Oblique square wave shaped dislocated stacking adobe pile on adobe vehicle and automatic stacking method thereof

A technology of adobe and oblique square, which is applied in the automatic stacking device of brick making machine and its automatic stacking field, can solve problems such as brick adobe collapse, achieve the effect of improving the overall rigidity and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

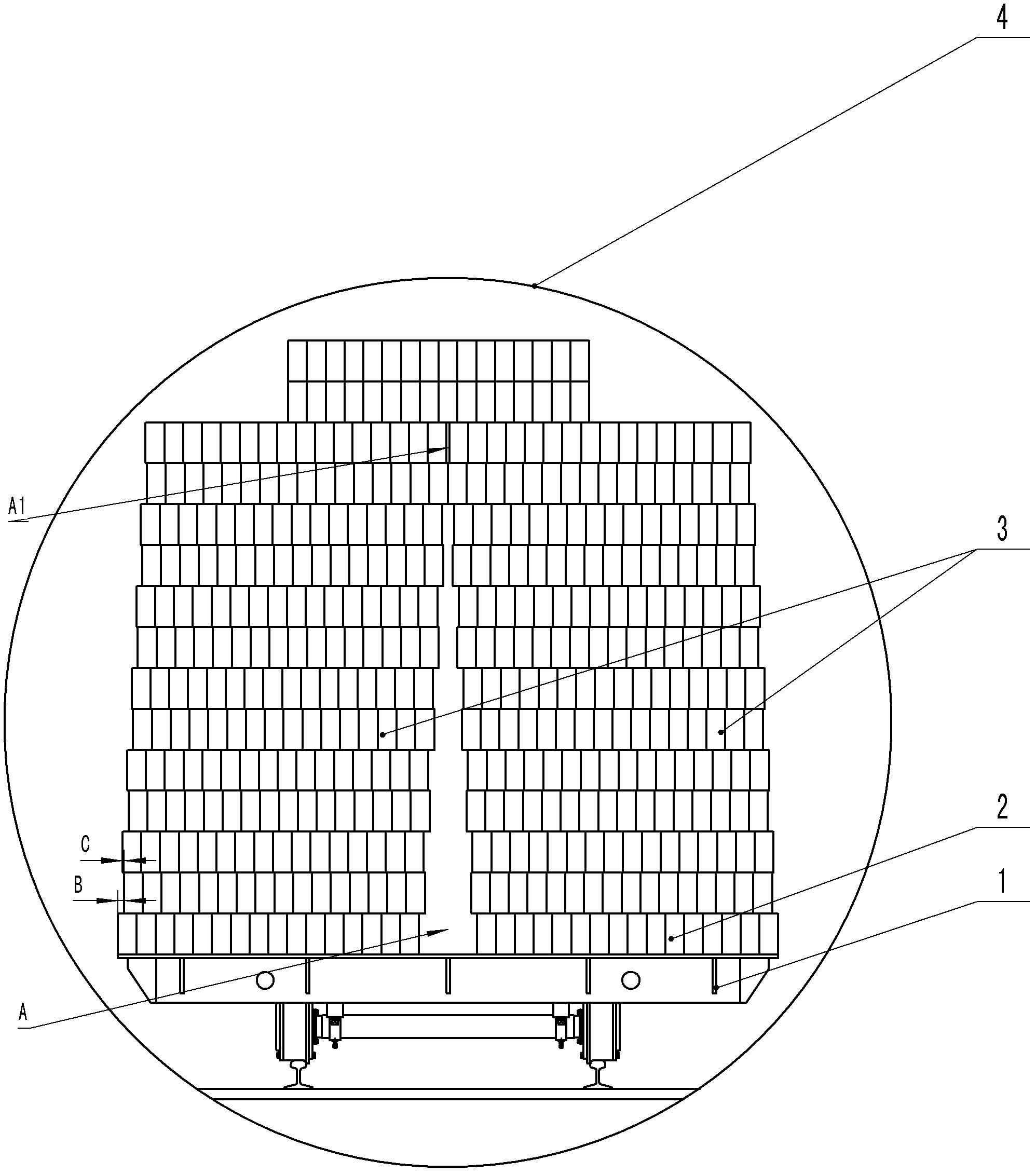

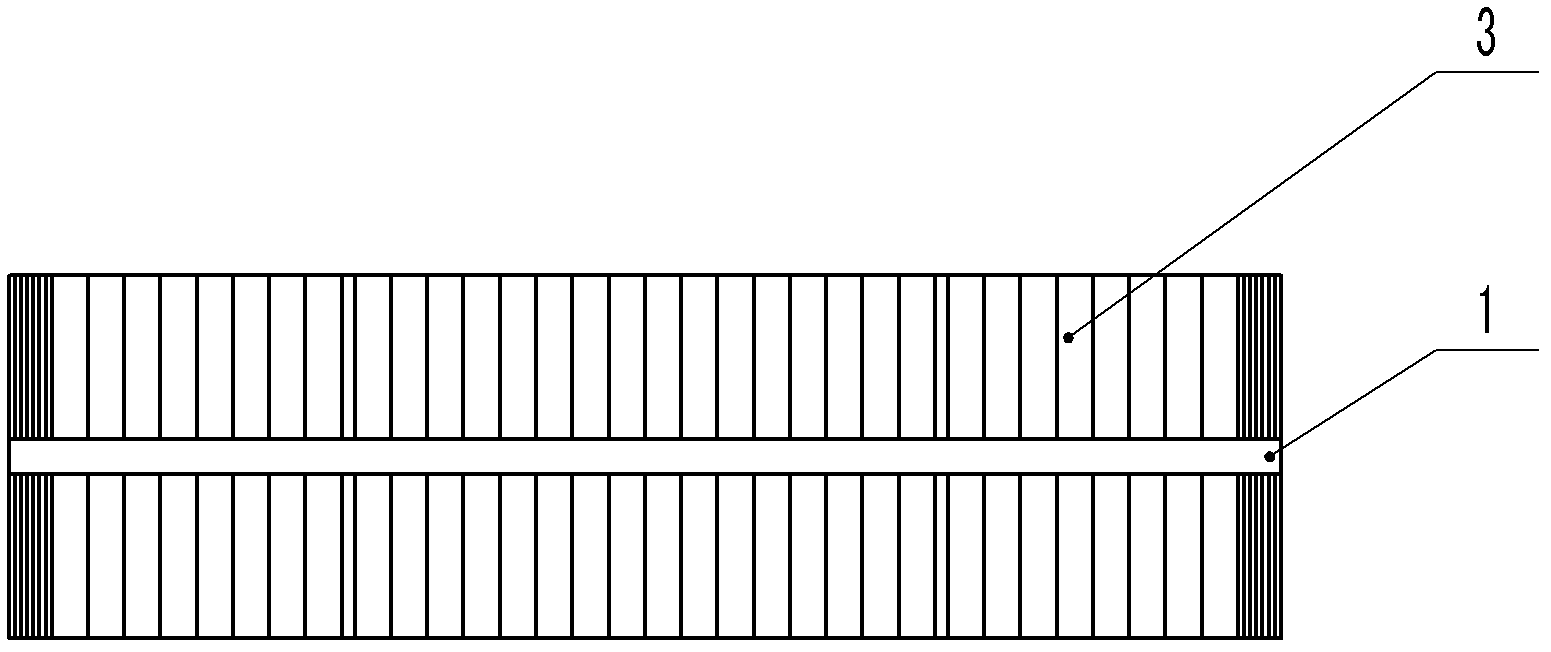

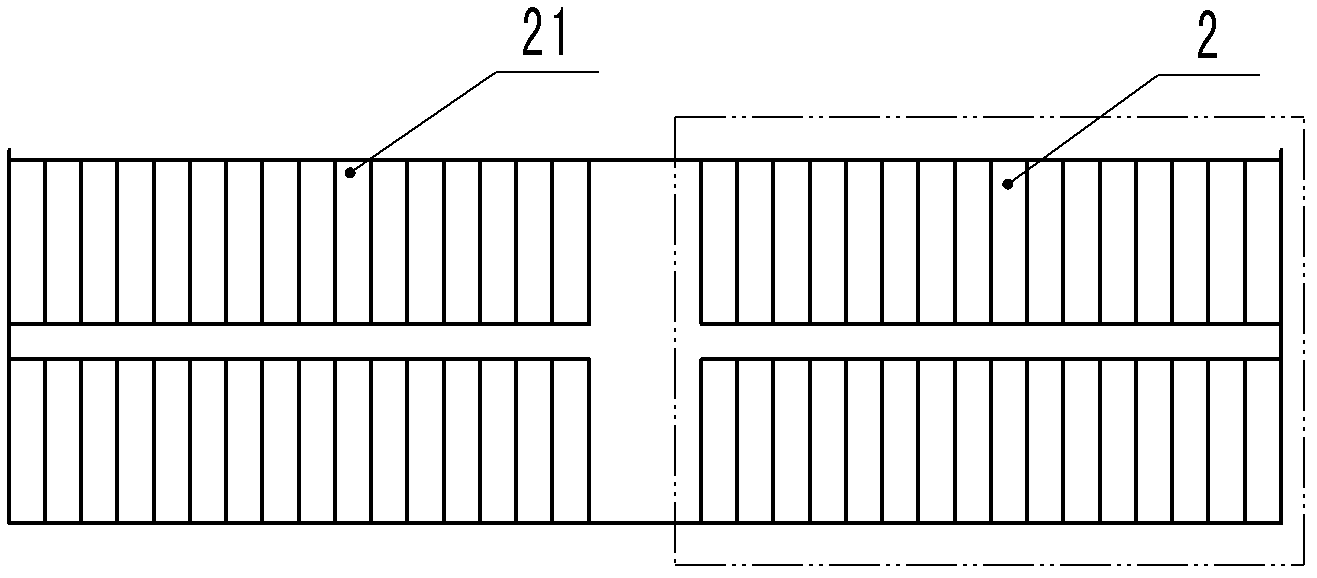

[0045] Such as figure 1 , figure 2 , image 3As shown, there is an oblique square wave dislocation pile of adobe piles 3 on the blank car 1. There are two square rows of adobe piles 3 distributed along the length direction of the adobes on the blank car 1. There are two piles of adobe piles 3 in each square row of adobe piles. bricks, each square stack of bricks is formed by stacking several layers of brick squares 2, the bricks in the brick squares 2 stand sideways, and the two square bricks 2 are placed on the brick car 1 successively to form each The first layer of adobes in the square array stack of adobes, the two square arrays are relatively distributed along the thickness direction of the side-standing adobes, with a distance A between them, and a total of four adobes are placed in the square matrix 2 to form the adobe car 1 and the adobe pile 3 The first layer of adobe phalanx 211. Based on the square matrix 211 of the first layer of adobes, stack adobes layer by l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com