Lighting device having electric discharge lamp which has electric discharge vessel capable of forming flat screw member

A technology for lighting devices and discharge vessels, applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of position tolerance, difficulty, unfavorable height of lighting device structure, etc., to prevent damage and prevent electrical contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Identical or identically acting elements are provided with the same reference symbols in the figures.

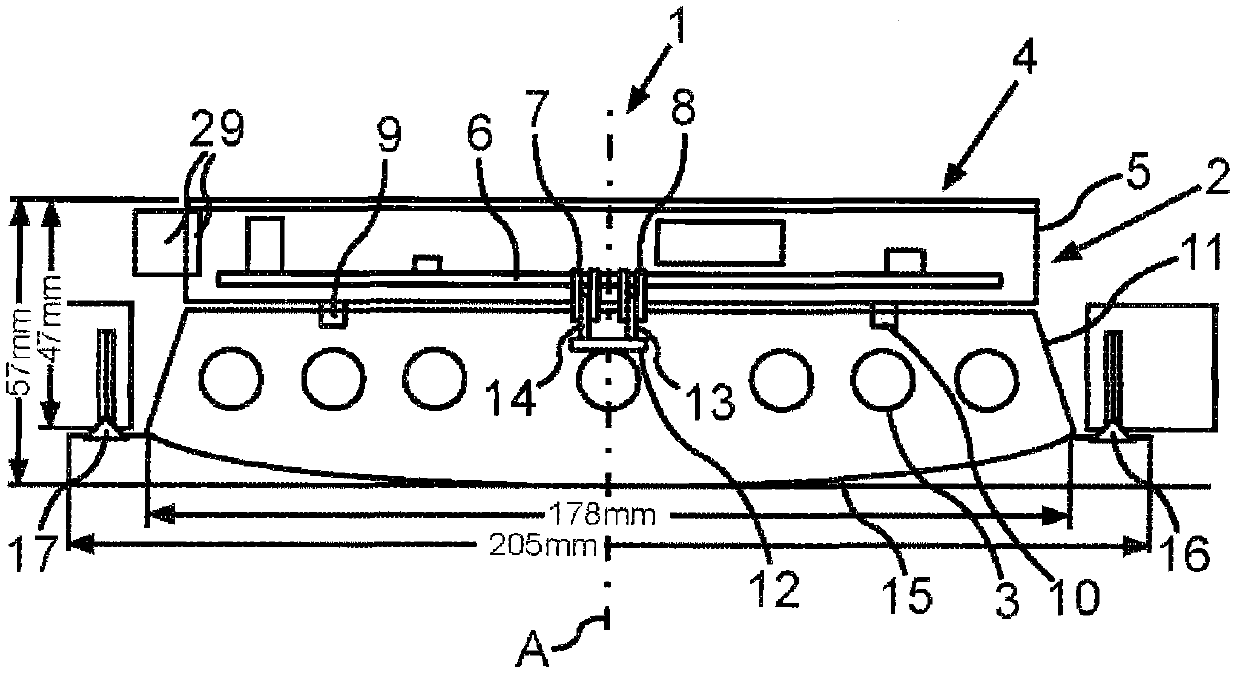

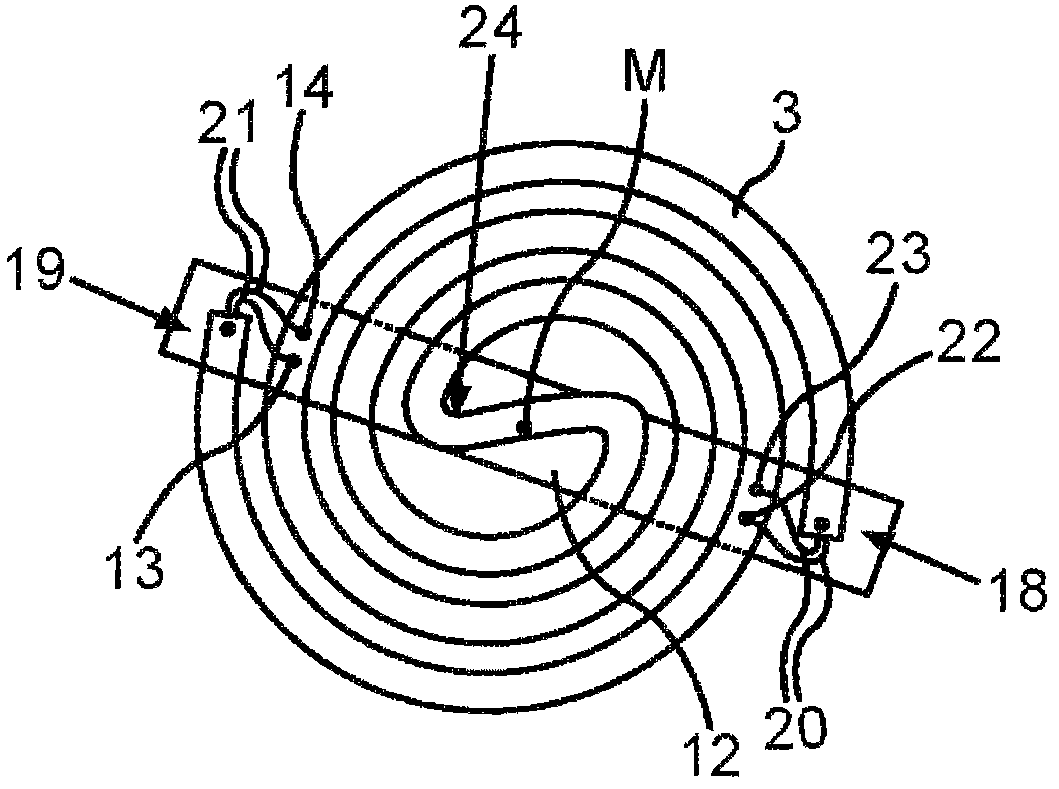

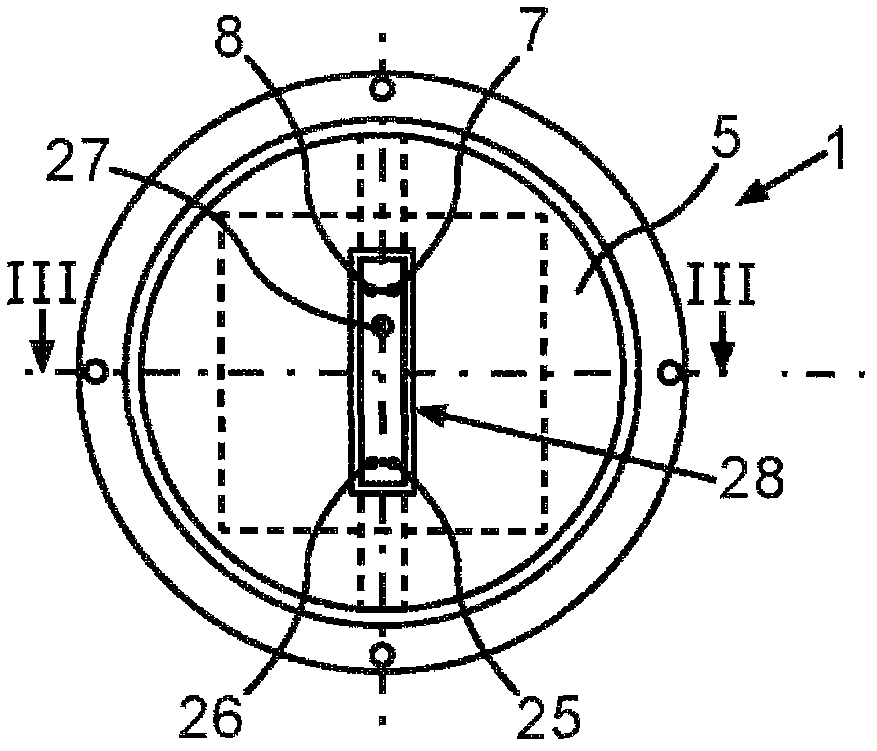

[0028] exist figure 1 A schematic sectional view of a lighting device 1 with an integrated discharge lamp 2 is shown in . The discharge lamp 2 comprises a discharge vessel 3 which is formed as a tubular and double-wound tube in two planes, said tube having feed leads protruding at its ends; The contact carrier 12 on the part has contact pins 13, 14, 22 and 23 fixed thereon. The discharge vessel 3 extending in a plane is thus formed as a flat spiral. The discharge vessel 2 is therefore also denoted as a flat lamp in the context of the present invention. Furthermore, an electronic driver 4 is arranged downstream of the discharge vessel 3 in the direction of the longitudinal axis A of the lighting device 1 . The driver 4 embodied as an electronic ballast comprises a housing 5 . A printed circuit board or circuit carrier 6 is arranged in the housing. A plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com