Cylinder-moving type pressing machine for sleeve cylinder

A technology of a cylinder and a press, which is applied to the field of cylinder-driven presses, can solve the problems that the press cannot take into account pressure, speed classification and low energy consumption, and achieve the effects of light weight and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

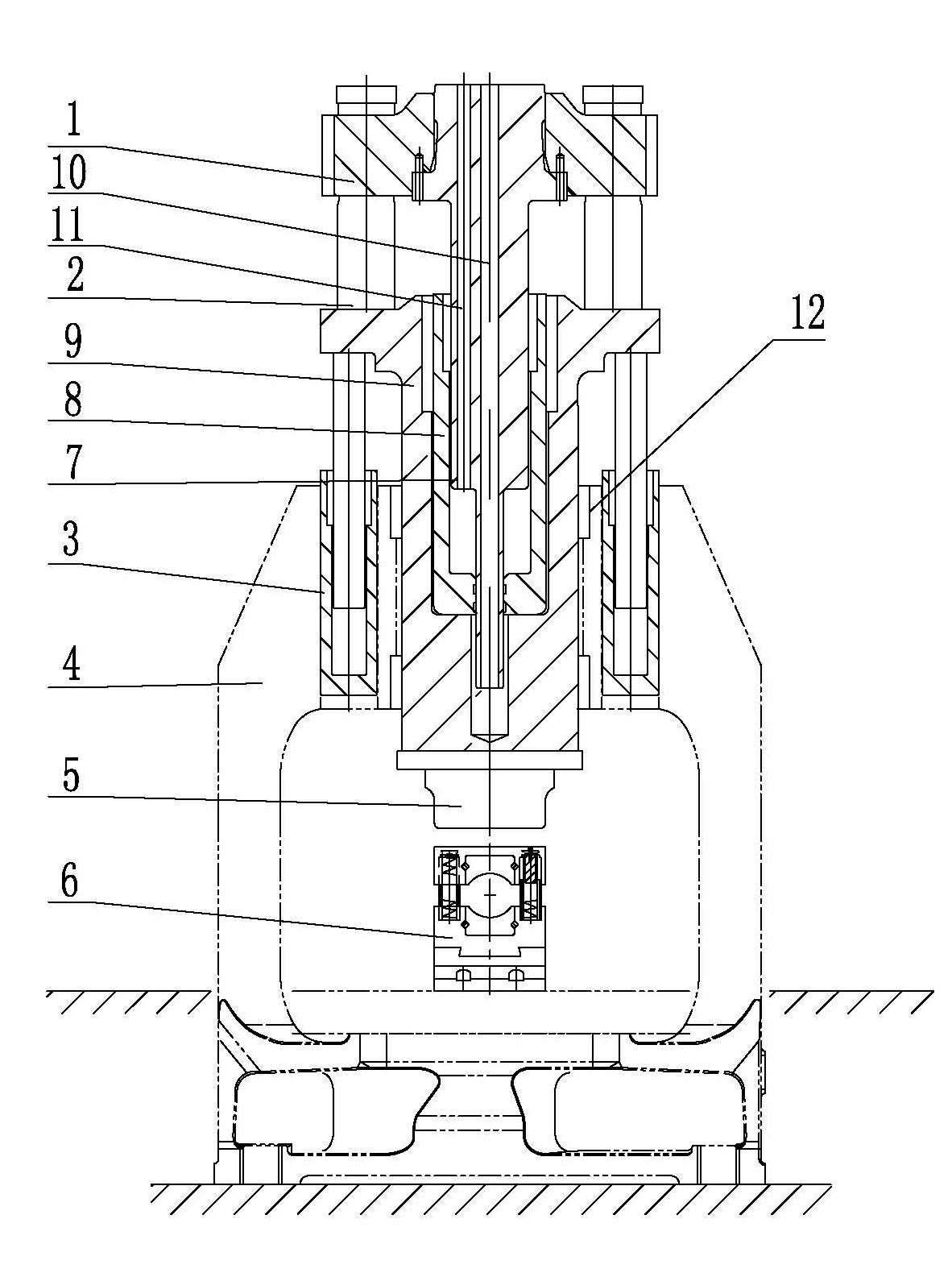

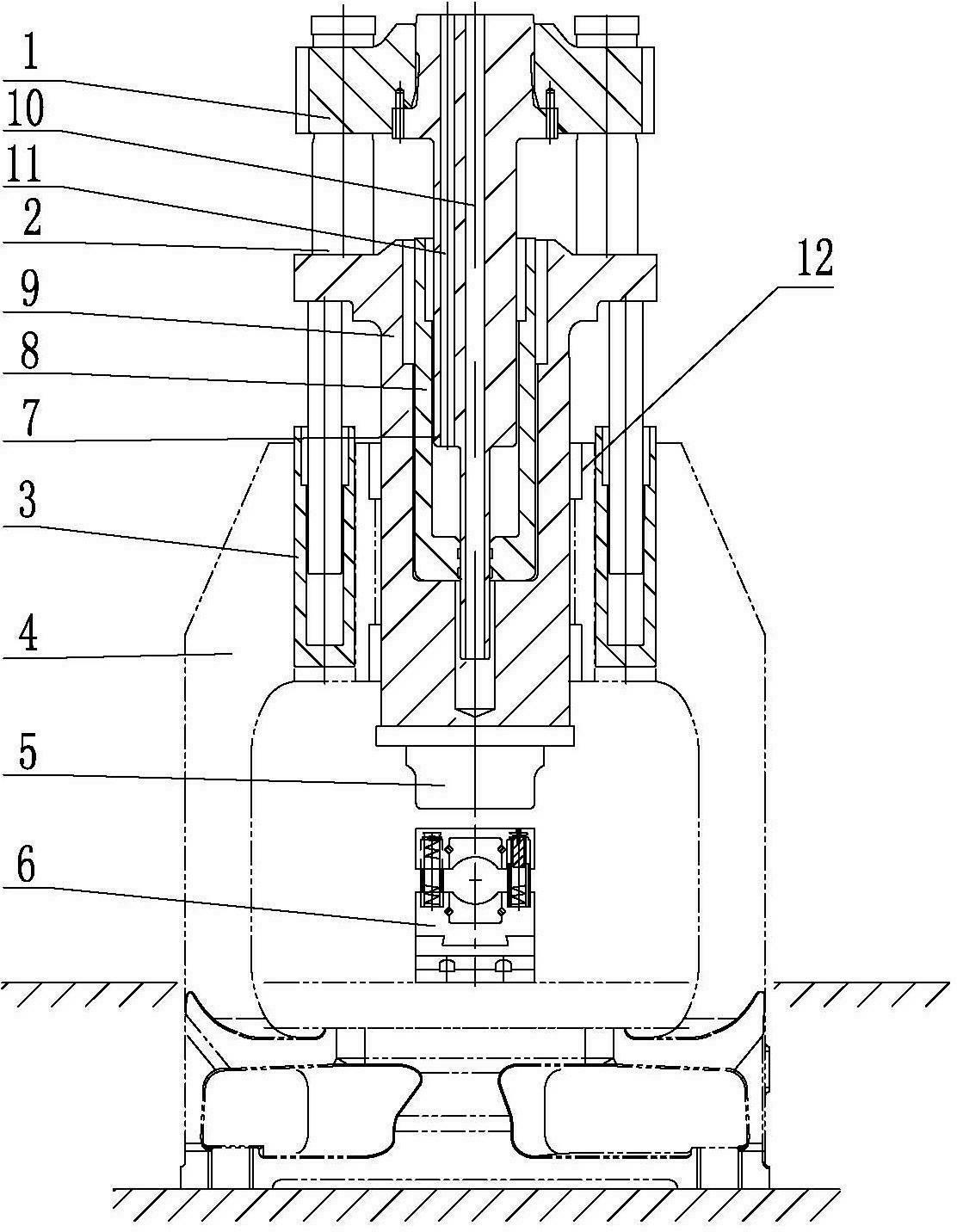

[0012] In the figure, the upper beam 1 is fixedly connected with the frame 4 through four pull rods 2 . The flange on the fixed plunger 7 outer diameters is fixed in the groove of the upper beam 1 bottom surface by bolts, and the upper end surface of the fixed plunger 7 is higher than the upper top surface of the upper beam 1 . The fixed plunger 7 is slidably matched with the central inner cavity of the movable plunger 8 through the sealing ring, and the outer diameter of the movable plunger 8 is slidably matched with the central inner cavity of the main cylinder 9 through the sealing ring. The opening of the master cylinder 9 is upward. The outer surface of the main cylinder 9 is in a tetrahedral shape, and correspondingly, the frame 4 has an inner hole in a tetrahedral shape, and the inner hole on the frame 4 is inlaid with a guide plate 12, and the guide plate 12 is in contact with the main cylinder 9. The outer surface of the sliding fit. The cylinder body of the return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com