Rotary device

A technology of rotating devices and rotating shafts, which is applied in the direction of electromechanical devices, driving devices, feeding devices, etc., can solve the problems of time-consuming rotating devices and difficulty in ensuring the coaxiality of rotating motors, and achieve the goal of ensuring coaxiality and efficient assembly operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

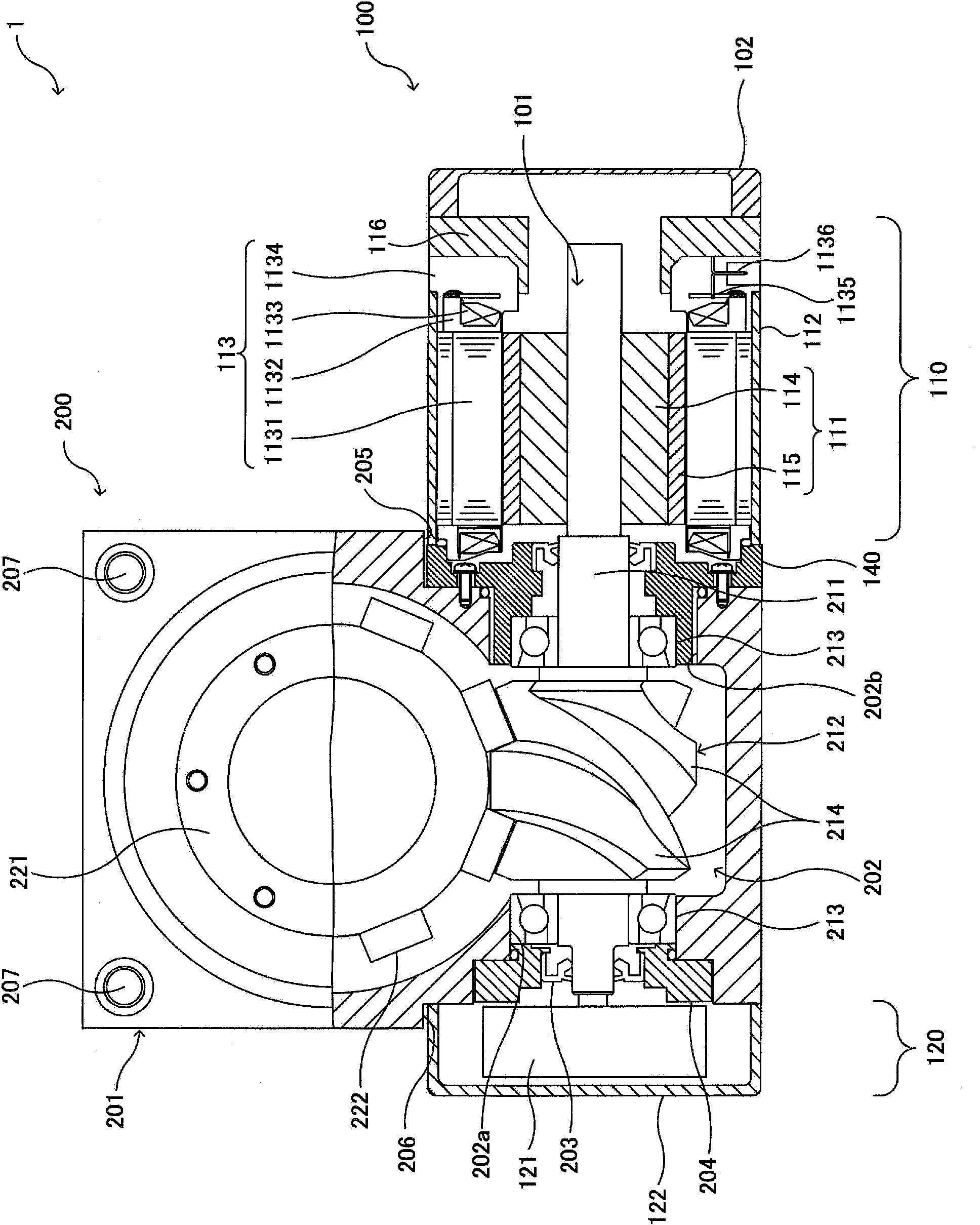

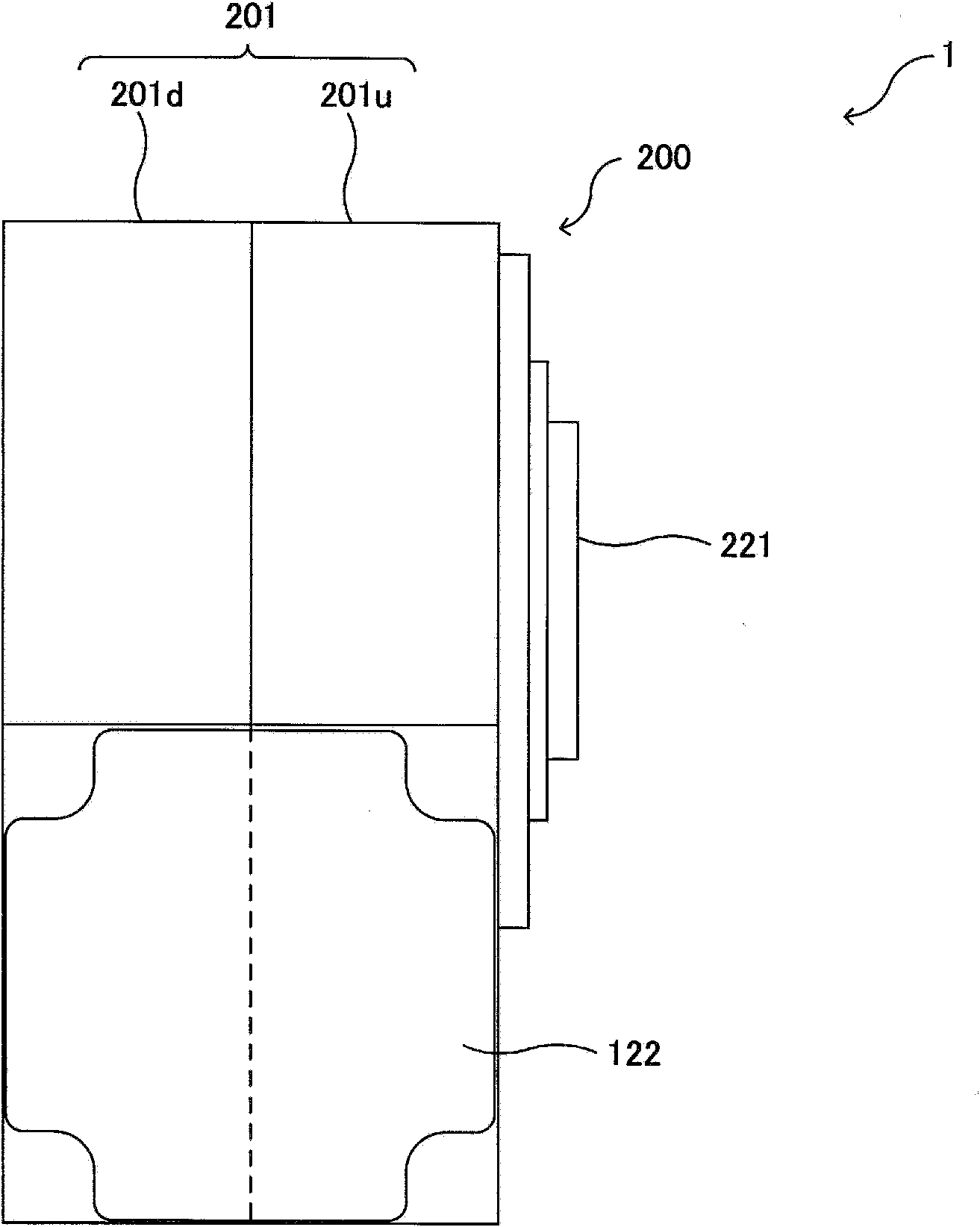

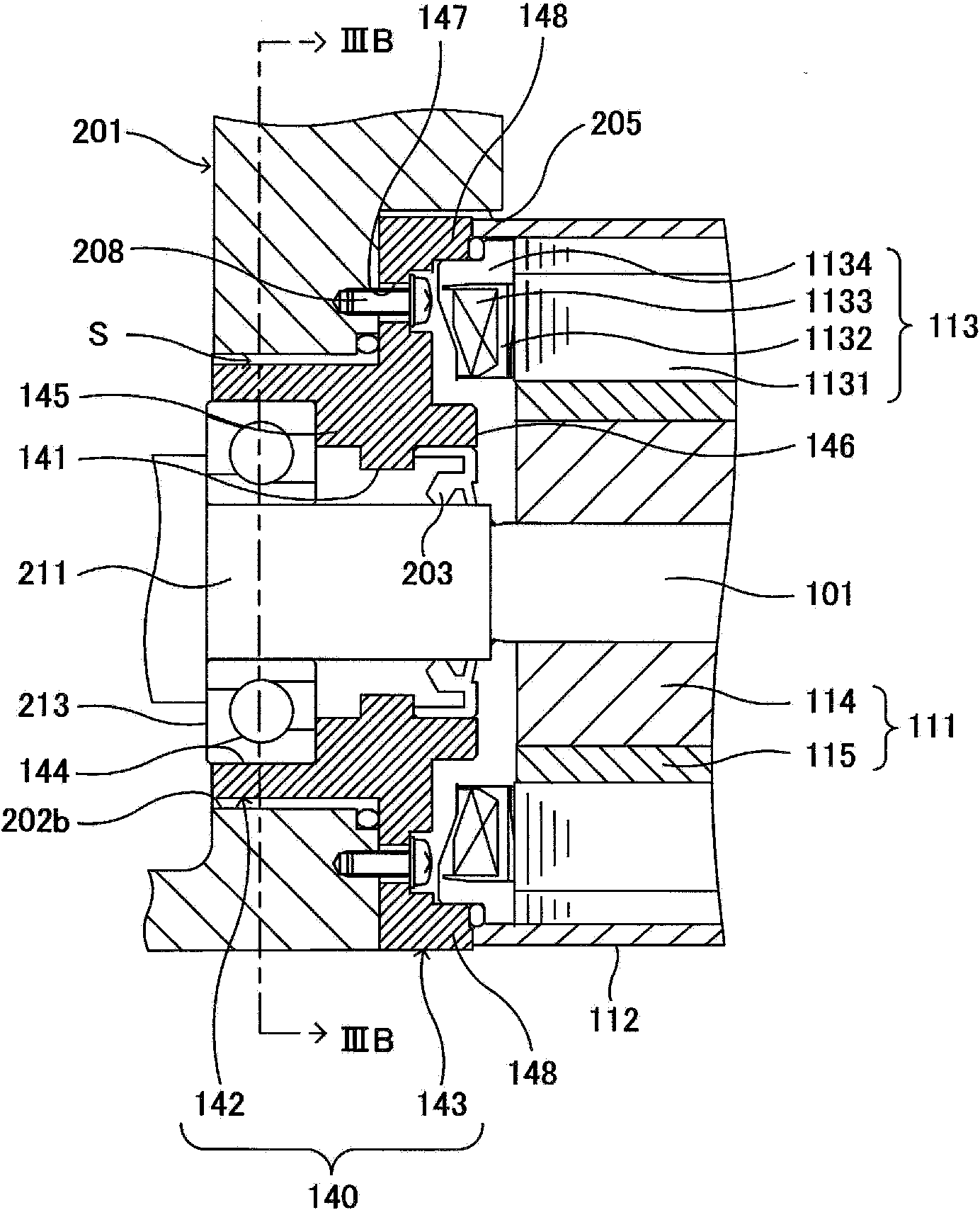

[0021] First, use figure 1 and figure 2 The overall structure of the rotating device as one embodiment of the present invention will be described. figure 1 It is a vertical cross-sectional view showing the overall structure of a rotating device as an embodiment of the present invention. figure 2 It is a side view showing the overall structure of the rotating device as one embodiment of the present invention, viewed from the encoding unit side.

[0022] like figure 1 As shown, the rotary device 1 integrally includes a motor 100 as a rotary electric machine and a speed reducer 200 . The motor 100 has a motor electromagnetic unit 110 and an encoder unit 120 . A speed reducer 200 is disposed between the motor electromagnetic unit 110 and the encoder unit 120 .

[0023] The motor electromagnetic unit 110 includes a rotor 111 and a stator 113 . The rotor 111 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com