High-pressure air force flow-assistant cabin clearing equipment and cabin clearing method thereof

A kind of pneumatic, clearing technology, applied in the direction of container, packaging, transportation and packaging, etc., can solve the problem of hydraulic system prone to problems, blockage, and the lower part cannot be cleared, and achieve the effect of eliminating blockage factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

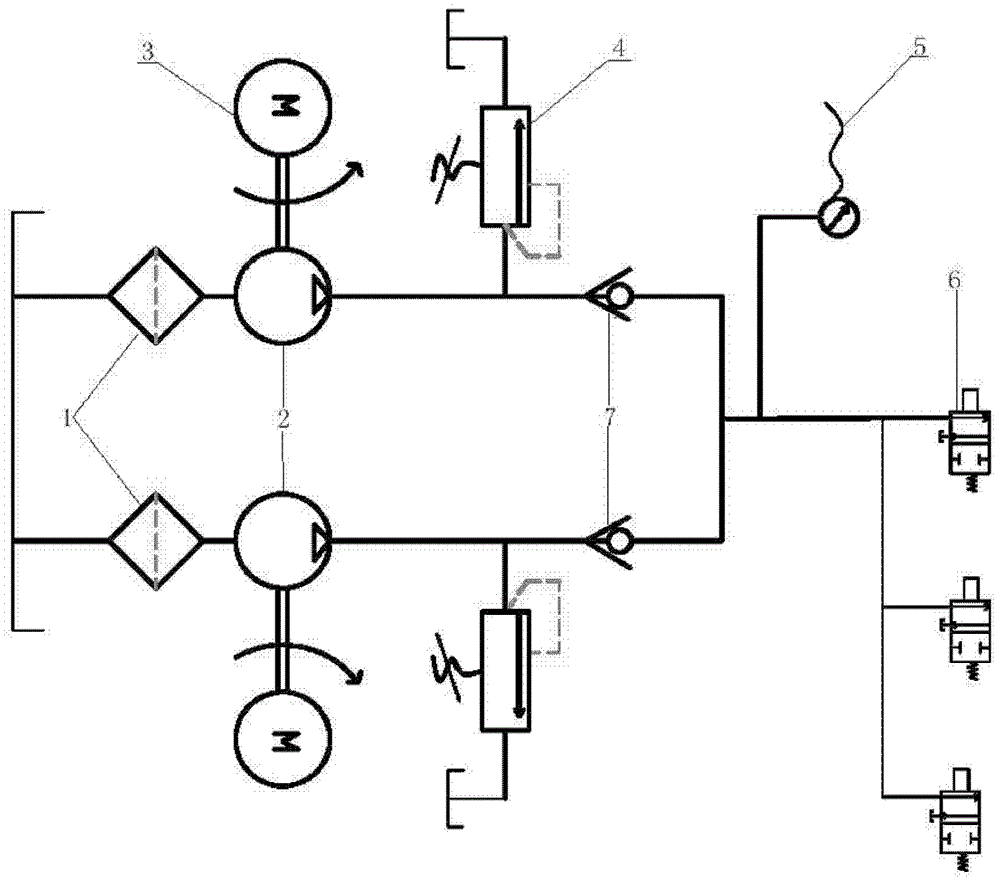

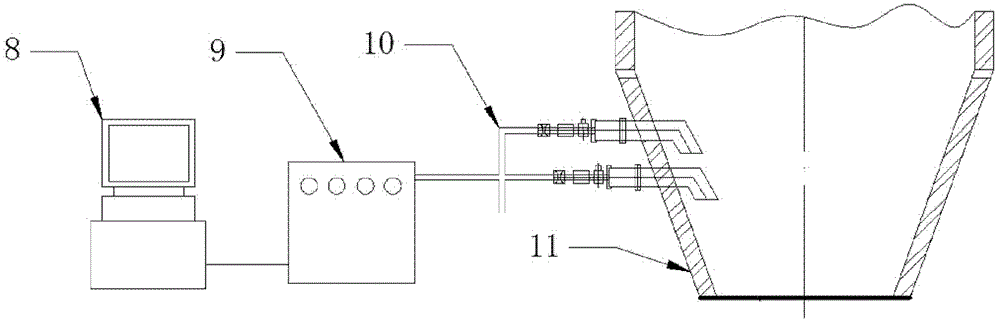

[0020] Such as figure 1 The high pressure water auxiliary system shown, consists of figure 2 Controlled by the controller 8 in the water pump 2, the water is transported into the silo 11 through the pipeline system 10. Depend on figure 1 It can be seen that the system is a parallel system, and the system can still operate normally even if a transmission line is damaged. This system is an auxiliary part of the pneumatic system to increase the airtightness of materials, thereby enhancing the effectiveness of pneumatic work.

[0021] exist figure 2 Among them, a high-pressure air-assisted flow-assisted clearing equipment is mainly composed of a controller 8, an air compressor 9, a pipeline system 10, and the like.

[0022] Described controller 8 is made up of cabinet, touch screen and PLC etc. The touch screen provides a friendly full Chine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com