Novel GIS main bus

A technology of combining electrical appliances and main busbars, applied in busbar/circuit layout, electrical components, switchgear, etc., can solve the problems of large installation, commissioning and maintenance workload, large gas consumption, high gas insulation cost, and achieve no high voltage exposure point. , Low cost, the effect of reducing the amount of SF6 gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

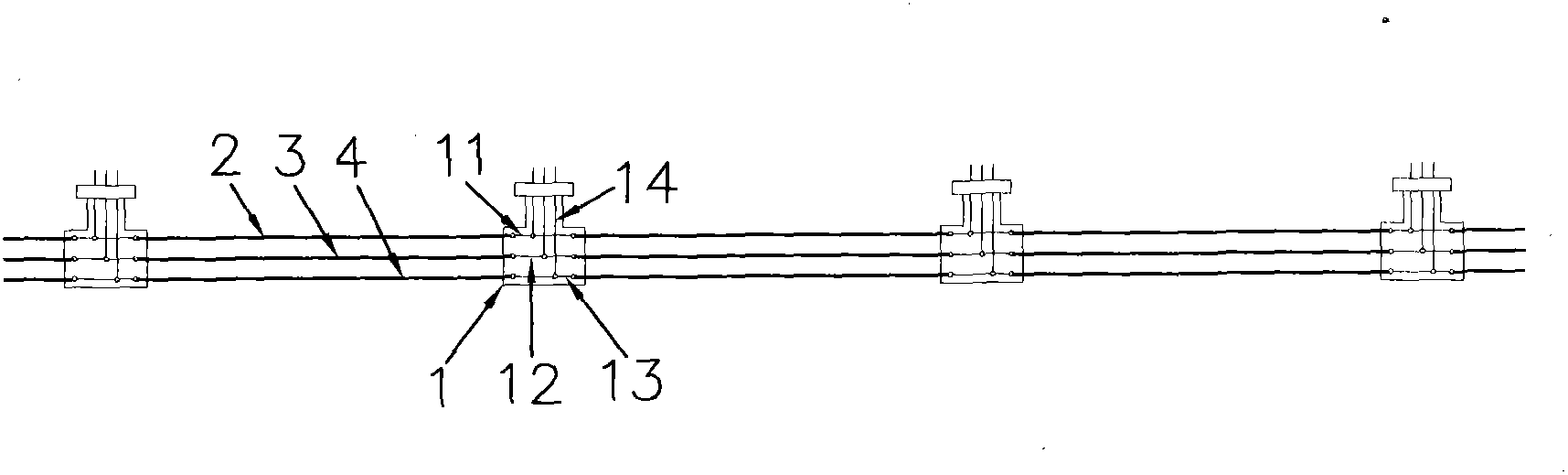

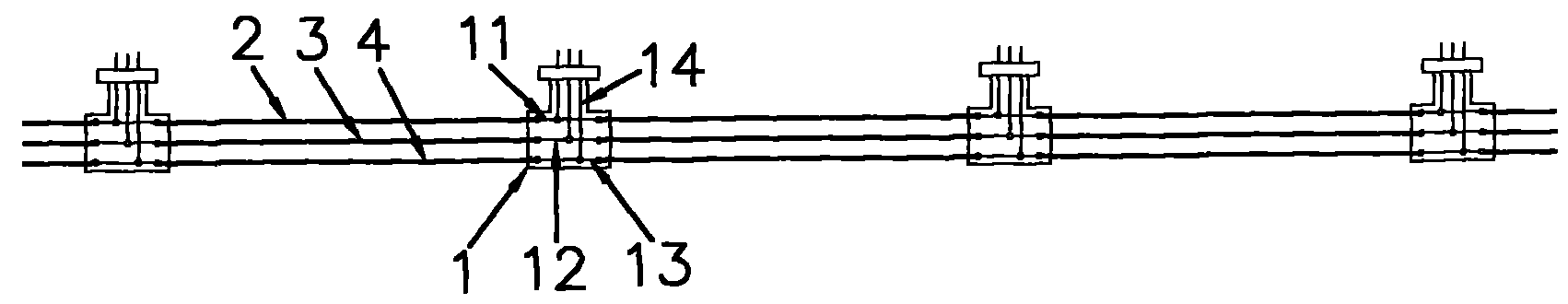

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in combination with the embodiments and accompanying drawings.

[0014] Please refer to figure 1 , the main busbar of the new combination electrical appliance of the present invention includes SF 6 Metal tank with gas as insulating medium 1, A-phase capacitive insulating bus bar 2, B-phase capacitive insulating bus bar 3, C-phase capacitive insulating bus bar 4, A-phase capacitive insulating bus bar 2, B-phase capacitive insulating bus bar 3, C Phase capacitance type insulated busbar 4 through SF 6 The metal tank 1 with gas as the insulating medium is connected to the spaced butt joint part (not shown in the figure) of the combined electrical appliance.

[0015] Preferably, the A-phase capacitive insulated bus 2, the B-phase capacitive insulated bus 3, and the C-phase capacitive insulated bus 4 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com