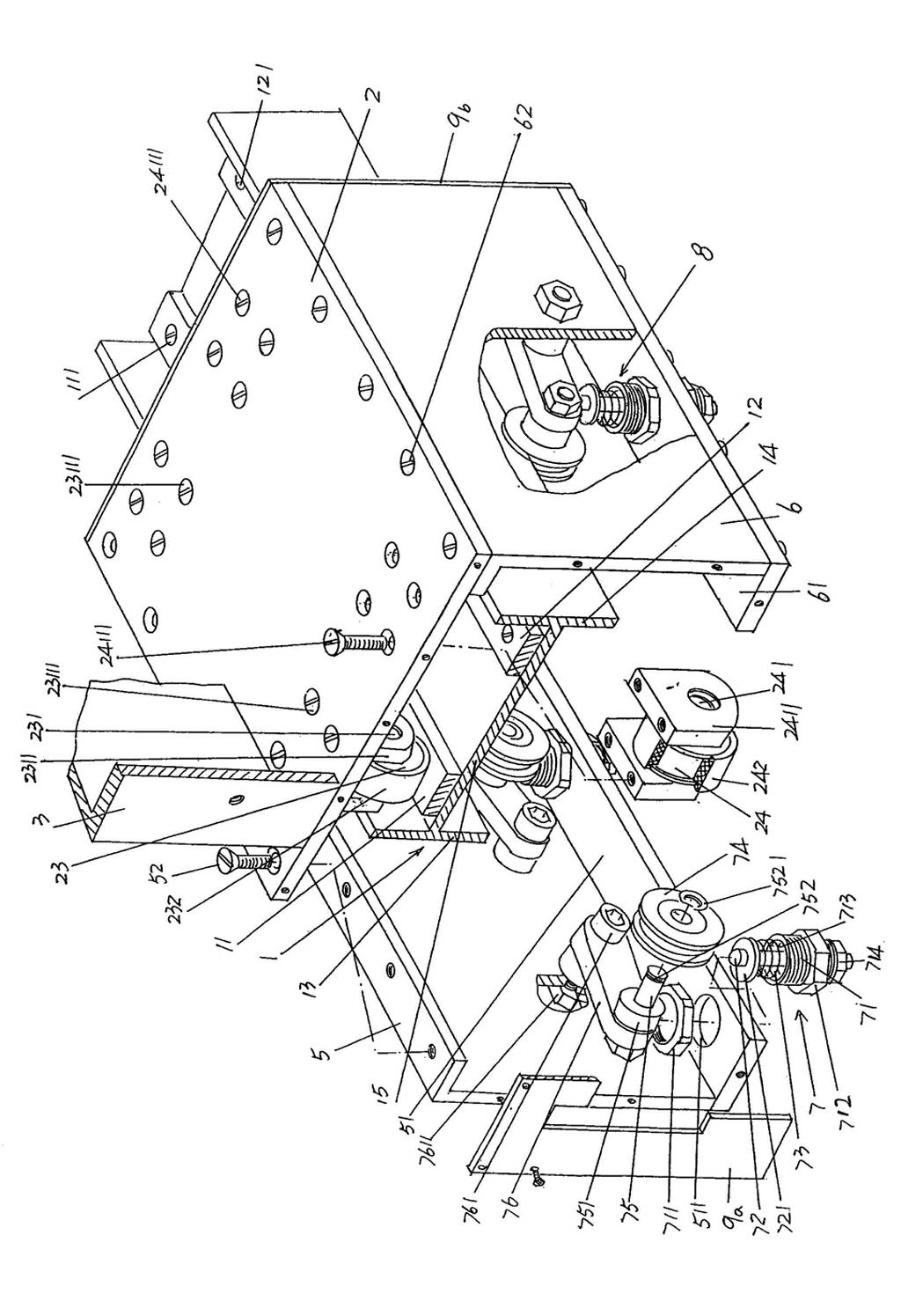

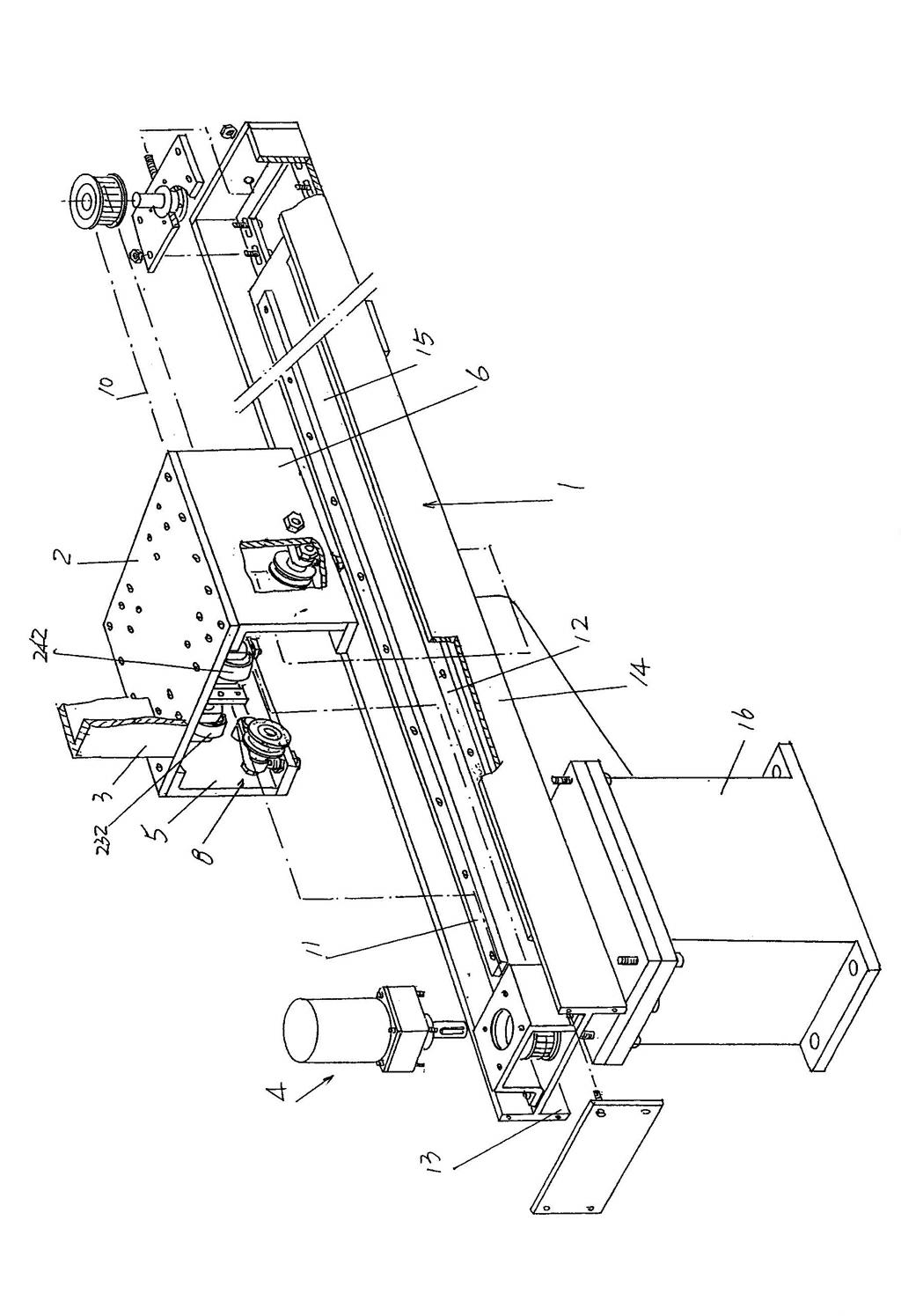

[0026] Please see figure 1 , a guide beam 1 is provided, and the guide beam 1 is composed of first and second side walls 13, 14 and a bottom wall 15 between the first and second side walls 13, 14 to form an H-shaped cross-sectional shape The shape, that is, the guide beam 1 adopts H-shaped steel. The side of the guide beam 1 facing upward in the state of use, more specifically, the side of the bottom wall 15 facing the surface of the slide table 2 to be described below is fixed with a first guide rail 11 with a first screw 111, and the other side is fixed with a first screw 111. The second screw 121 fixes a second guide rail 12, and the first and second guide rails 11, 12 are parallel to each other.

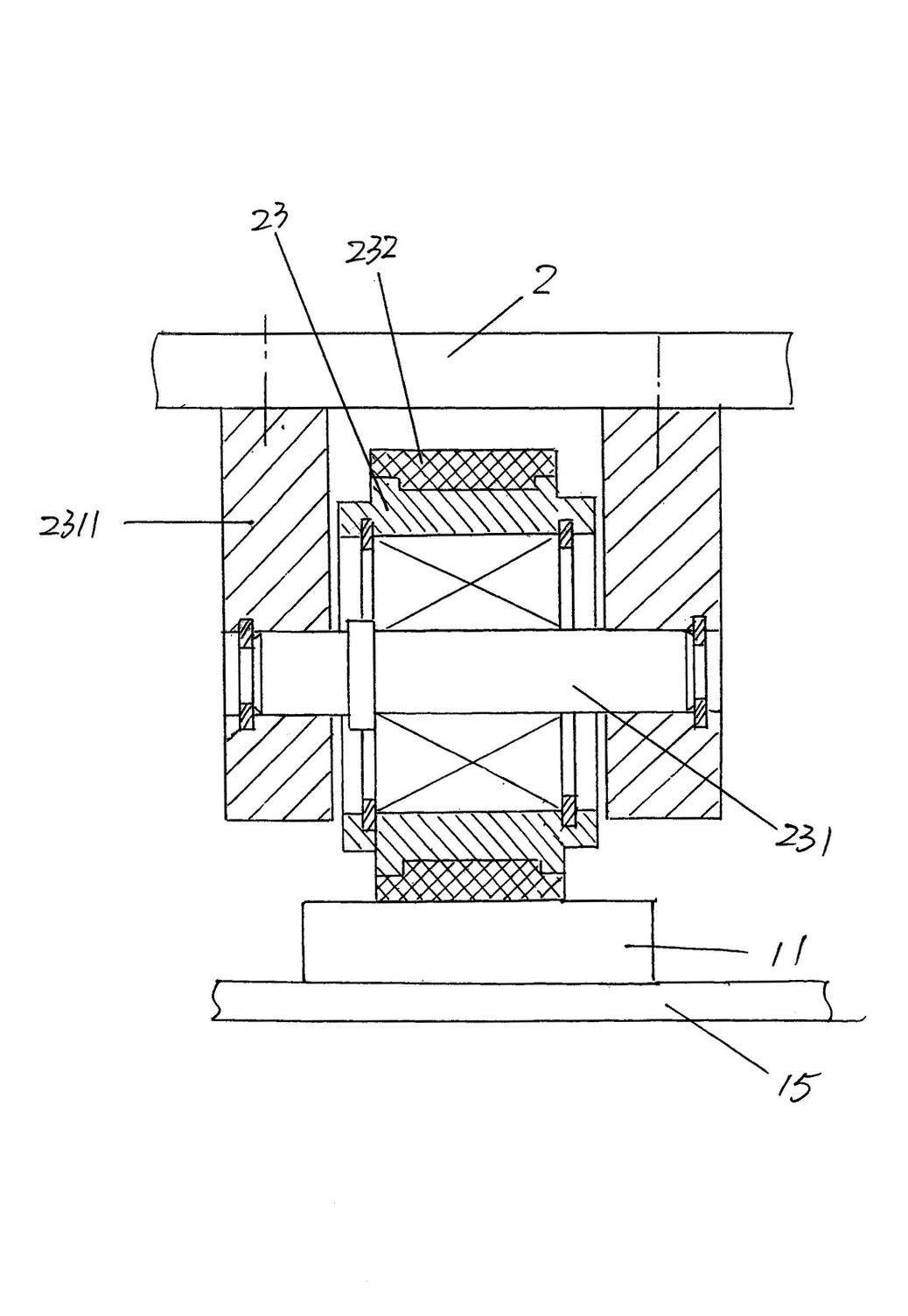

[0027] A slide table 2 that can be either rectangular parallelepiped or square and flat is matched with the aforementioned guide beam 2, specifically: on the side of the slide table 2 facing the guide beam 1 and on the side corresponding to the first guide rail 11 A pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com