Ink composition and printed matter

一种油墨组合物、组合物的技术,应用在印刷、油墨、运输和包装等方向,能够解决图像耐气体性低、很难喷出等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

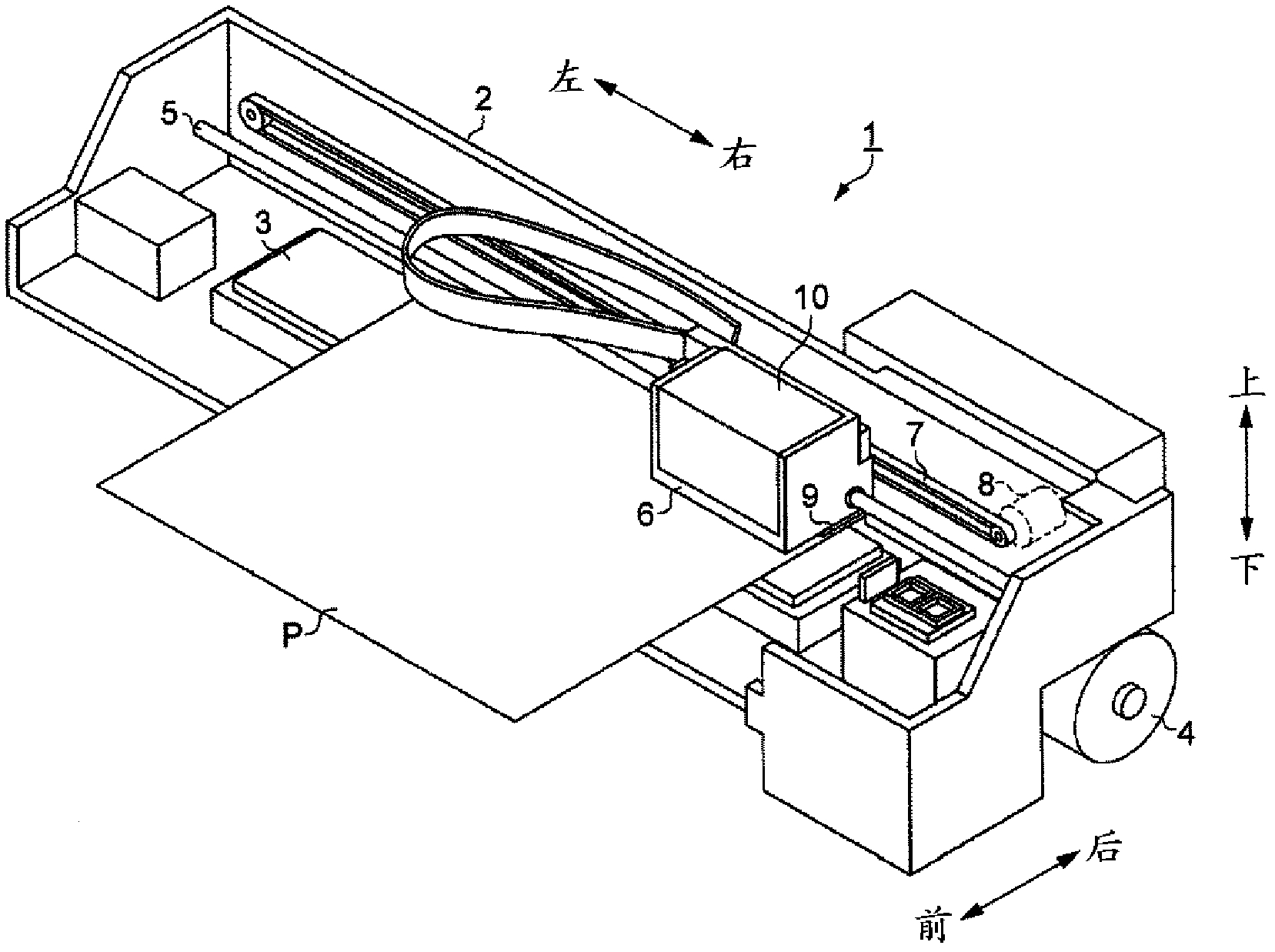

Image

Examples

Embodiment A

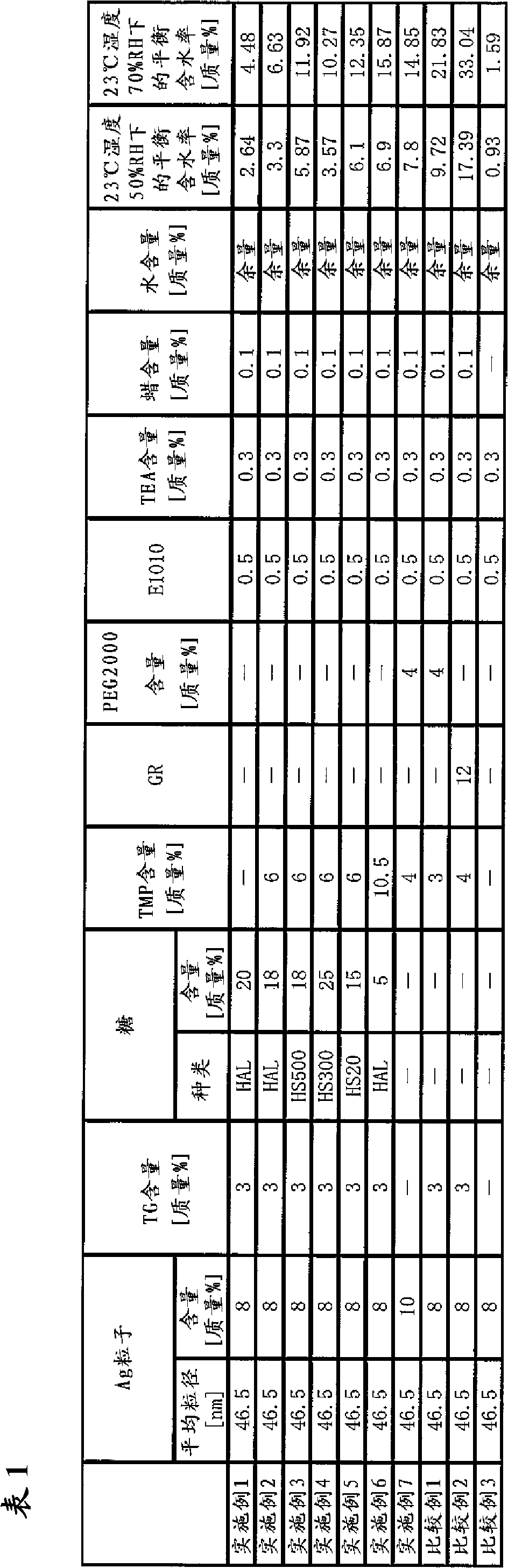

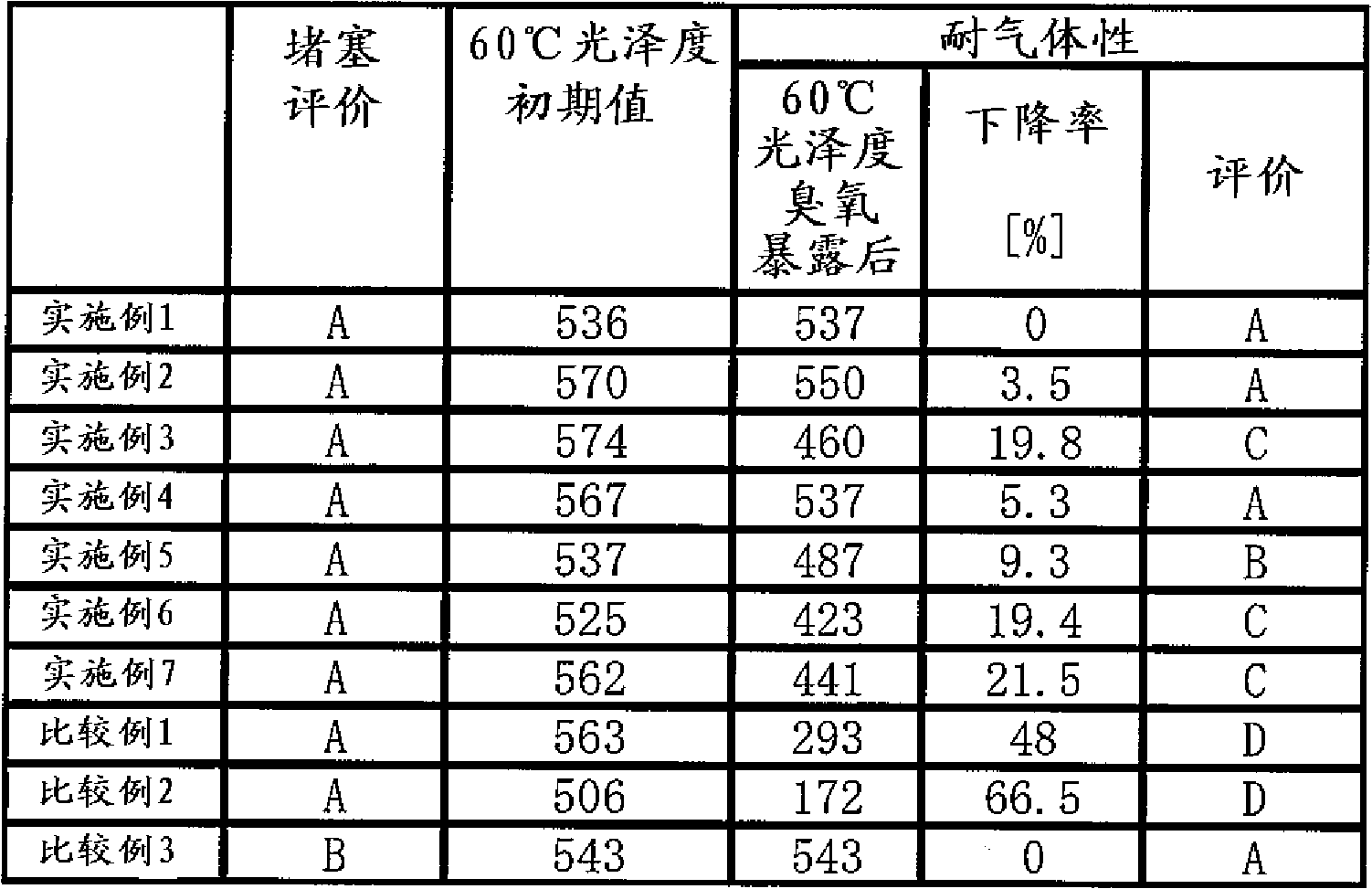

[0129] Next, specific examples of the present invention will be described.

[0130] [1] Preparation of ink composition

Embodiment 1

[0132] Polyvinylpyrrolidone (PVP, weight average molecular weight: 10,000) was heated at 70° C. for 15 hours, and then cooled at room temperature. 1000 g of this PVP was added to 500 ml of ethylene glycol solution to prepare a PVP solution. Add 500ml of ethylene glycol into another container, and add 128g of silver nitrate and fully stir with an electromagnetic stirrer to prepare a silver nitrate solution. While stirring the PVP solution with an overhead mixer at 120°C, silver nitrate solution was added, and the reaction was carried out by heating for about 80 minutes. And, thereafter, it was cooled at room temperature. The obtained solution was centrifuged at 2200 rpm for 10 minutes with a centrifuge. Then, the separated silver particles were taken out and added to 500ml ethanol solution to remove the remaining PVP. Next, centrifugation is performed again to take out the silver particles. Furthermore, the silver particle which took out was dried on the conditions of 35 de...

Embodiment 2~7

[0136] An ink composition was prepared in the same manner as in Example 1 above except that the composition shown in Table 1 was adjusted by adjusting the types and usage amounts of the components used to prepare the ink composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com