Perfecting press

A printing machine and double-sided technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of insufficient paper deformation, ink ghosting, etc., achieve good reducibility, clear dots, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

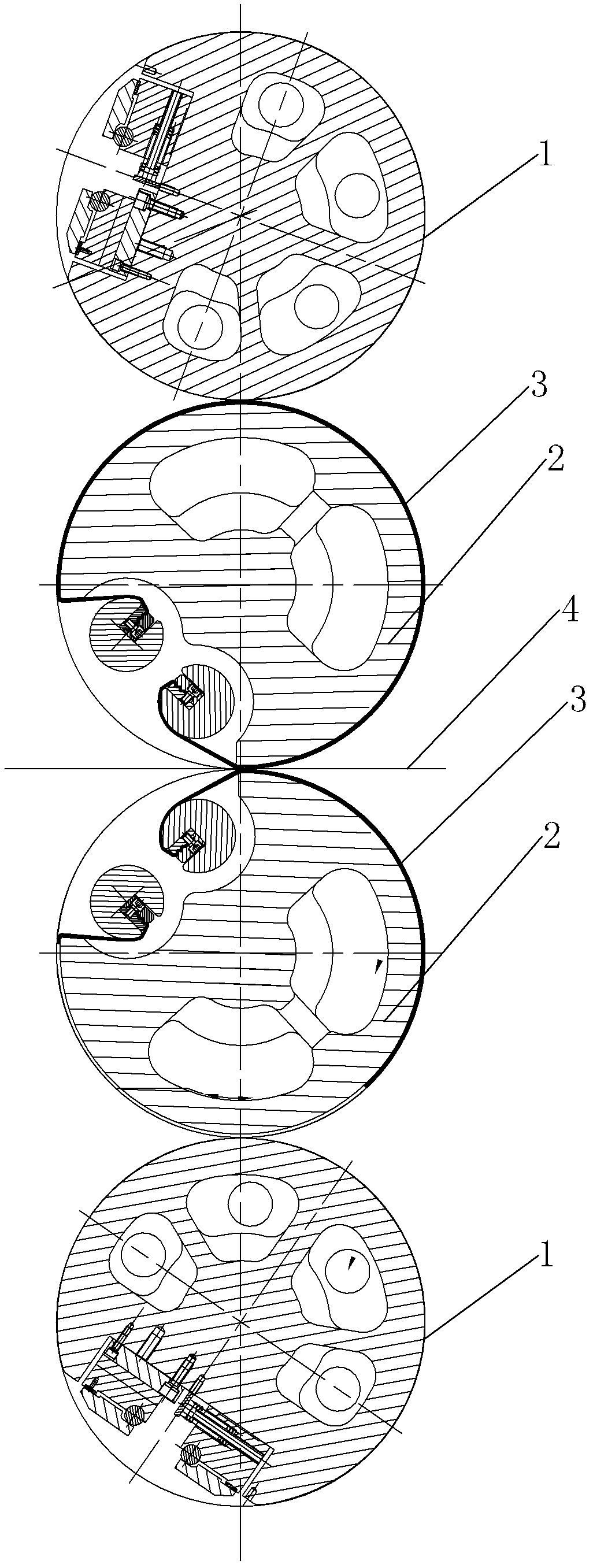

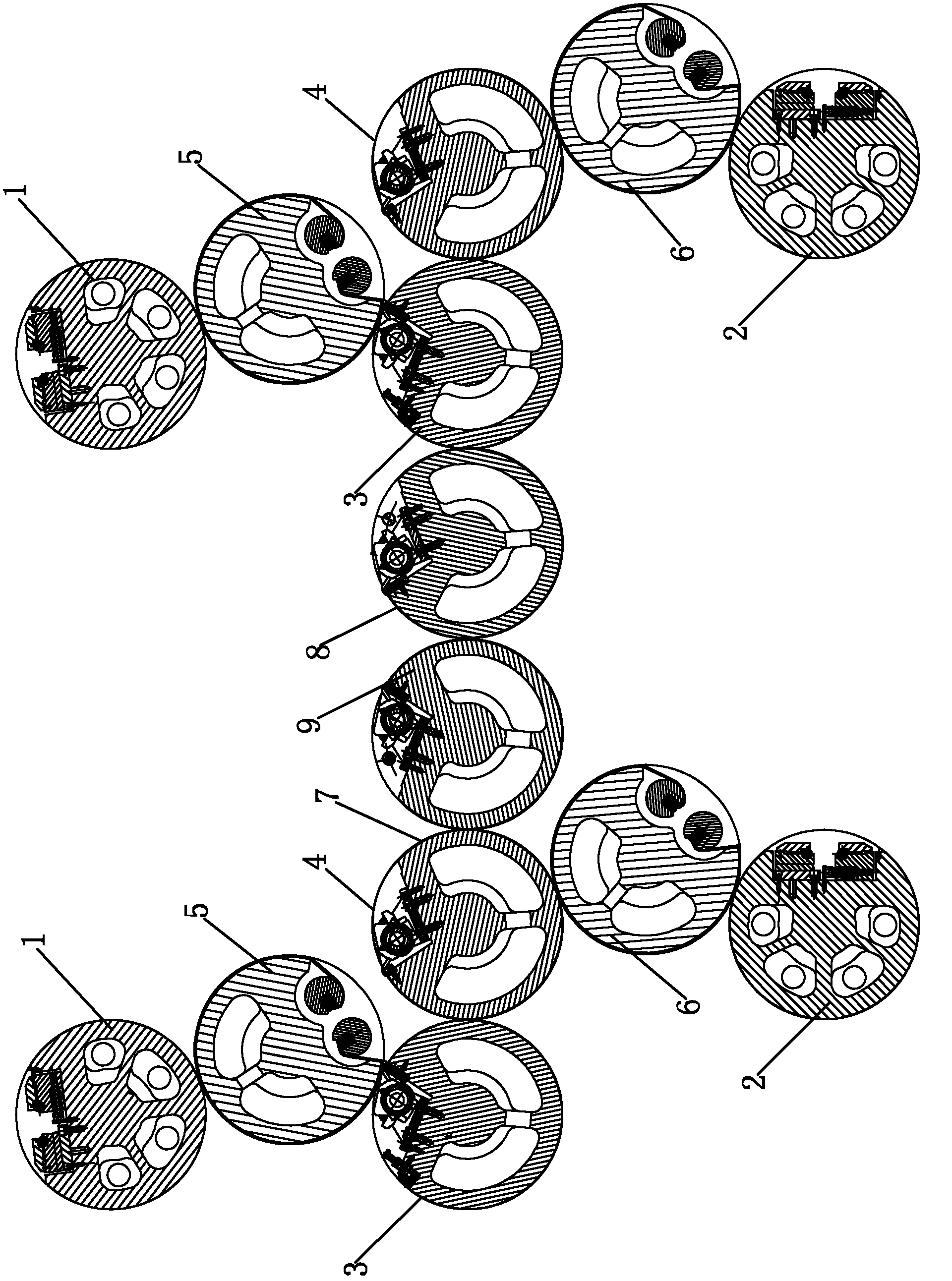

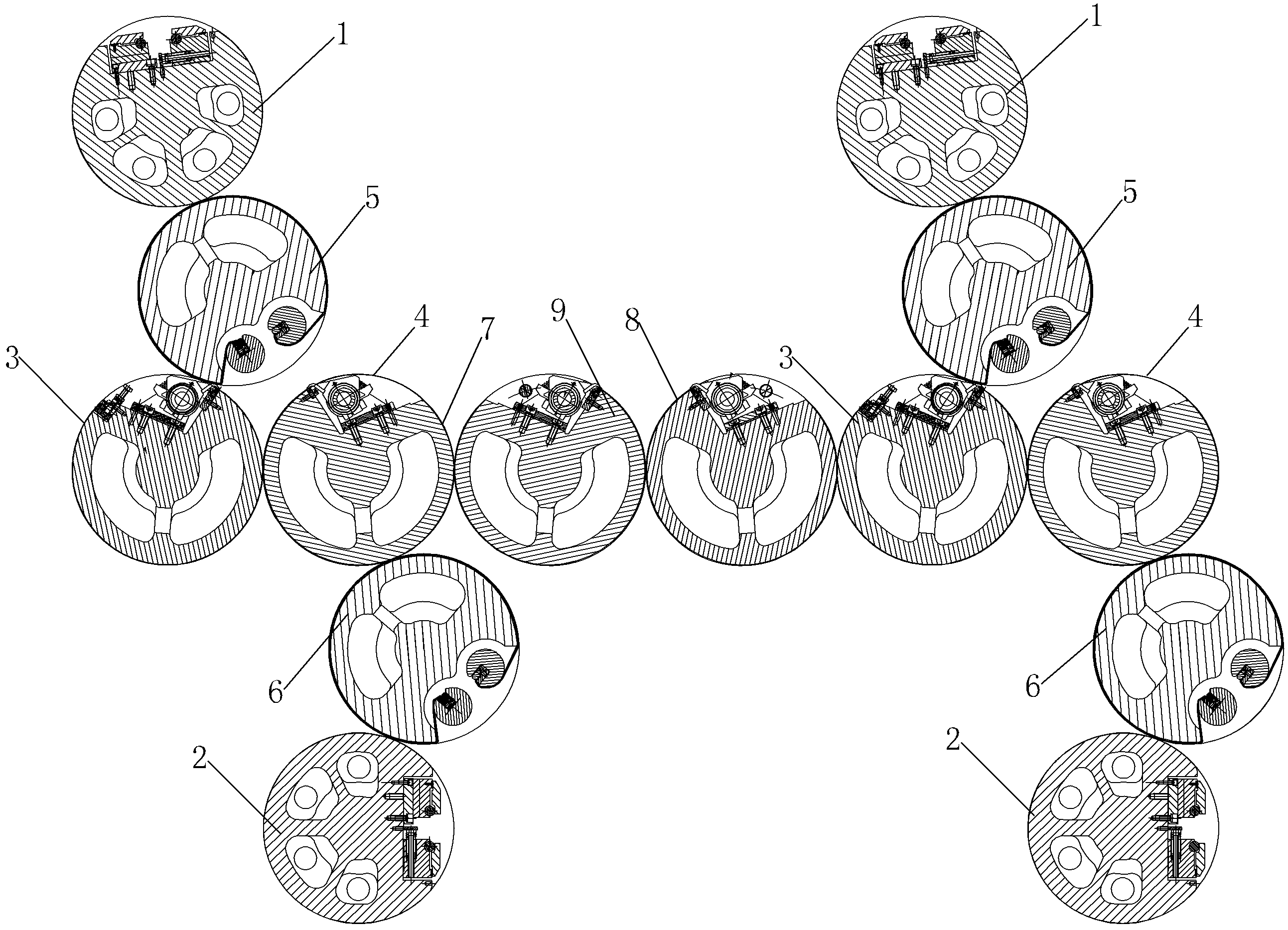

[0014] Embodiment: a kind of duplex printing machine, as figure 2 As shown, the printing machine includes two color groups, left and right, and each color group includes upper and lower plate cylinders 1, 2, upper and lower impression cylinders 3, 4 and upper and lower blanket cylinders 5, 6, The upper blanket cylinder 5 is arranged between the upper plate cylinder 1 and the upper impression cylinder 3, and the upper blanket cylinder 5 cooperates with the upper plate cylinder 1 and the upper impression cylinder 3 respectively; the lower blanket cylinder 6 is arranged on the lower plate cylinder 2 and the lower impression cylinder 4, and the lower rubber cylinder 6 cooperates with the lower plate cylinder 2 and the lower impression cylinder 4 respectively, and the upper and lower impression cylinders 3 and 4 are coated with anti-sticking Ink ceramic coated stainless steel metal plate 7, and there is a gap for paper to pass between the upper impression cylinder 3 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com