Swinging bed type shot blasting processor

A processing machine and swinging bed type technology, applied in the field of casting equipment, can solve the problems of handling costs, inability to continue production, and affecting processing efficiency, etc., and achieve the effect of reducing handling costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

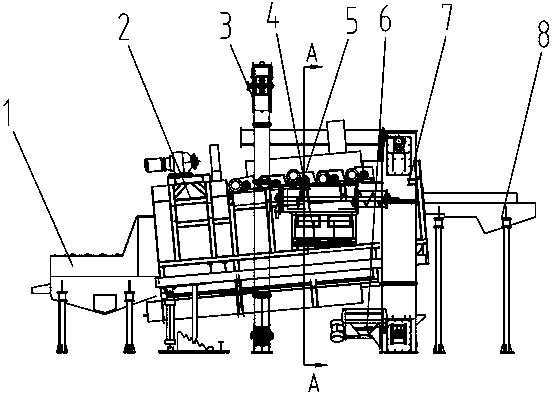

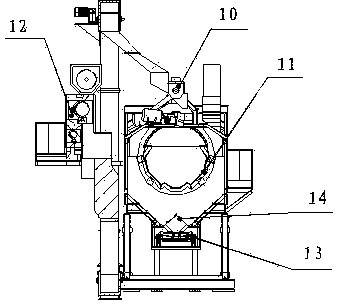

[0022] According to attached figure 1 with 2 It can be seen that the present invention specifically relates to a swing bed type shot blasting machine, comprising a swing bed 7, a shot blaster, a screw feeder 10, a hoist, a sand and shot separator 6, and a feeding vibrating bed 9 fixed on the ground and The discharge vibrating bed 1, two hoists are arranged on both sides of the middle of the feeding vibrating bed 9 and the discharging vibrating bed 1, which are No. 1 hoist 8 and No. 2 hoist 3 respectively.

[0023] The swing bed 7 is located below the bed bodies of the feeding vibrating bed 9 and the discharging vibrating bed 1. The swing bed 7 is cylindrical with a diameter of 600 mm to 2500 mm, and the swing bed 7 is placed obliquely. One end of the material vibration table 9 is higher than the end close to the discharge vibration table 1. The inclination angle of the swing bed 7 is 2 to 20 degrees. The inclination angle of the swing bed 7 can be adjusted. 7 are connected o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com