High-frequency communication optical fiber polishing method and polishing device

An optical fiber and communication technology, which is applied in the field of high-frequency communication optical fiber grinding methods and grinding devices, can solve the problems of inability to guarantee the smoothness and smoothness of grinding, affecting the production of the unit, and taking a long time to troubleshoot, so as to solve the problem of optical fiber in the control system. The effect of communication failure, improving the efficiency of grinding and maintenance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

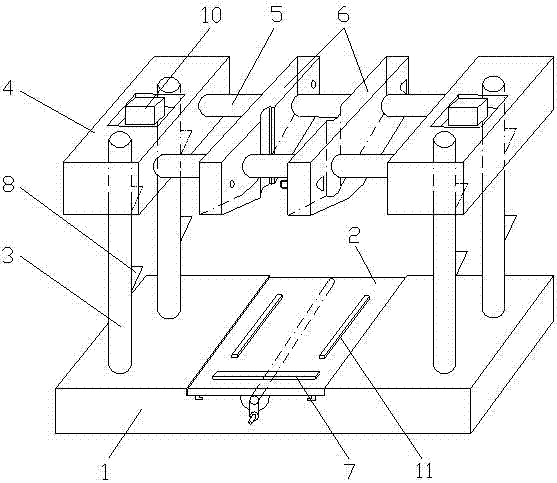

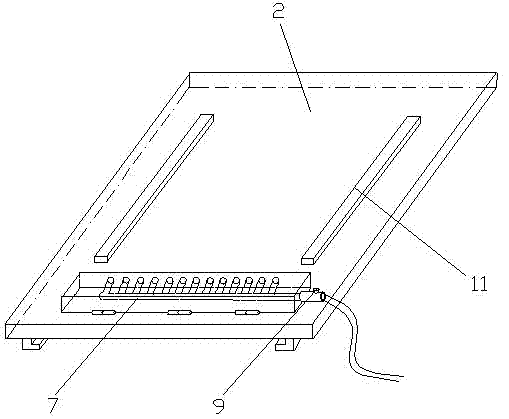

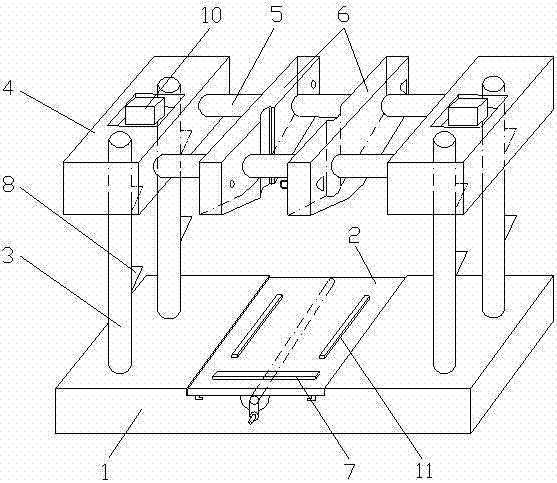

[0026] Such as figure 1 , 2 As shown, a high-frequency communication optical fiber grinding device includes a base 1, a grinding platform 2, a longitudinal guide rod 3, a vertically moving slider 4, a transverse guide rod 5, an optical fiber clamp 6 and a blowing device 7; The longitudinal guide rod 3 is fixed on the base 1, the vertically moving slider 4 is installed on the longitudinal guide rod 3, the moving slider 4 and the longitudinal guide rod 3 form a moving pair, and the longitudinal guide rod 3 is provided with an elastic support piece 8, which moves vertically The slider 4 is supported by the elastic support piece 8 when it is in the upper position; the lateral guide rod 5 is fixed on the moving slider 4, the optical fiber clamp 6 is installed on the lateral guide rod 5, and the lateral guide rod 5 and the optical fiber clamp 6 It constitutes a moving pair; the base 1 is provided with a chute directly below the optical fiber fixture 6, the grinding platform 2 is se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap