Lifting mechanism for shuttling tool

A lifting mechanism and shuttle car technology, which is applied to the lifting mechanism of cargo storage and retrieval shuttle cars, and the field of lifting mechanisms for shuttle cars, which can solve the problems of high manufacturing cost, large power consumption, unreliable self-locking starting torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

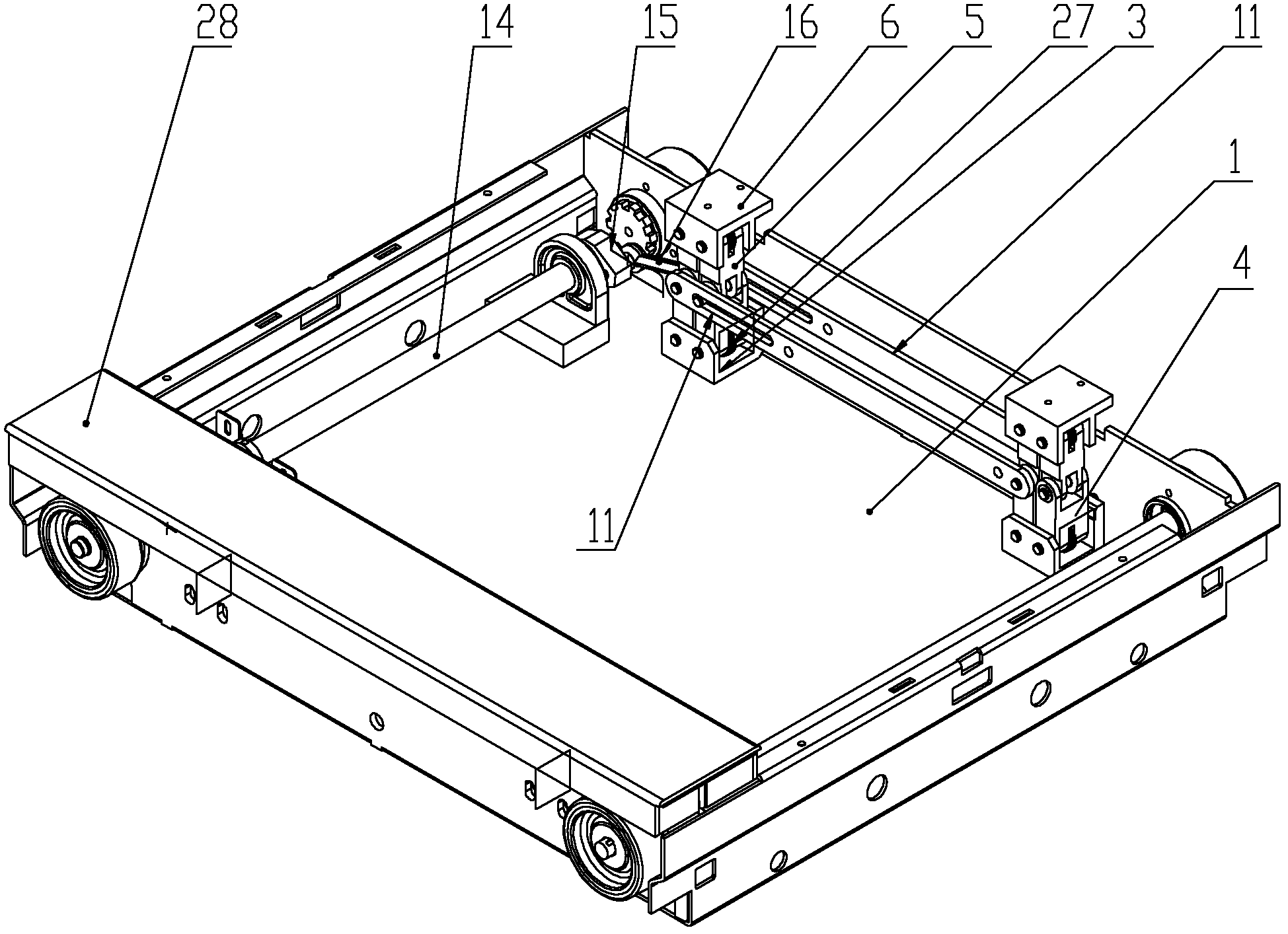

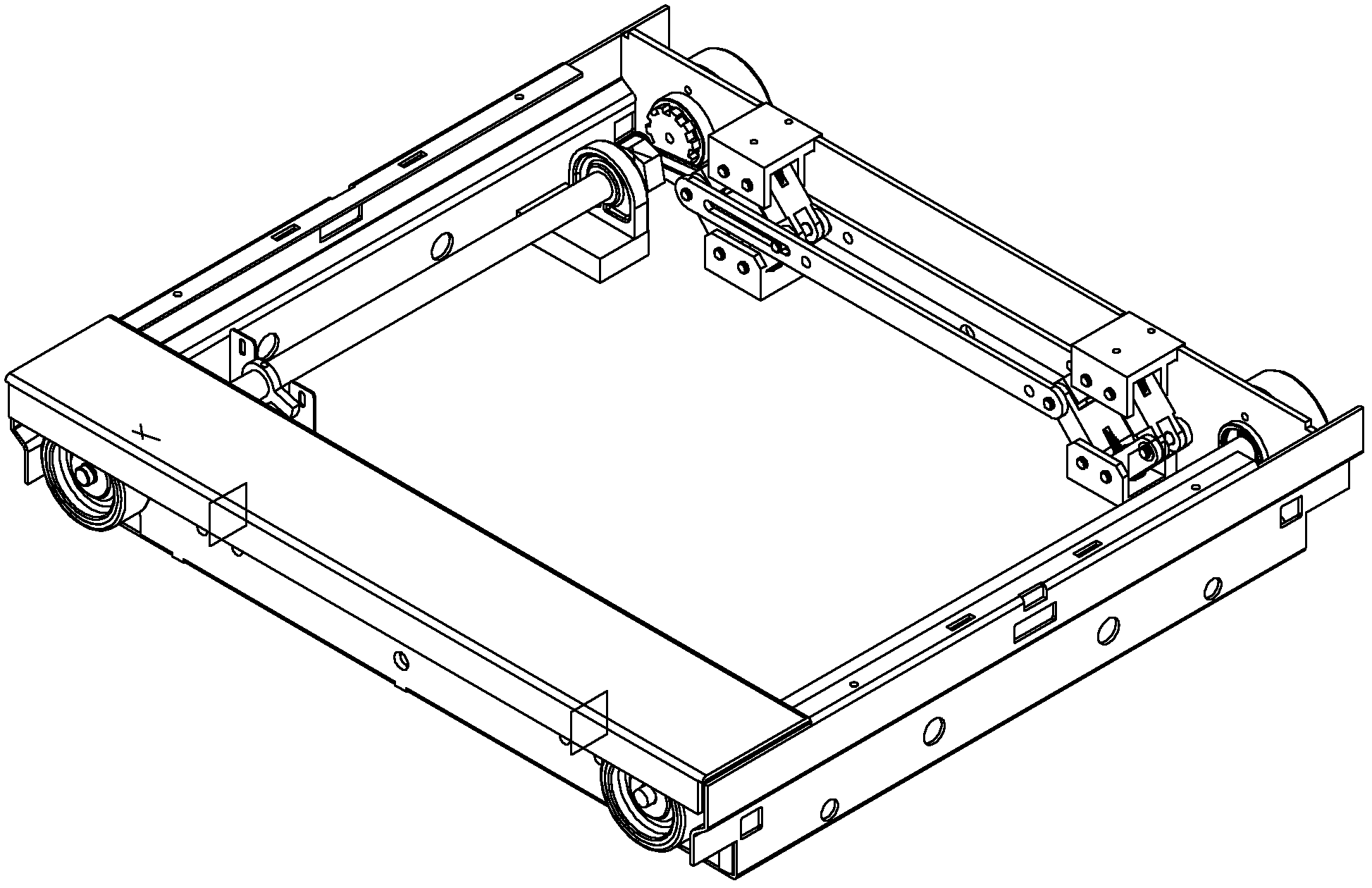

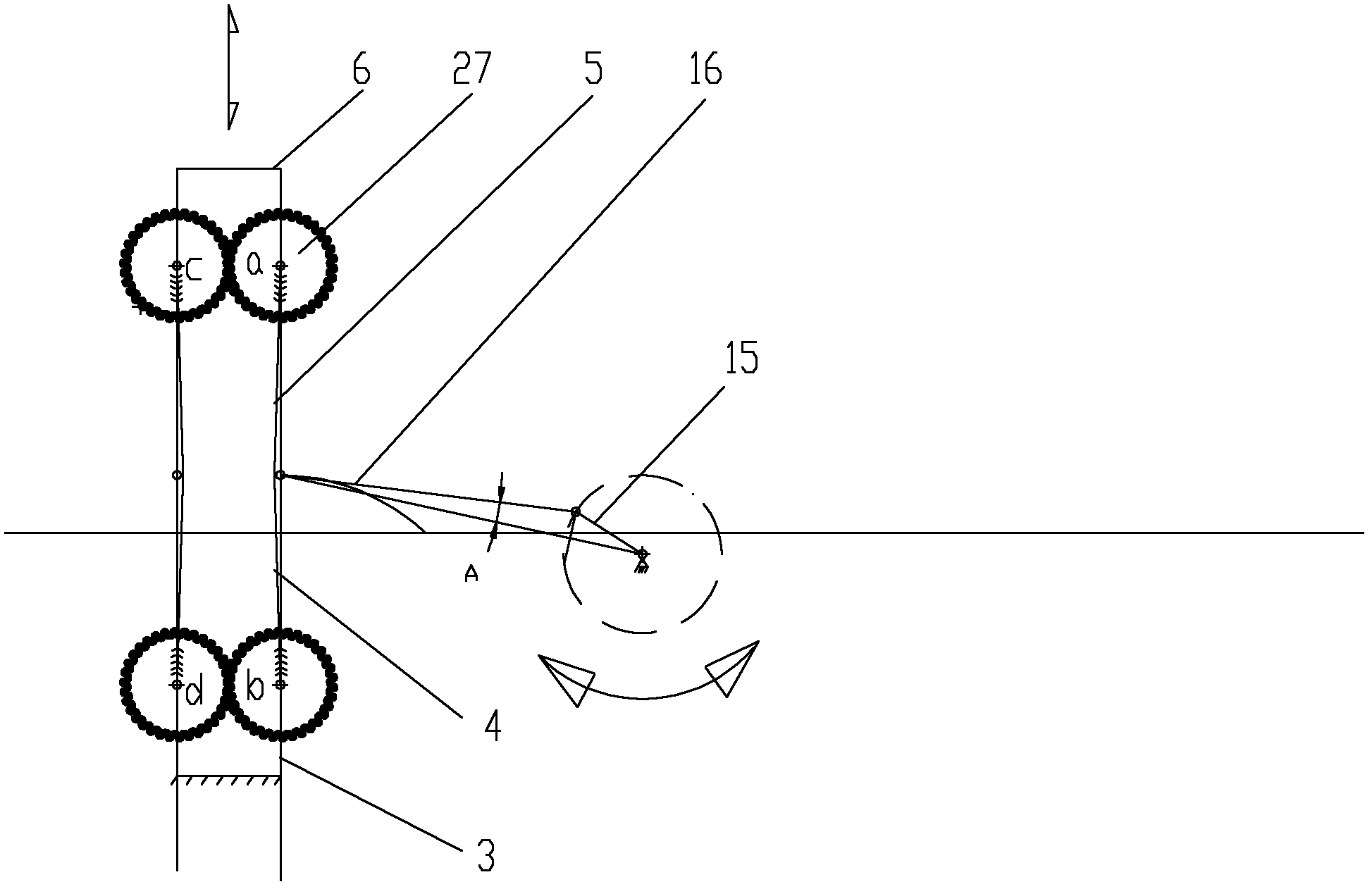

[0014] The hoisting mechanism of this embodiment is as figure 1 (see image 3 ), the four corners of the bottom frame 1 of the shuttle are respectively fixed with a lifting base 3 with the notch facing upward, and each lifting base 3 has a lifting top fixed with the tray top plate 28 on both sides and the notch facing downward. Seat 6. Each lifting base 3 and lifting top base 6 respectively have a pair of mutually meshing synchronous gears 27 whose rotation centers are on the same horizontal line.

[0015] The four synchronous gear rotation centers in the lifting base 3 and the lifting top base 6 in the upper corner of the figure are fixedly connected with one end of a pair of lower rocker arms 4 and a pair of upper rocker arms 5 respectively, and the pair of lower rocker arms 4 Correspondingly hinged with the other end of a pair of upper rocker arms 5 respectively. One of a pair of joints (outside) of a pair of lower rocker arms 4 and a pair of upper rocker arms 5 is hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com